Barrier layer for interconnection structure and preparation method thereof

A technology of interconnection structure and barrier layer, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of unsatisfactory barrier layer effect, etc., to improve poor performance, improve RC delay, and reduce heat Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

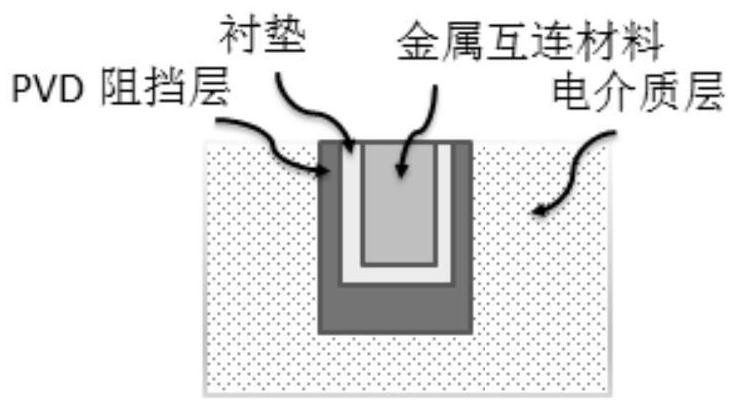

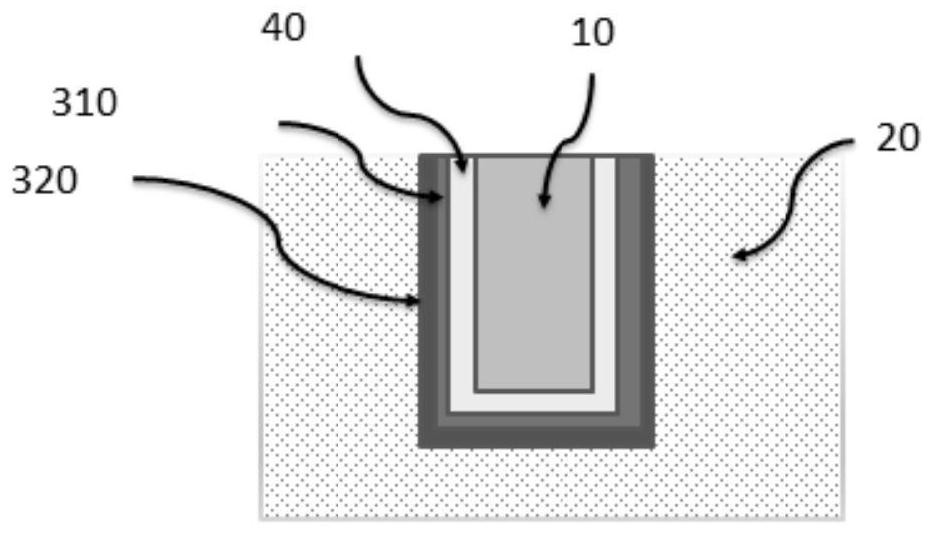

[0026] In order to solve the foregoing technical problems, the present invention provides a barrier layer for an interconnection structure, which is disposed between the metal interconnection material 10 and the dielectric layer 20 of the interconnection structure, and the barrier layer includes a first barrier layer 310 and a second barrier layer 320 , the first barrier layer 310 surrounds the outer layer of the metal interconnection material 10 , and the second barrier layer 320 surrounds the first barrier layer 310 outside. Wherein, the first barrier layer and the second barrier layer are formed by atomic layer deposition.

[0027] Specifically, in an embodiment of the present invention, the materials of the first barrier layer and the second barrier layer are different. The first barrier layer is made of a material with stable metal properties and good adhesion, so as to improve the adhesion between the second barrier layer and the metal interconnection material. Further,...

Embodiment 2

[0030] Such as figure 1 As shown, the present invention provides an interconnection structure comprising a metal interconnection material 10 , a dielectric layer 20 , a barrier layer and a liner 40 . Wherein, the liner 40 is disposed outside the metal interconnection material 10 , and the barrier layer is disposed between the liner 40 and the dielectric layer 10 . The barrier layer includes a first barrier layer 310 disposed on the outer layer of the liner 40 and a second barrier layer 320 disposed outside the first barrier layer. Wherein, the metal interconnection material is Cu.

Embodiment 3

[0032] The present invention provides a method for preparing a barrier layer for an interconnect structure, comprising the steps of:

[0033] depositing a first barrier layer outside the metal interconnect material of the interconnect structure;

[0034] A second barrier layer is deposited outside the first barrier layer.

[0035] Specifically, in an embodiment of the present invention, the first barrier layer and the second barrier layer are formed by atomic layer deposition. Since the two barrier layers are deposited by atomic layer deposition, the two barrier layers can be formed at the same temperature through one ALD chamber, thereby improving production efficiency.

[0036] The present invention also provides an electronic device comprising an interconnection structure manufactured according to the method of an exemplary embodiment of the present invention. The electronic device can be any electronic product or equipment such as a mobile phone, a tablet computer, a not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com