A combined internal combustion type low temperature and low NOx natural gas burner and combustion method

A combustion method and natural gas technology, applied in combustion methods, gas fuel burners, burners, etc., can solve the problems of high NOx emission and high combustion temperature, and achieve the effect of strengthening cooling effect, realizing NOx emission and low NOx emission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

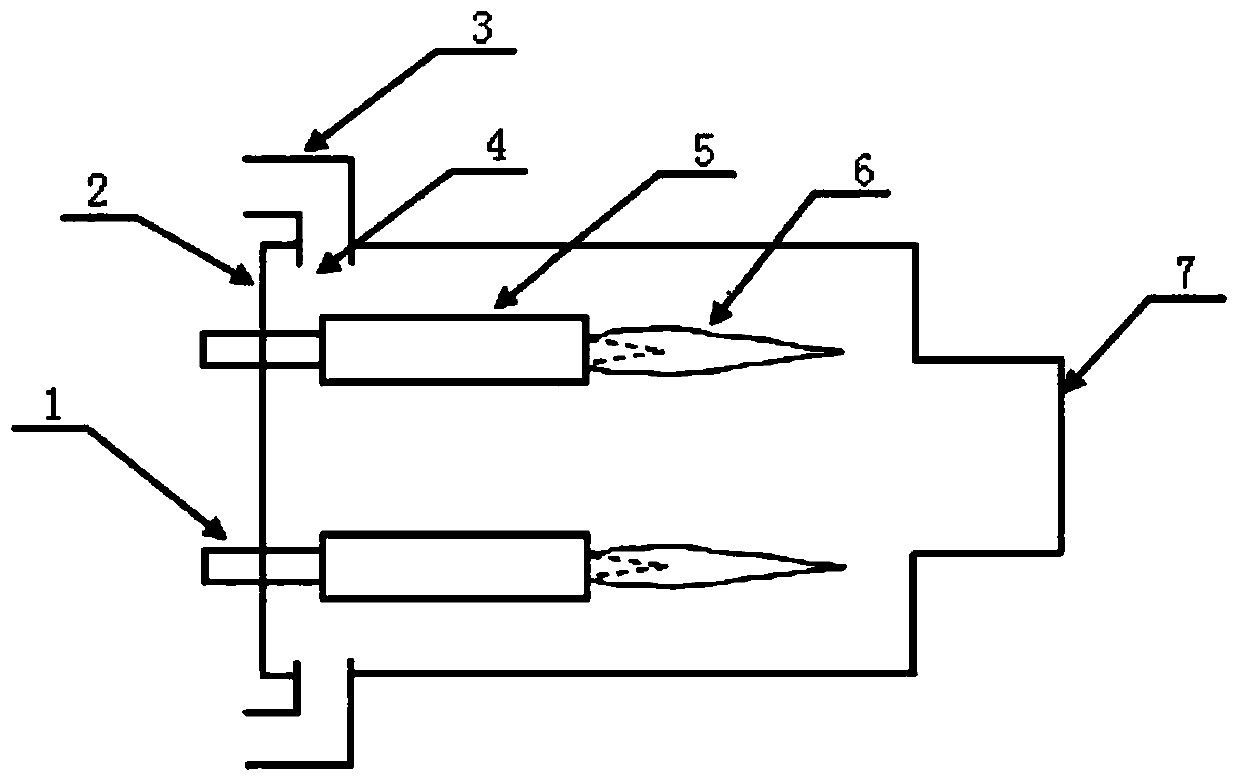

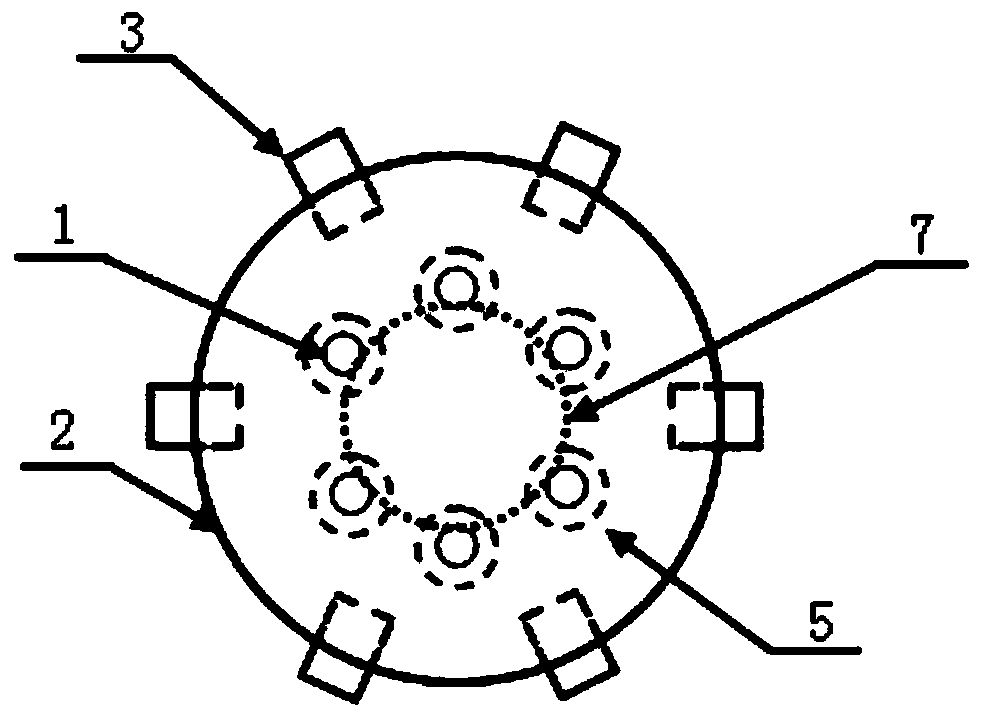

[0038]In this embodiment, the diameter of the cooling air inlet 4 is 0.3m, the number of cooling air inlets is 6, the outlet diameter of the sub-burner 1 is 0.05m, the number of the sub-burner 1 is 6, the flame collector 5 and the sub-burner The outlet of nozzle 1 is connected, and the connection is kept sealed; natural gas and air enter the flame collector 5 from the outlet of sub-burner 1, and burn while mixing; cooling air enters the internal combustion chamber 2 from the cooling air inlet 4, and cools the flame collector 5 and heated during this process; the incompletely burned natural gas flows out of the flame collector 5 and continues to burn to form an internal combustion flame 6, and the combustion product after the complete combustion of the natural gas is mixed with the cooling air heated by the flame collector to form a mixed gas from The combustion products are discharged from outlet 7 for use by energy-consuming equipment.

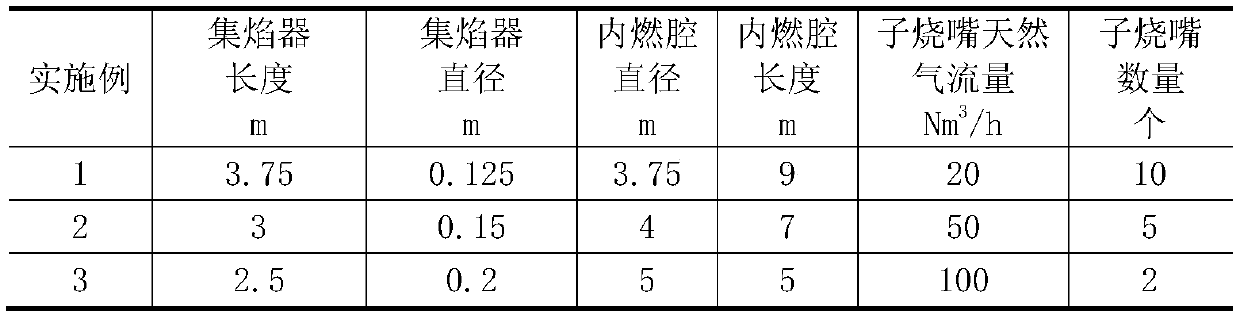

[0039] The relevant parameters of 3 ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com