Forming method of semiconductor device and semiconductor device

A technology for semiconductors and devices, applied in the field of semiconductors, can solve problems such as breakdown over time, no reduction in capacitance, reliability risks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

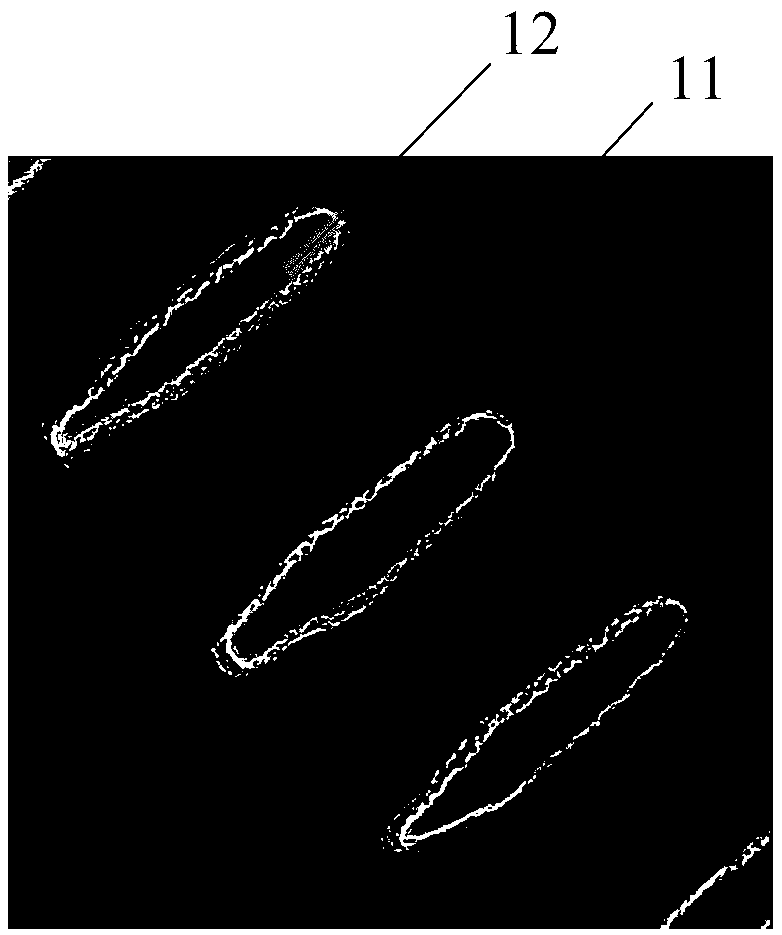

Image

Examples

Embodiment 1

[0069] Based on the above-mentioned problems in the related art, the present embodiment provides a method for forming a semiconductor device. The method for forming a semiconductor device can facilitate the pinch-off of the air gap at the top by forming the first metal line with inclined sidewalls. An effective air gap is formed, thereby improving the RC delay of the semiconductor device.

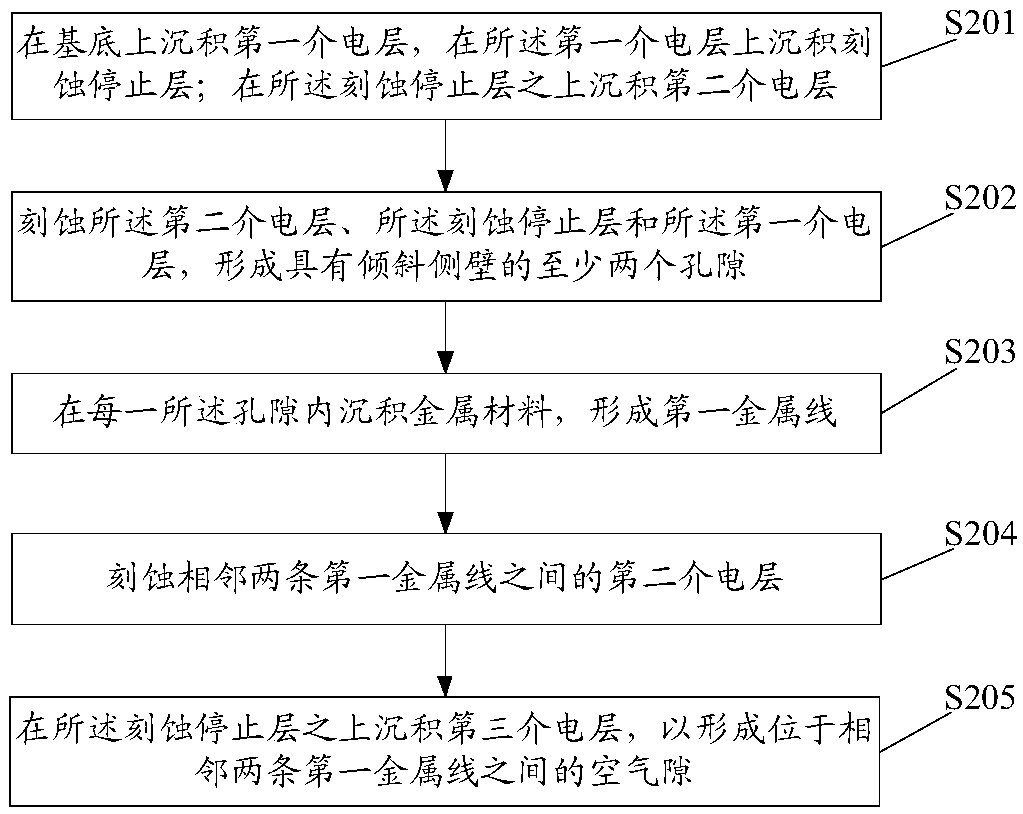

[0070] figure 2 It is a schematic diagram of the implementation flow of the method for forming a semiconductor device provided in the embodiment of the present application, as shown in figure 2 As shown, the method includes the following steps:

[0071] Step S201 , depositing a first dielectric layer on the substrate, depositing an etching stop layer on the first dielectric layer; depositing a second dielectric layer on the etching stop layer.

[0072] Such as Figure 3A As shown, a first dielectric layer 31 is deposited on a substrate 30, an etch stop layer 32 is deposited on the firs...

Embodiment 2

[0101] This embodiment provides a method for forming a semiconductor device. By forming a first metal line with an inclined sidewall, the method for forming a semiconductor device can facilitate the pinching of the air gap at the top to form an effective air gap, thereby improving the semiconductor performance. RC delay of the device.

[0102] Figure 4 It is a schematic diagram of the implementation flow of the method for forming a semiconductor device provided in the embodiment of the present application, as shown in Figure 4 As shown, the method includes the following steps:

[0103] Step S401, providing a substrate, and depositing a first dielectric layer on the substrate.

[0104] Such as Figure 5A As shown, a first dielectric layer 52 is deposited on a substrate 51, and there are at least two second metal lines 521 in the first dielectric layer 52, and the extending direction of each second metal line 521 is perpendicular to the The first dielectric layer 52 .

[...

Embodiment 3

[0153] An embodiment of the present application provides a semiconductor device. In this embodiment, the semiconductor device may be a NAND flash memory.

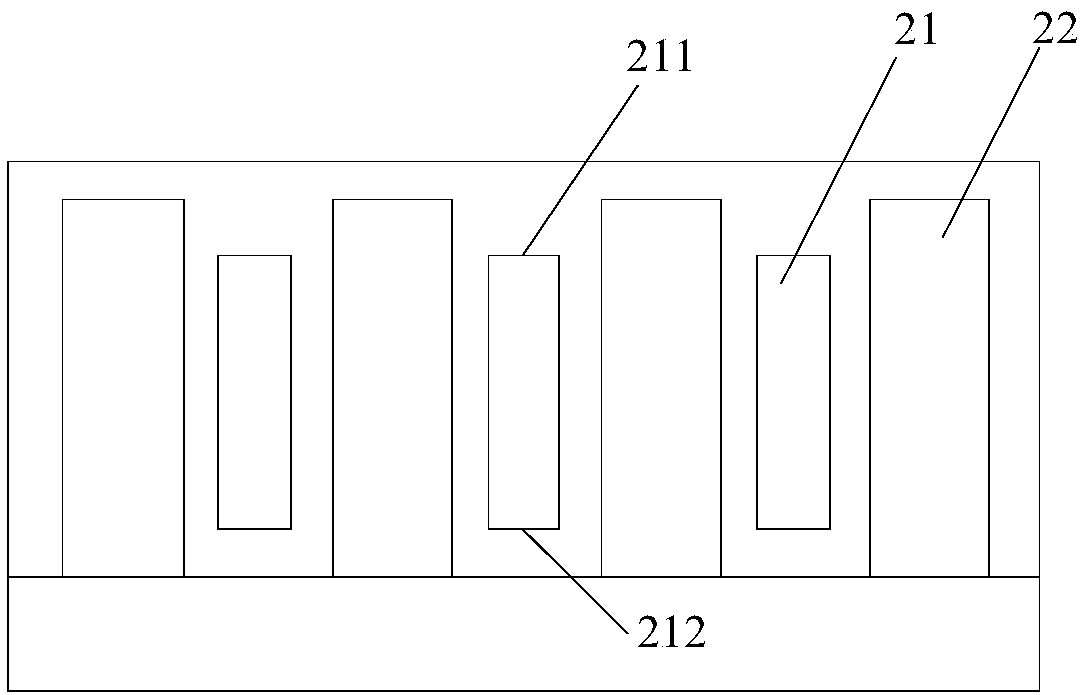

[0154] Figure 6 A schematic structural diagram of a semiconductor device provided in the embodiment of the present application, such as Figure 6 As shown, the semiconductor device includes:

[0155] base 60;

[0156] a first dielectric layer 61 on the substrate;

[0157] an etch stop layer 62 over the first dielectric layer;

[0158] at least two apertures 611 with sloped sidewalls;

[0159] a first metal line 612 located within each of said apertures;

[0160] a third dielectric layer 63 deposited over the etch stop layer;

[0161] The air gap 613 is located between two adjacent first metal lines.

[0162] Here, the substrate 60 is located at the bottom of the entire semiconductor device, and the material of the substrate 60 can be selected from one of Si, SiGe, SiC, Al2O3, AlN, ZnO, Ga2O3, LiAlO2 and the like. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com