Vented type stopper with temperature measuring function

A technology of air-permeable stopper and temperature measurement function, which is applied in the configuration of indicating equipment/measuring equipment, manufacturing tools, casting molten material containers, etc., and can solve the problem of lagging temperature measurement response, difficulty in meeting process control requirements, and difficulty in preventing clogging clamps Slag removal and other issues to achieve the effect of promoting the floating of inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

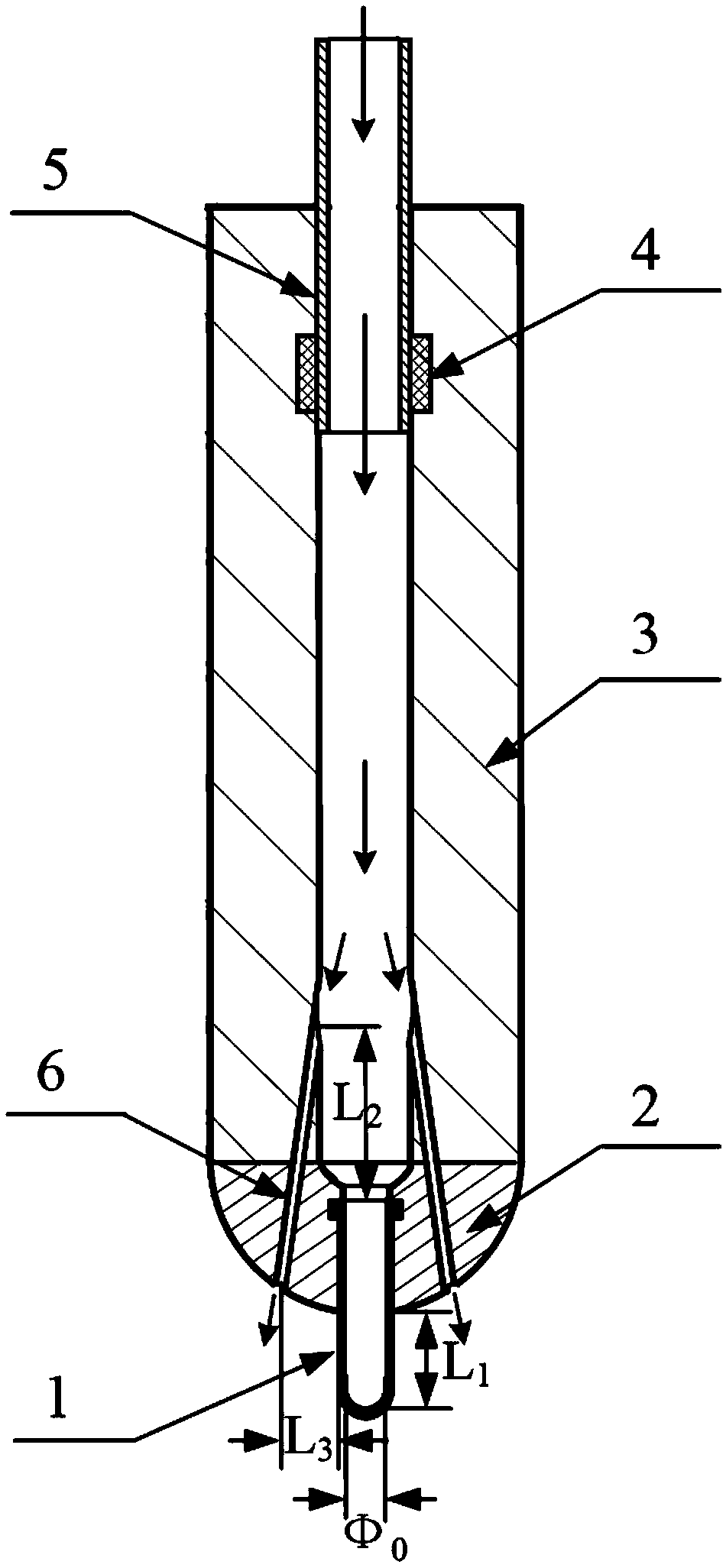

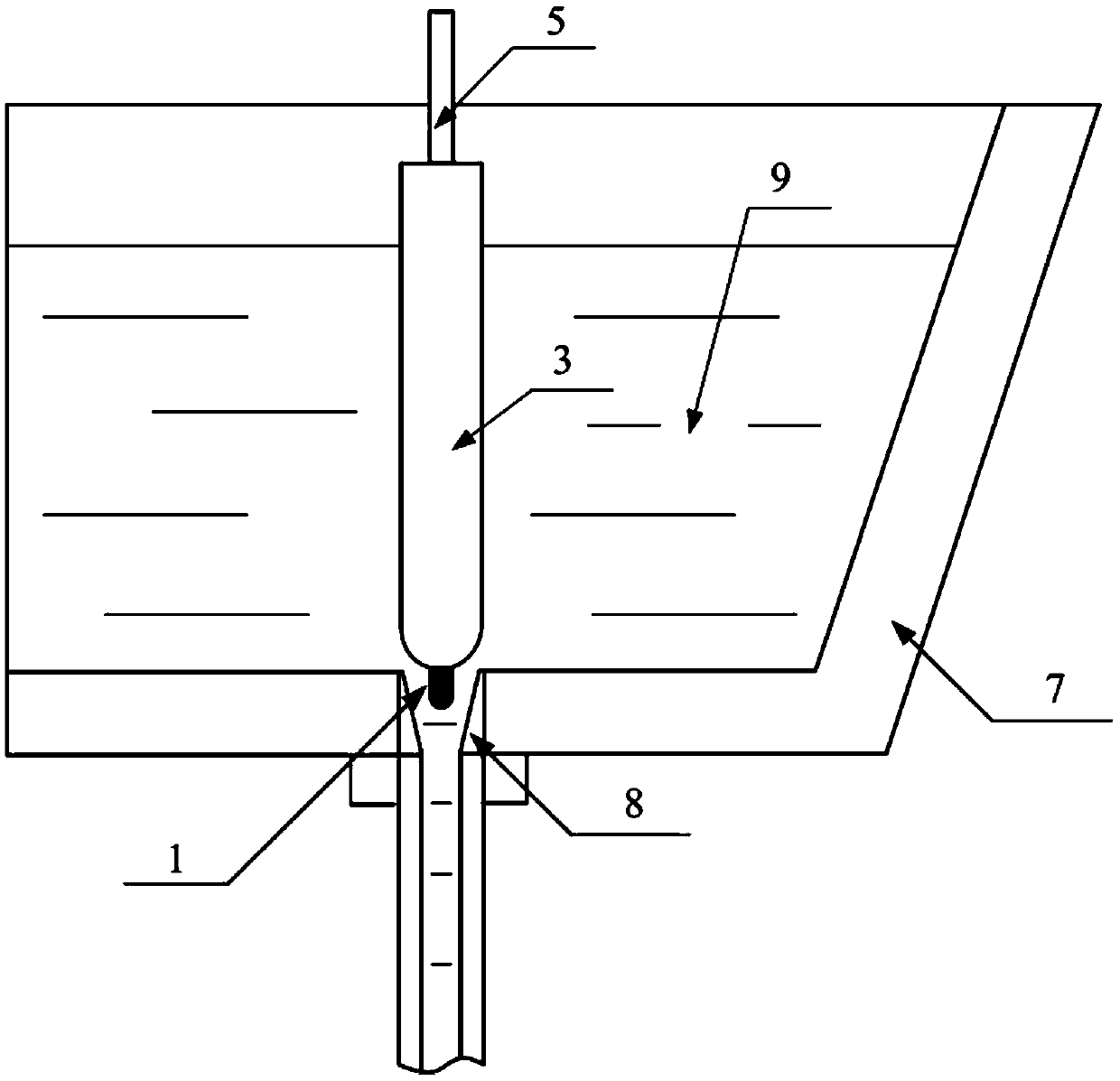

[0027] The present invention is a breathable stopper rod with temperature measuring function, such as figure 1 shown. The stopper rod includes a rod body 3, a rod head 2, a temperature measuring unit 1, a connecting pipe 5 and an exhaust passage 6; It is fixedly connected with the rod body, and the lower end of the rod body 3 is connected with the rod head 2; the temperature measuring unit 1 is a tubular structure with one end closed and the other end open, and the open end of the temperature measuring unit 1 is connected with the rod head 2 and connected with the rod head 2. The inner cavity of the rod body is connected, and the closed end of the temperature measuring unit 1 protrudes from the lower end of the rod head and exposes the rod ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com