Method for fabricating interconnection structure

A technology of interconnect structure and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve the problems of semiconductor substrate stress mismatch, trench disconnection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

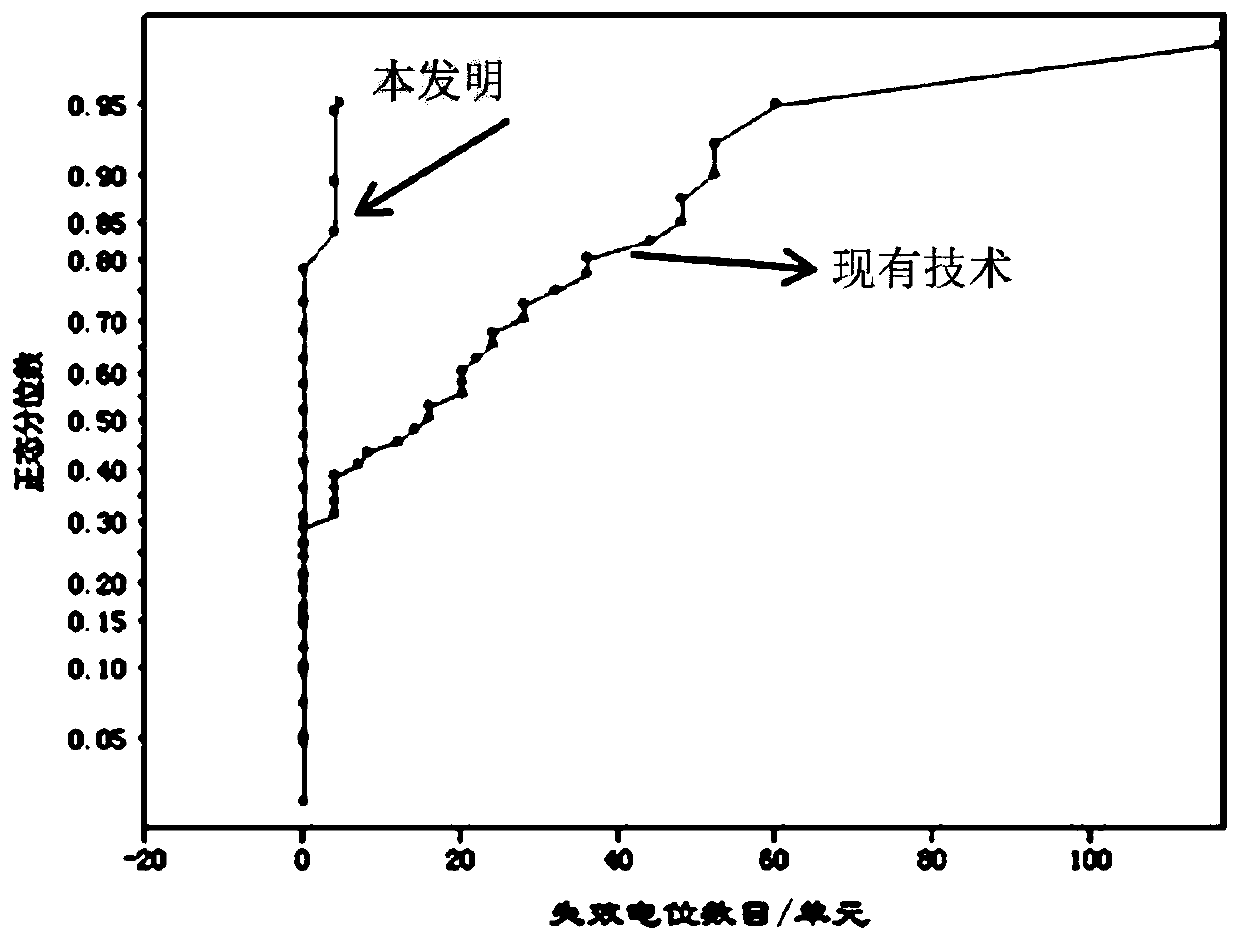

[0029] The core idea of the present invention is to provide a manufacturing method of an interconnect structure, which has no new process and can change the growth rate of copper grains without affecting the production capacity of the factory, so as to solve the problem of semiconductor lining in the prior art. The problem of trench disconnection caused by the mismatch of bottom stress improves product yield and process reliability.

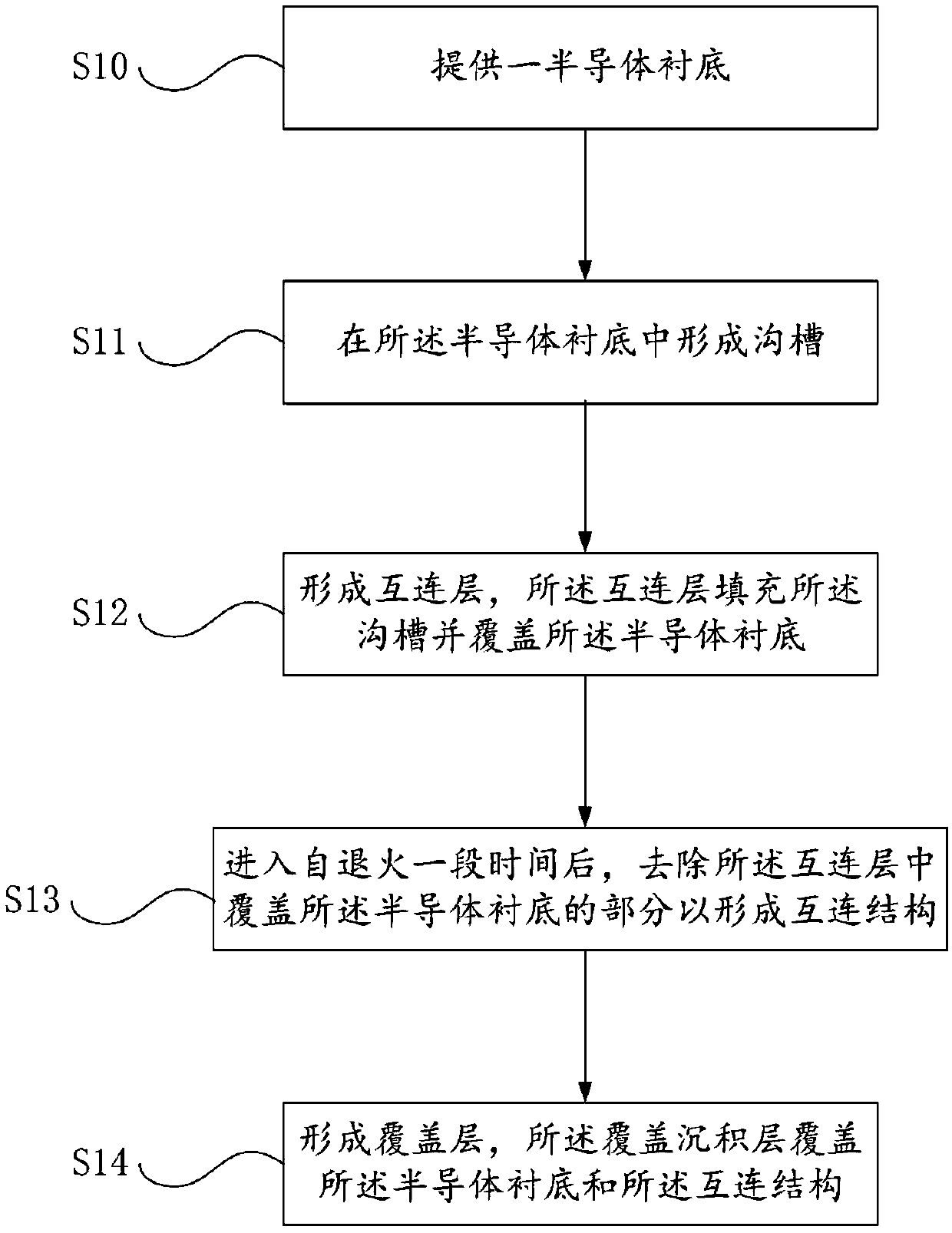

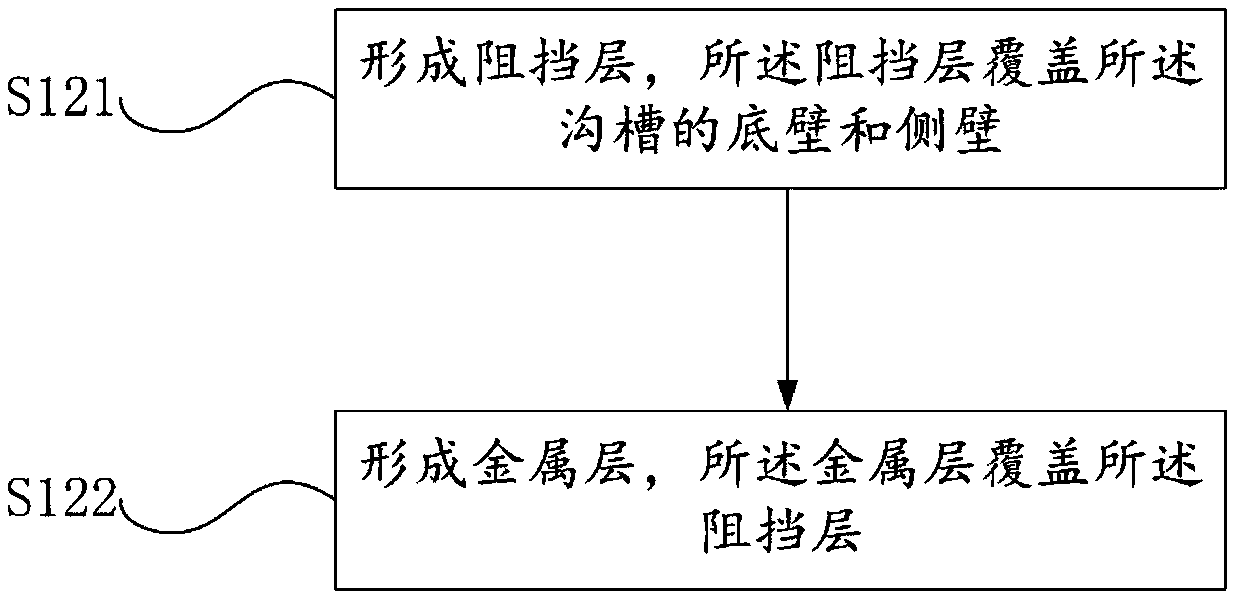

[0030] In order to realize the above-mentioned idea, the present invention provides a manufacturing method of an interconnect structure, the manufacturing method of the interconnect structure includes: providing a semiconductor substrate; forming a trench in the semiconductor substrate; forming an interconnect layer, so that the The interconnection layer fills the trenches and covers the semiconductor substrate; after entering the self-annealing period for a period of time, the part of the interconnection layer covering the semiconductor substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Section width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com