Punch safety device as well as punch and refitting method thereof

A safety device, punching technology, applied in safety equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as damage accidents and downward movement of sliders, and achieve the effects of reliable safety performance, improved safety, and low implementation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

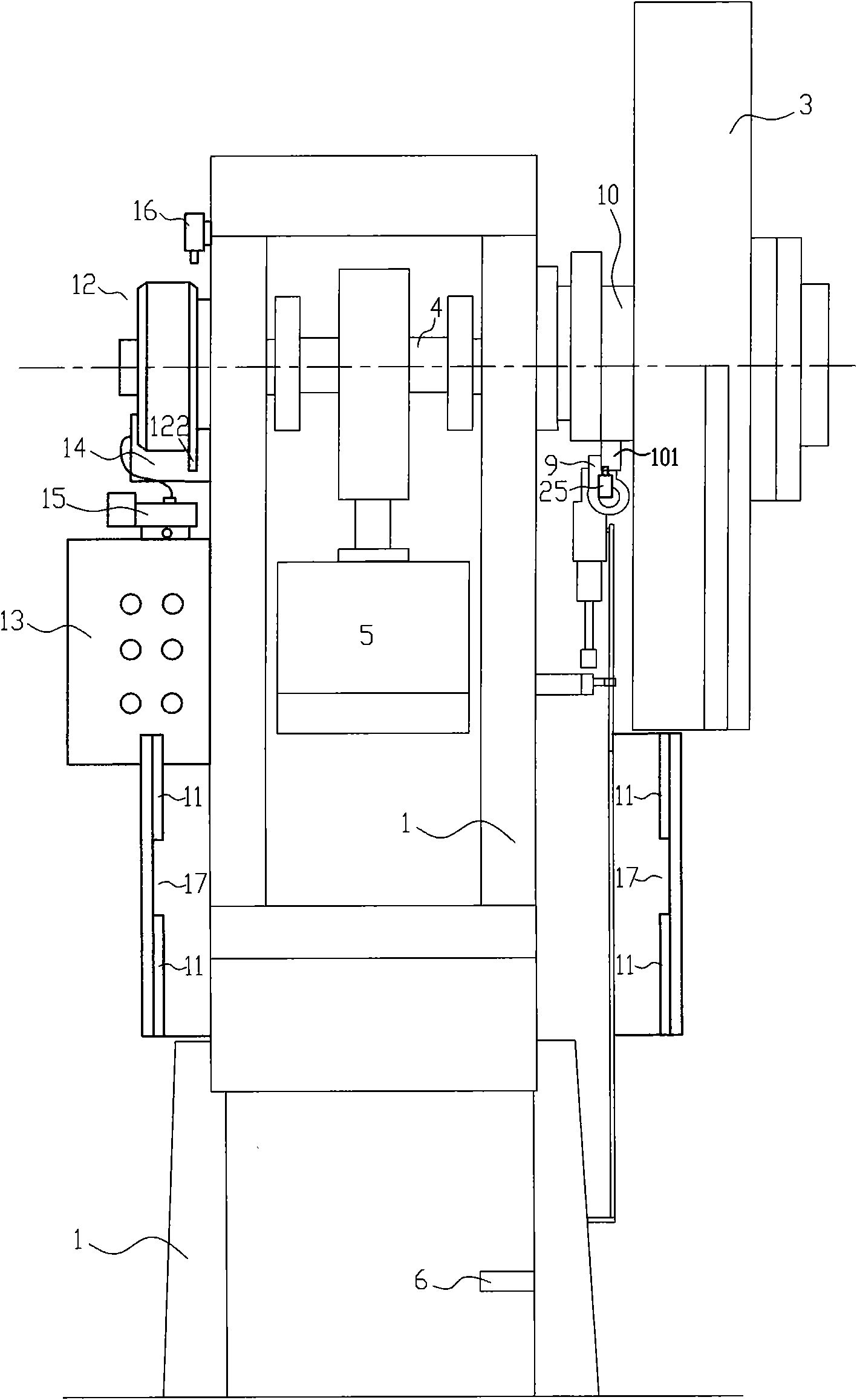

[0030] like Figure 1 to Figure 4 Shown, J23 series open tilting punch press, see as figure 1 , figure 2 The thin line part is shown. Including the frame 1, the motor 2 set on the rear upper part of the frame 1 drives the flywheel 3 through the belt, and the flywheel 3 is equipped with a clutch, which is vacantly sleeved on the crankshaft 4, and the clutch function is realized through the clutch of the movable key; J23 series open type The tiltable punching machine ensures that the clutch is in the disengaged state in the normal state through the following scheme: a runner 10 with a block 101 is placed on the crankshaft 4 close to the flywheel 3 and forms a linkage relationship with the clutch. When the runner 10 is blocked by another object, it will not When the clutch is in motion, the clutch cannot rotate and it is in a disengaged state; when the clutch is in a disengaged state, the flywheel 3 is in an idling state; once the other object is not blocked, the runner 10 wil...

Embodiment 2

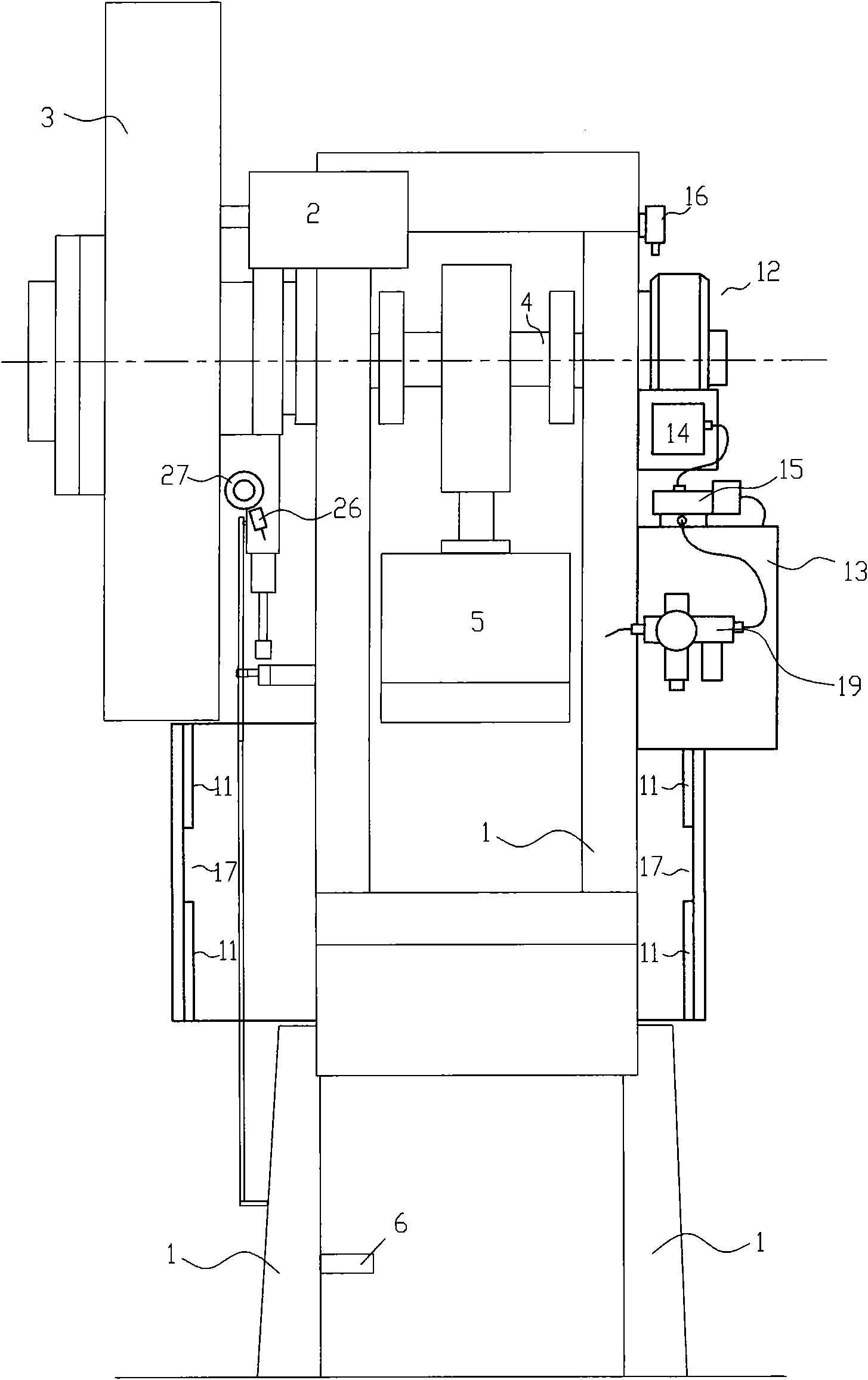

[0038] This embodiment is a further improvement on the basis of Embodiment 1. The button control method is used to replace the traditional pedal-operated start control method, that is, the button-operated mechanism is used to replace the pedal-operated mechanism to further improve the punching pressure. Process safety, while improving the ease of operation and automation of the punch press.

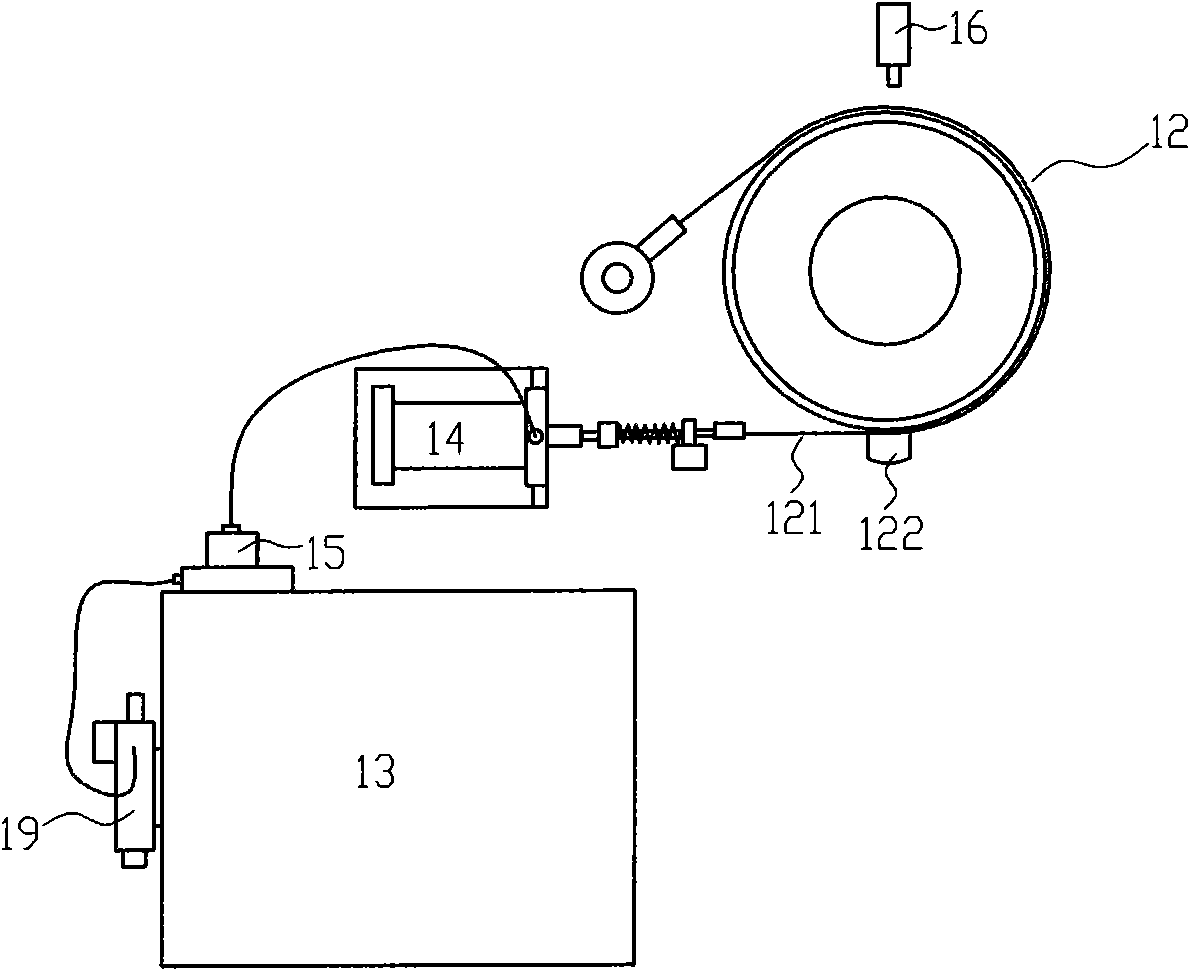

[0039] like Figure 5 to Figure 7 As shown, the thin line part also represents the domestic common J23 series open tilting punch presses (called presses) used by the safety device of the present invention. The safety device of the present invention can be found in Figure 1 to Figure 4 As shown in the thick line, it includes infrared light curtains 11 arranged on both sides of the front of the press console, a friction wheel brake device 12 arranged at the other coaxial end of the flywheel of the punch, and a matching device arranged at a suitable position around the punch or its surround...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com