Anti-overturning type high-temperature corrosive medium conveying pipeline component

A technology of high temperature corrosion and medium conveying, applied in the direction of pipes/pipe joints/fittings, pipeline supports, pipeline systems, etc. The effect of fixing the installation angle, improving the quality of welding butt, and ensuring the accuracy of the horizontal position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

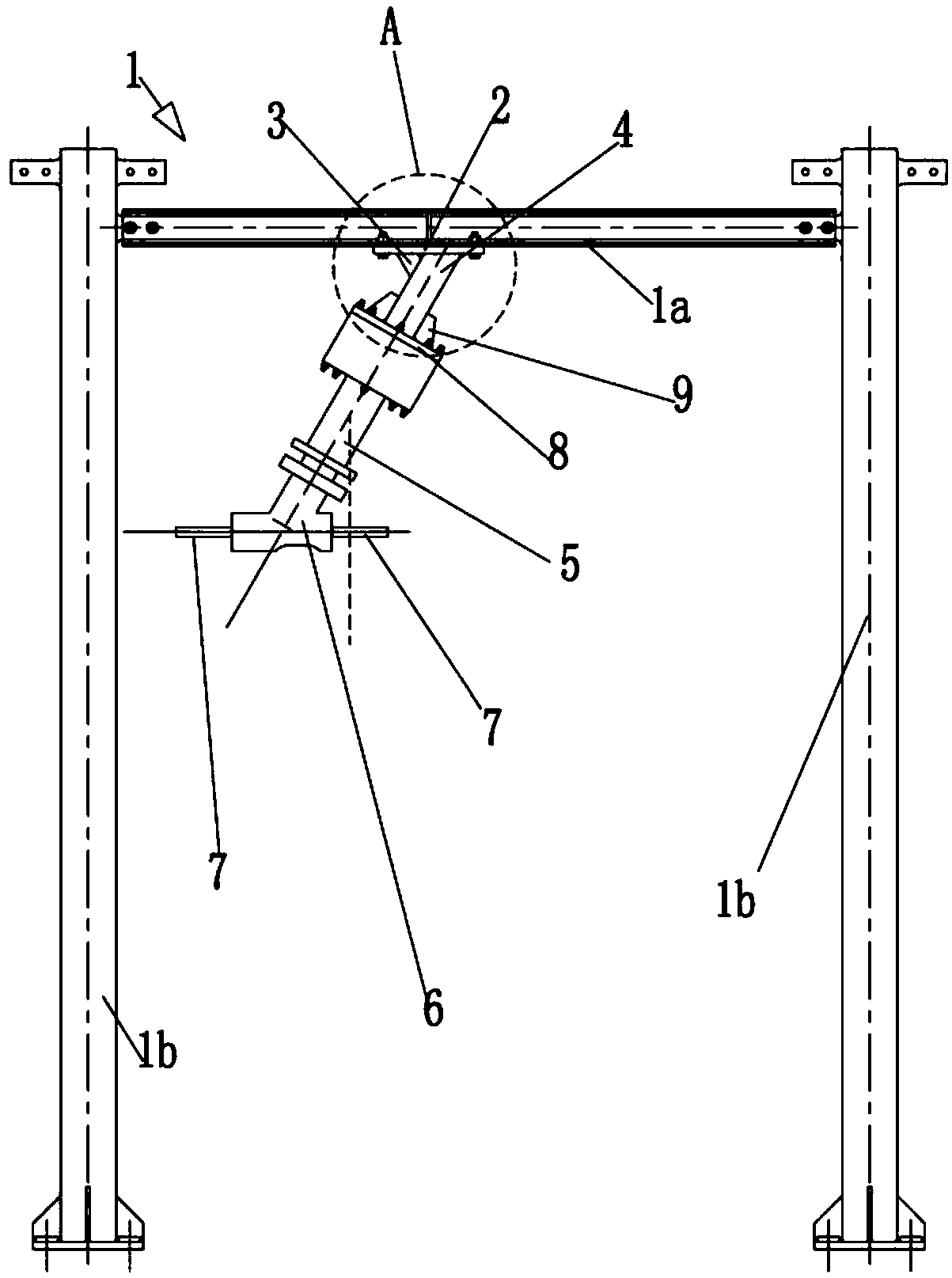

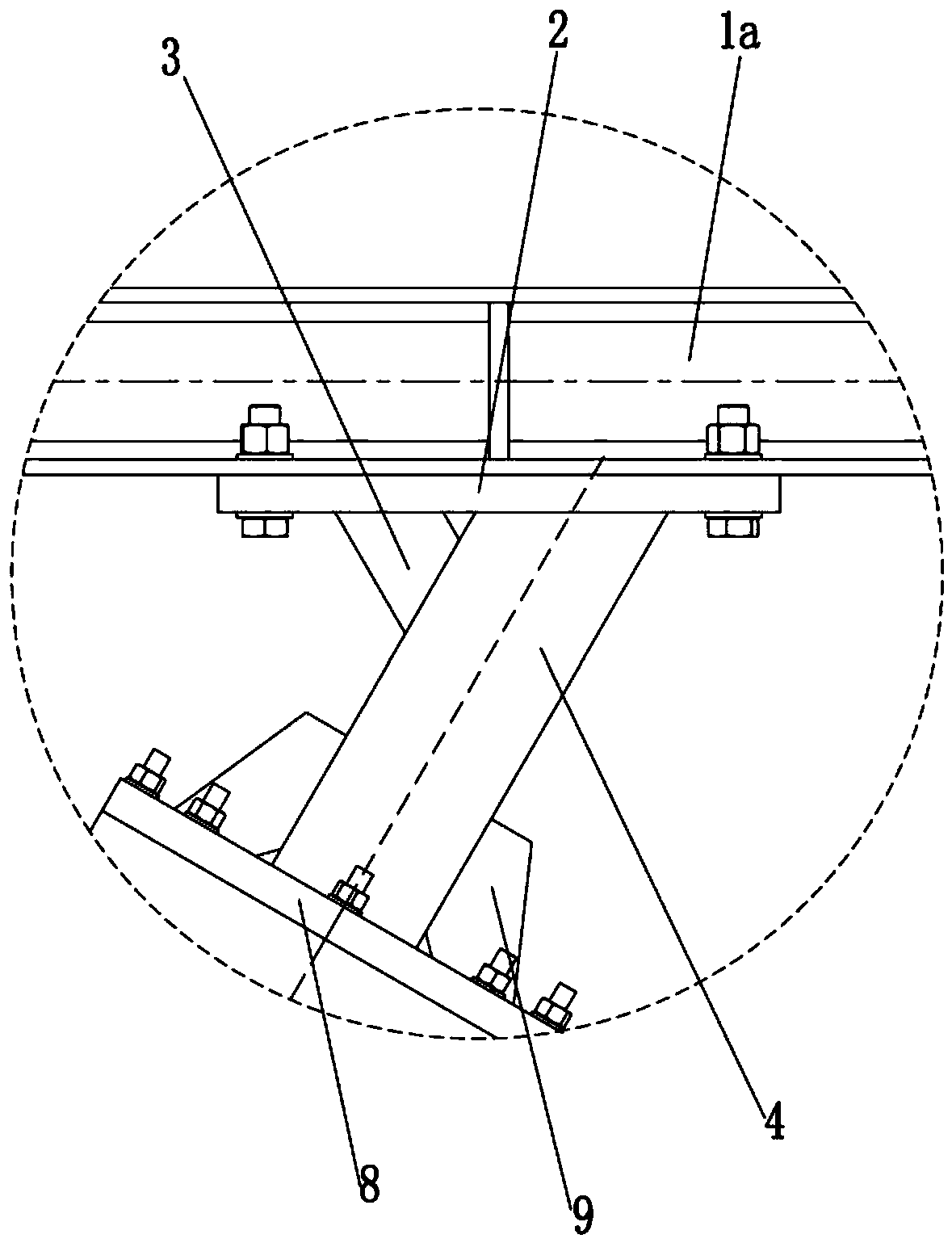

[0017] Such as Figure 1-2 As shown, an anti-turnover high-temperature corrosion medium delivery pipeline assembly includes a high-temperature corrosion medium valve 5, a pipe joint 6, a pair of horizontally extending medium delivery pipelines 7, and a pair of medium delivery pipelines 7 are inserted into the pipe joint 6 respectively. Both ends are connected with the pipe joint 6, and the high-temperature corrosive medium valve 5 is installed in conjunction with the pipe joint 6 to control the on-off state of the pipe joint 6, and the axis of the high-temperature corrosive medium valve 5 is inclined, and the high-temperature corrosive medium valve 5 is matched An anti-turnover fixed foundation is provided. The anti-turnover fixed foundation includes a door-shaped bracket 1, a top plate 2, a rib plate 3, and a central axis tube 4. The top plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com