Adjustable blade bamboo slicer

A slicer and bamboo technology, applied in mechanical equipment, sugarcane machining and other directions, can solve the problem of non-adjustable width of bamboo slices, and achieve the effects of low cost, reliable positioning and improved slice opening accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

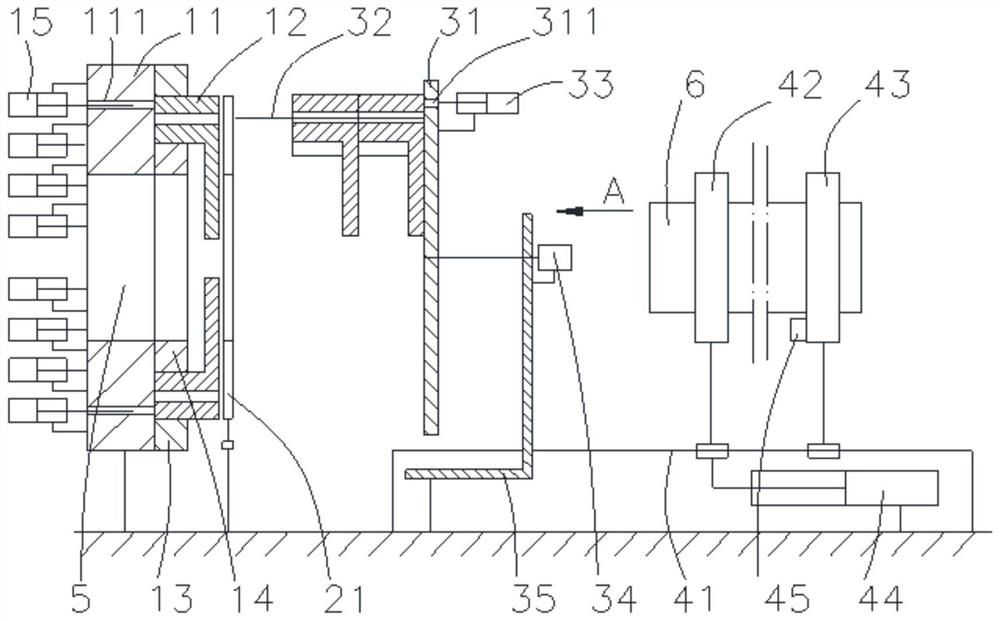

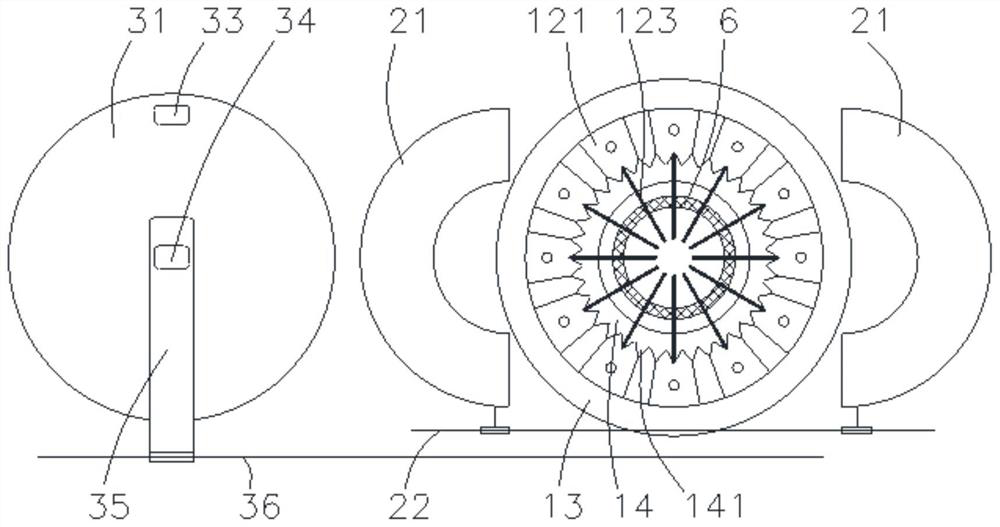

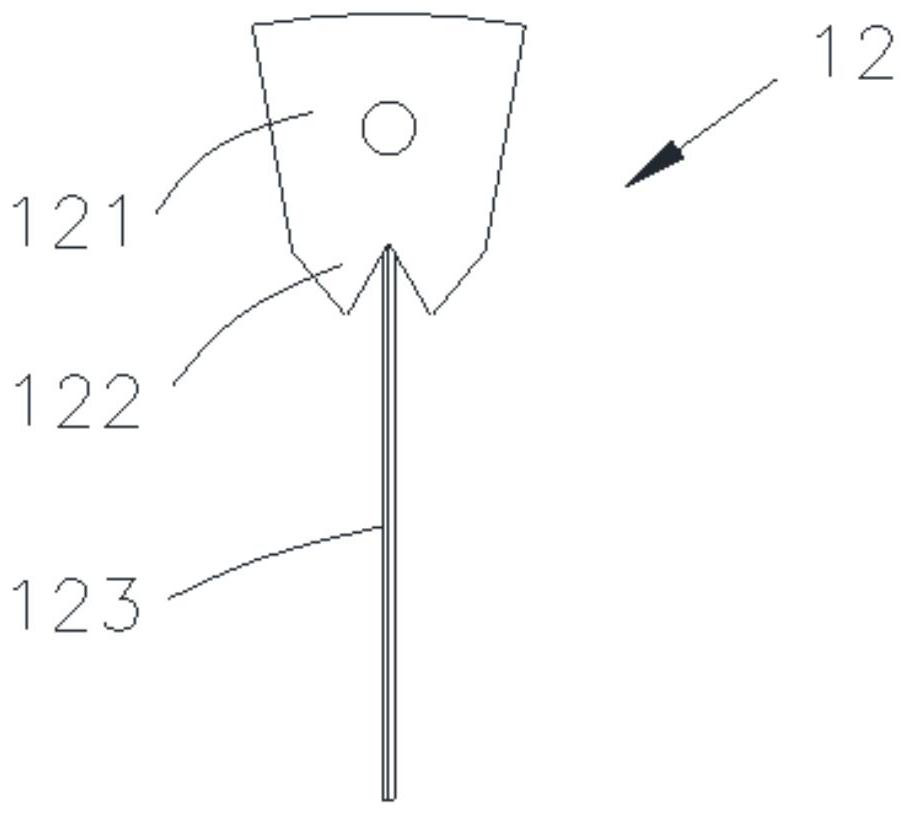

[0020] Such as Figure 1~4 As shown, a bamboo slicer with adjustable blades includes a knife-fixing mechanism, a knife-blocking mechanism, a knife-setting mechanism and a bamboo clamping mechanism arranged in sequence, and the knife-fixing mechanism includes a hollow base 11 and several knife assemblies 12. The knife assembly 12 includes a fixedly connected knife seat 121 and a blade 123. The base 11 is fixedly provided with an outer ring 13 and an inner ring 14. The outer peripheral surface of the inner ring 14 extends outwards to a certain extent. Position tooth 141, one end of the knife seat 121 fits with the arc inner wall of the outer ring 13, and the other end cooperates with the spacer tooth 141. One end of the positioning tooth 141 has several triangular teeth 122 that cooperate with the spacer teeth. The number of the triangular teeth on one tool holder 121 in this embodiment is two, and the two triangular teeth 122 are inserted into the corresponding position respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com