High-temperature-resistant flexible long-gauge strain sensor and manufacturing method and application thereof

A technology of strain sensor and long gauge length, which is applied in engineering structure maintenance/monitoring and sensing fields, which can solve problems such as inability to withstand high temperatures, and achieve the effects of strong market competitiveness, security and property safety, and strong market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

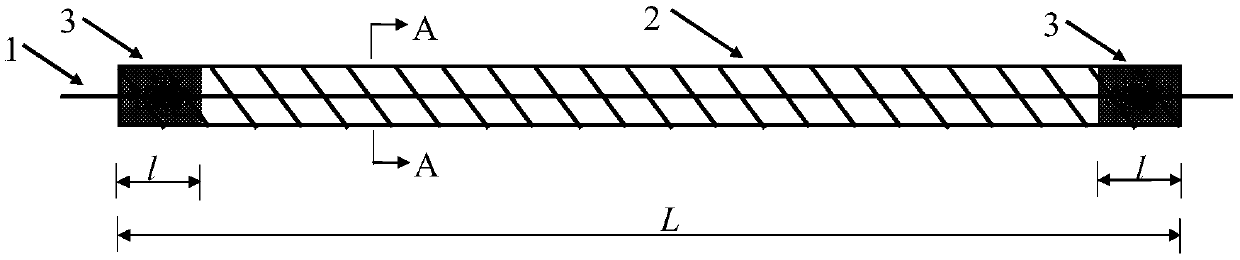

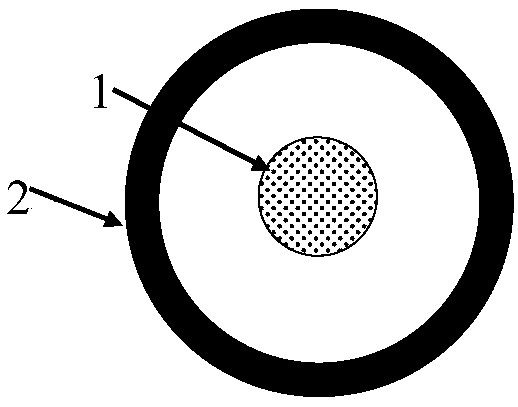

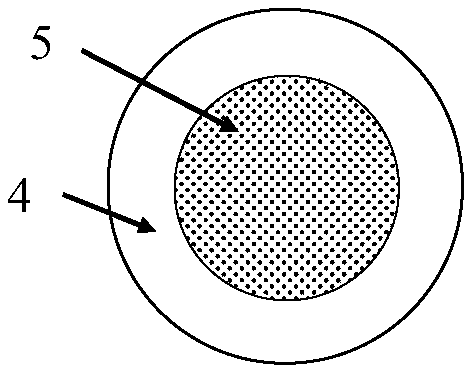

[0030] Such as Figure 1 to Figure 3 As shown, a high-temperature-resistant long-scale flexible strain sensor includes a packaging sheath 2 and a fiber grating 1 accommodated inside the packaging sheath. The fiber grating 1 is fixed in the packaging sheath 2 through the anchoring regions 3 at both ends, wherein the grating region of the fiber grating 1 is located between the two anchoring regions 3, so that the optical fiber (including the grating) between the two anchoring regions 3 The strain at each point on the grating area) is the same, so the strain monitored by the grating area can directly reflect the average strain within the length range between the two anchoring areas 3 . At the same time, the present invention uses steel springs as packaging materials, which have a certain rigidity in the circumferential direction, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com