Ventilation equipment with anti-blocking function for industrial furnace

A technology for industrial furnaces and ventilation equipment, applied to mechanical equipment, components of pumping devices for elastic fluids, non-variable pumps, etc., can solve problems such as blocking ventilation equipment and increasing equipment failure rates, and prevent blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

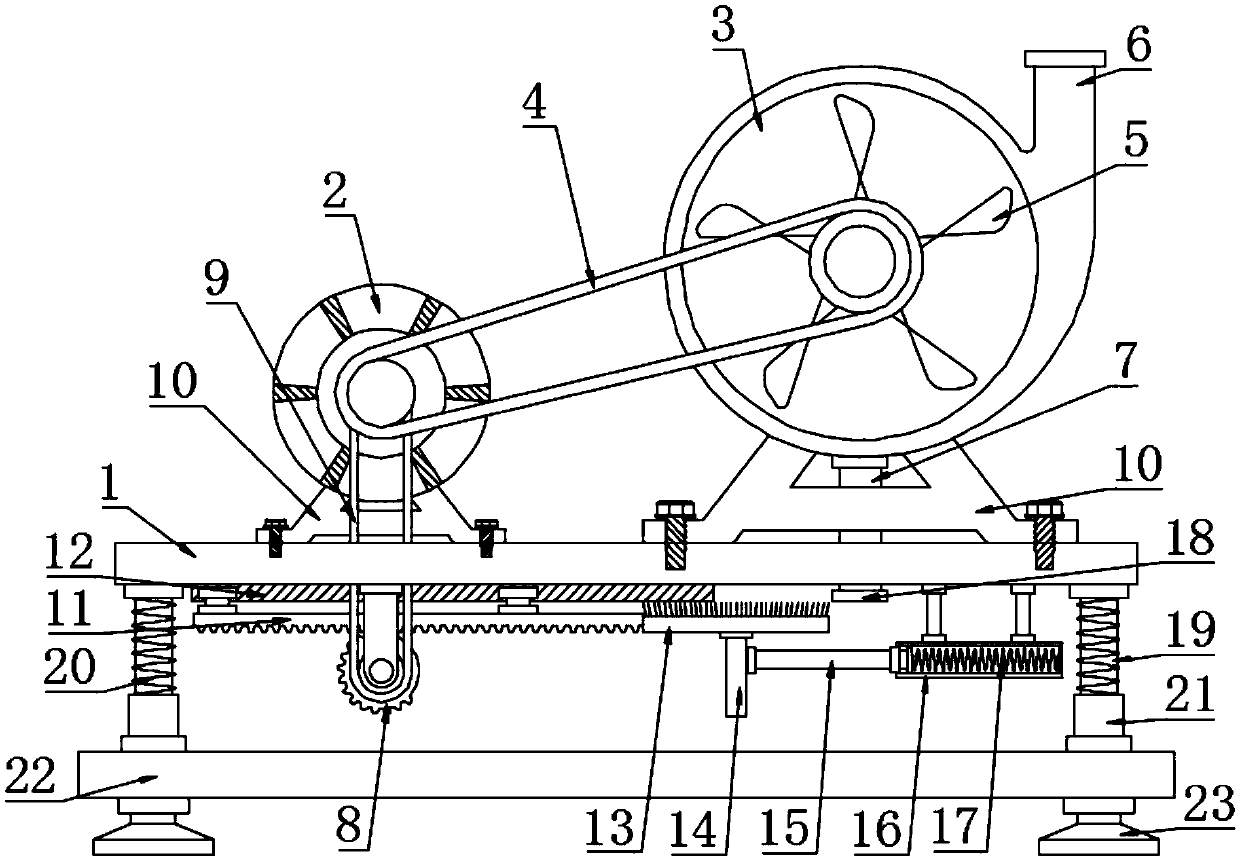

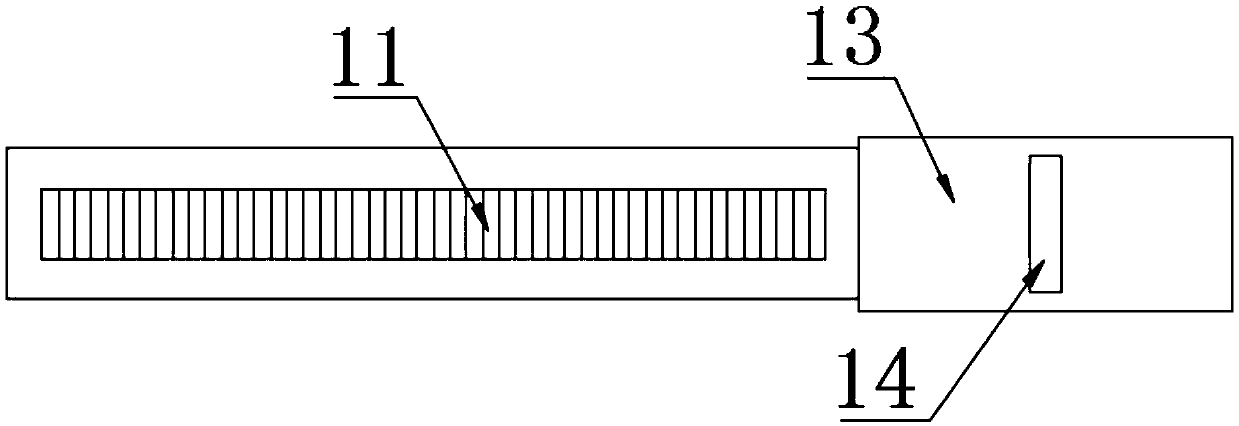

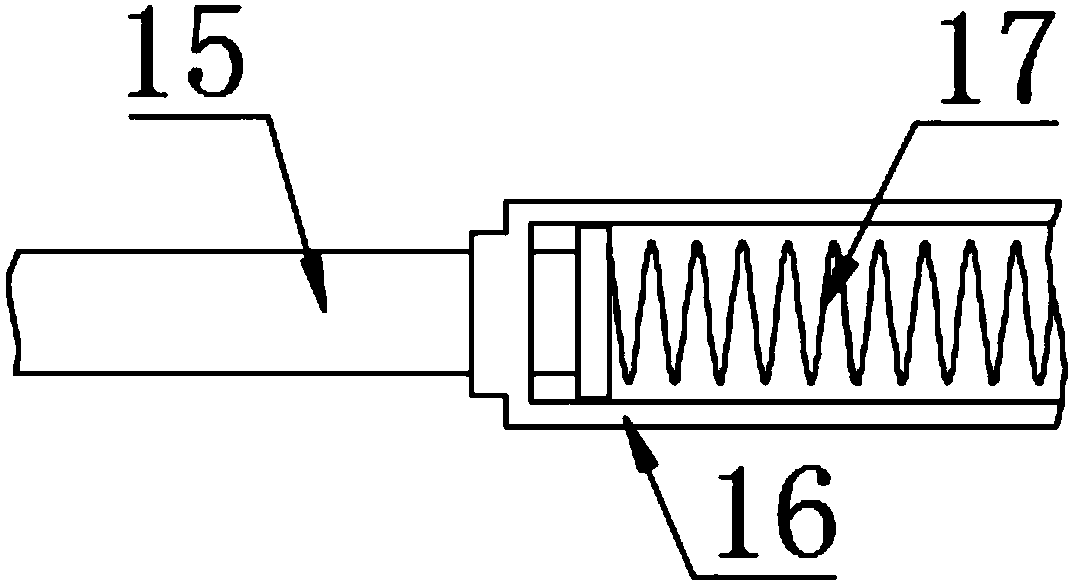

[0021] see Figure 1~4 , in an embodiment of the present invention, a ventilation device for industrial furnaces with anti-blocking function, including a mounting plate 1, a drive motor 2, an impeller 3, a tooth plate 11 and a brush plate 13; the two sides above the mounting plate 1 The driving motor 2 and the impeller 3 are respectively arranged, the lower parts of the driving motor 2 and the impeller 3 are fixedly connected to the supporting frame 10, the supporting frame 10 is fixedly connected to the mounting plate 1 by bolts, and the driving motor 2 leads are connected to the power supply and the switch, and pressing the switch makes The driving motor 2 is energized to drive the output end of the motor to rotate; the impeller 3 is internally connected to a blade 5 which is fixedly connected to the rotating shaft, and the rotating shaft is connected to the output end of the driving motor 2 through the first synchronous belt 4, and the side wall above the impeller 3 An air ...

Embodiment 2

[0024] In order to make the technical solution of this application more complete and detailed, some supplements and explanations are made on the basis of the above-mentioned embodiment 1, so that the technical means adopted in this application are disclosed more fully. Specifically, the technical characteristics of the added part are as follows: The two sides of the lower end of the mounting plate 1 are respectively fixedly connected with movable rods 19, the surface of the movable rod 19 is covered with a damping spring 20, and the lower part of the movable rod 19 is movably connected with the sleeve 21, and the lower end of the damping spring 20 abuts against the sleeve 21 , the lower end of the sleeve 21 is fixedly connected to the base plate 22, and the lower end of the base plate 22 is fixedly connected with a leg 23, and the mounting plate 1 is damped by the movable rod 19, the damping spring 20 and the sleeve 21 so as to achieve the damping effect on the impeller 3 , to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com