Full-automatic firework grain pressing device

A fully automatic, powder-column technology, which is applied in pyrotechnics, offensive equipment, weapon types, etc., can solve the problems that the equipment cannot be operated unmanned on the production site, it is difficult to provide automatic device operation methods, and the drug application process is highly dangerous. The effect of personal injury accident, simple action and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

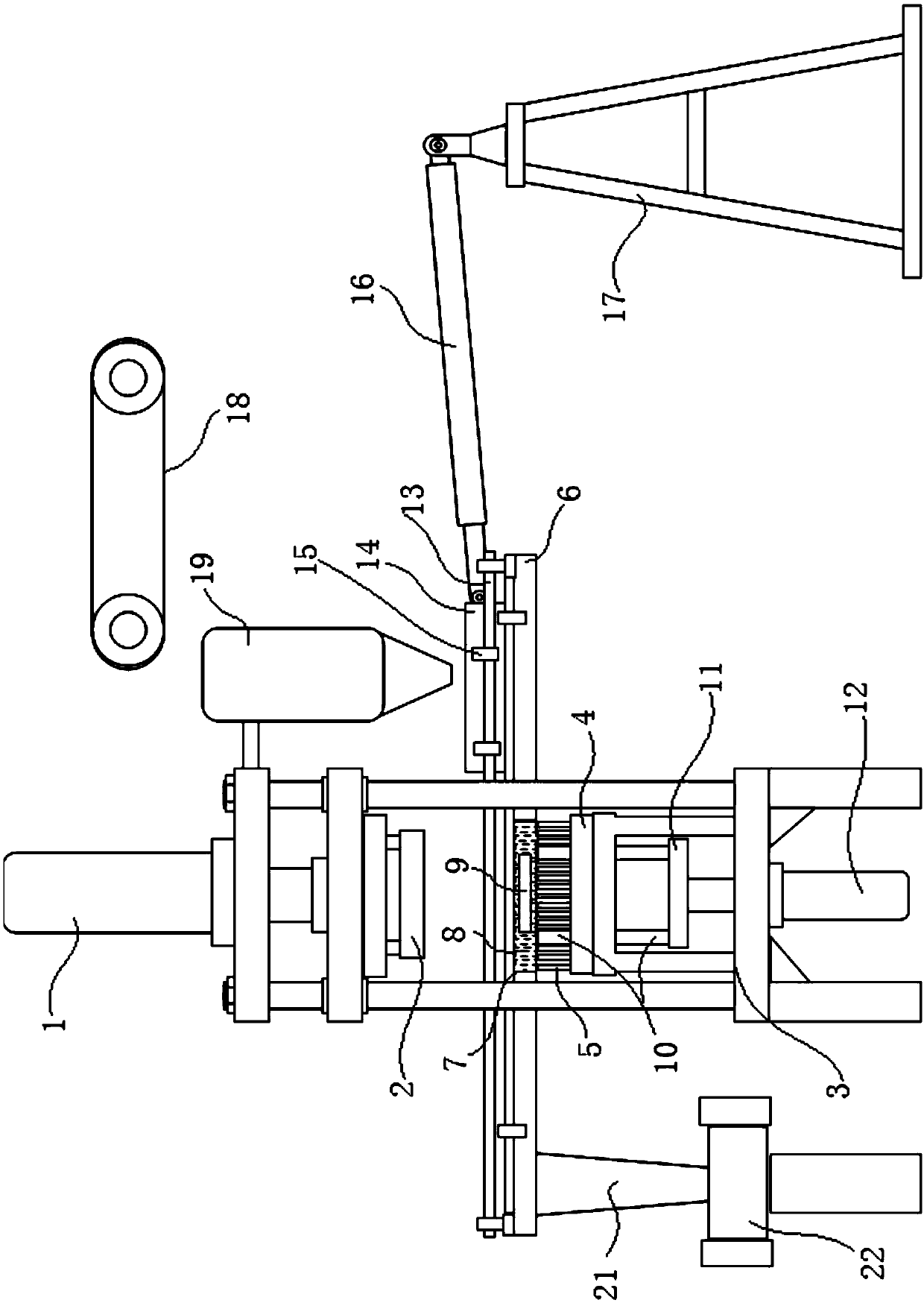

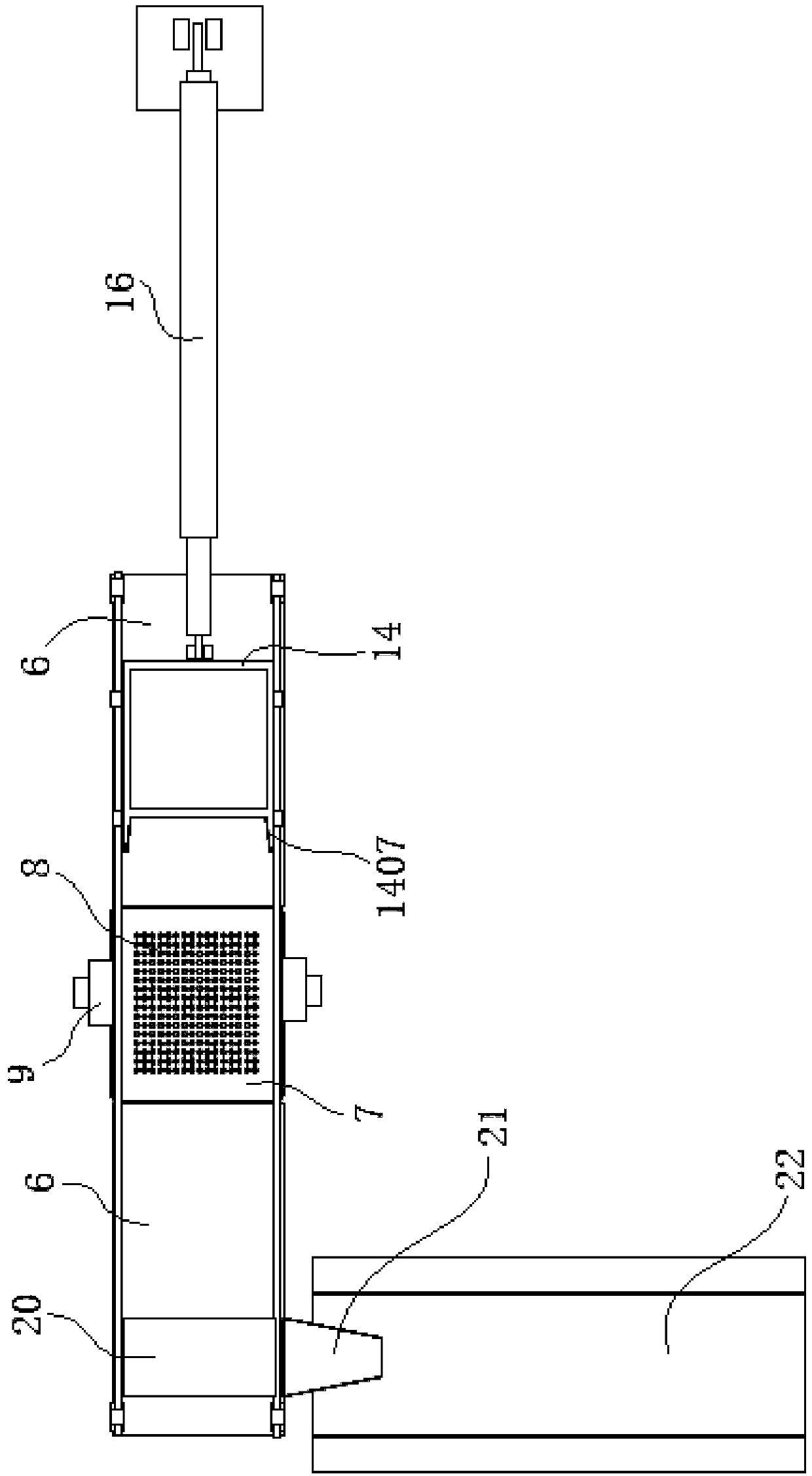

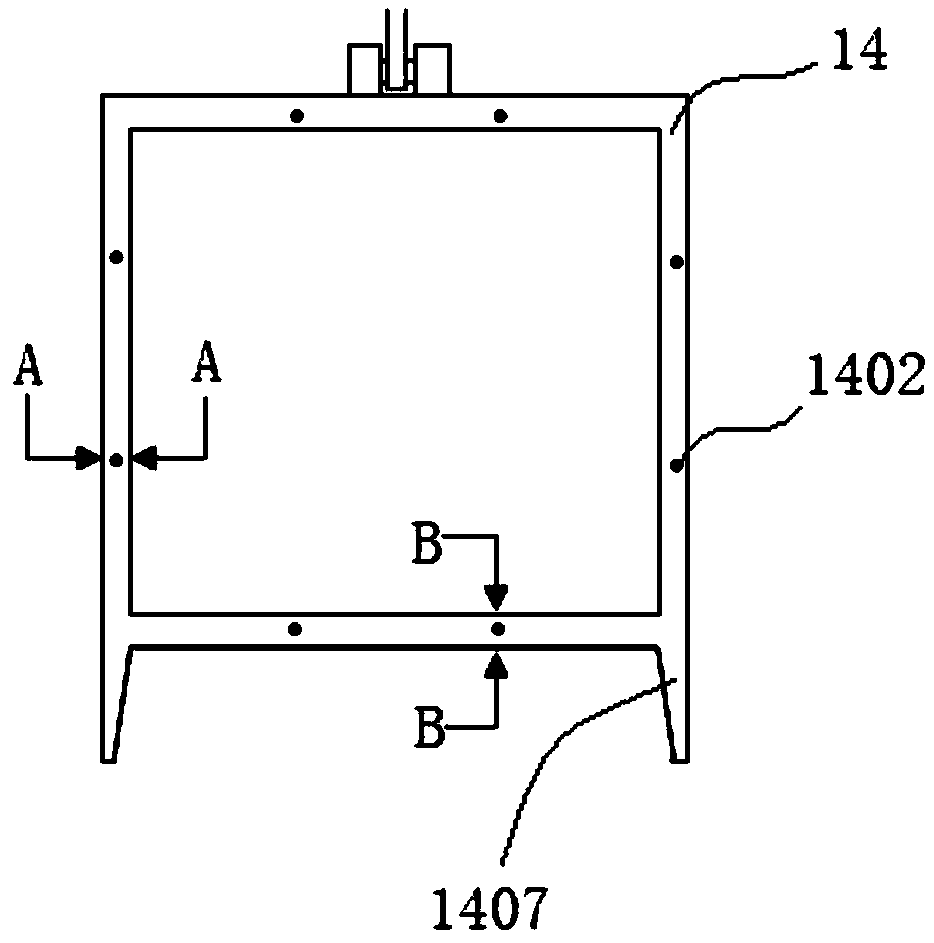

[0024] Referring to the accompanying drawings, which reflect a specific structure of the present invention, the fully automatic fireworks powder suppressing device includes a pressing plate 2 connected to the upper oil cylinder 1 of the hydraulic press; a base plate 4 fixed on the frame 3 is correspondingly provided under the pressing plate 2, and the base plate 4. Arranging several top pillars 5 in matrix.

[0025] A working panel 6 is installed between the pressing plate 2 and the base plate 4, and the middle part of the working panel 6 is detachably assembled with a charging plate 7, and a plurality of charging holes 8 are arranged in a matrix on the charging plate 7, and the charging plate 7 is provided with a vibrator 9, The upper jack column 5 is correspondingly nested in the charging hole 8, and the working panel 6 is connected to the lower oil cylinder 12 of the hydraulic press through the connecting rod 10 and the thrust plate 11 in sequence.

[0026] The working pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com