Direct air-cooled condenser temperature online monitoring system and method

An air-cooled condenser and monitoring system technology, which is applied to steam/steam condensers, thermometers and thermometers using electrical/magnetic components directly sensitive to heat, etc., can solve the problem of high cable wiring space requirements and installation and maintenance costs. High, lack of flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0036] "Temperature sensor" refers to a sensor that senses temperature and converts it into a usable output signal. The temperature sensor is the core part of the temperature measuring instrument, and there are many varieties. According to the measurement method, it can be divided into two categories: contact type and non-contact type. The non-contact temperature sensor does not need to be in contact with the measured medium, but passes the heat radiation or convection of the measured medium to the temperature sensor to achieve the purpose of temperature measurement. This type of sensor mainly includes infrared thermometers. The environmental conditions in which the infrared thermometer is located, such as temperature, dust, smoke and steam conditions, have an impact on the selected specifications and measurement accuracy.

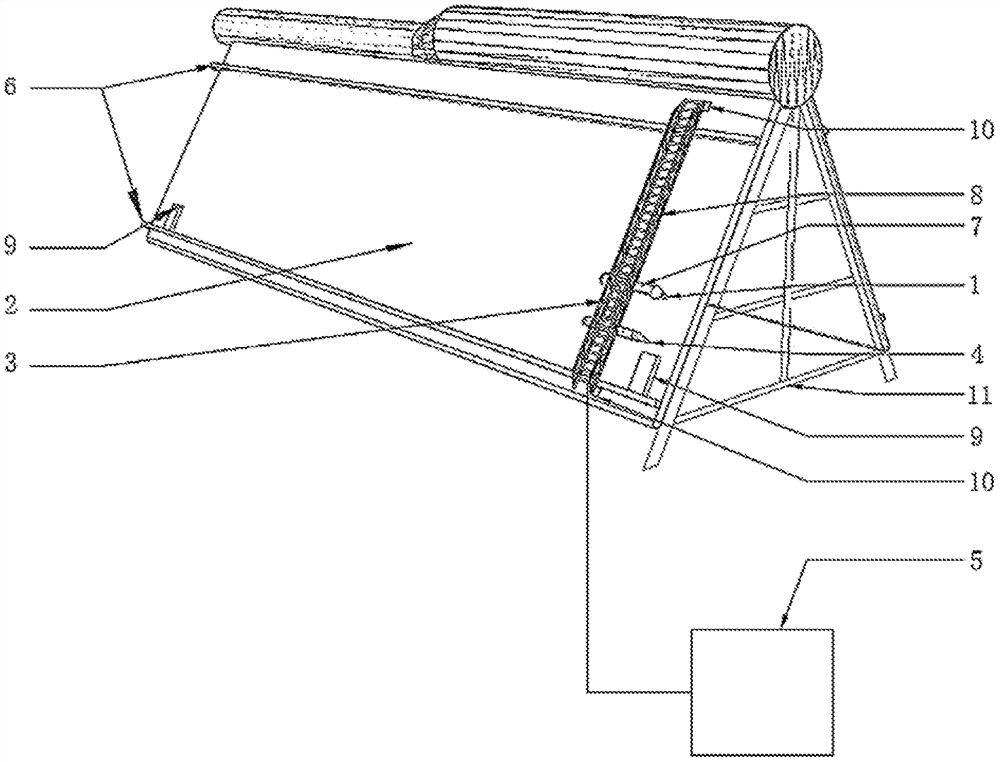

[0037] "Temperature sensor moving system" refers to a system that is installed above the surface of the heat exchange tube bank of the direct air-cooled...

Embodiment 1

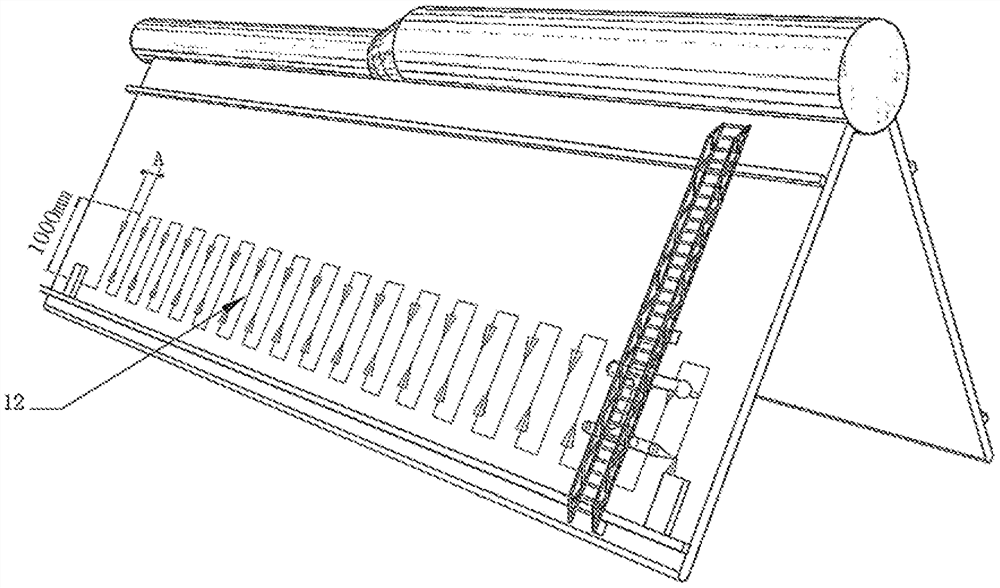

[0049] figure 2 It is the route that the temperature sensor mobile system moves and the area scanned by the temperature sensor that is preset by the four-row tube (MASH) system. During the start-up process of the equipment and when the load is low, in order to shorten the scanning period, the area can be limited to the plane area where the bottom of the heat exchange tube bundle traverses the entire tube bundle plane and moves up and down at a height of 1 meter, because the air flow passing through this area is large and brings The more heat it takes, the more likely it is to freeze. The scanning area and path are shown in 12, where the distance between the substrate tubes is A.

[0050] In the programmable controller system, buttons and travel switches are used as input signal elements of the programmable controller, and contactors are used as output actuators to control the horizontal drive mechanism for horizontal movement and the lifting drive mechanism for vertical move...

Embodiment 2

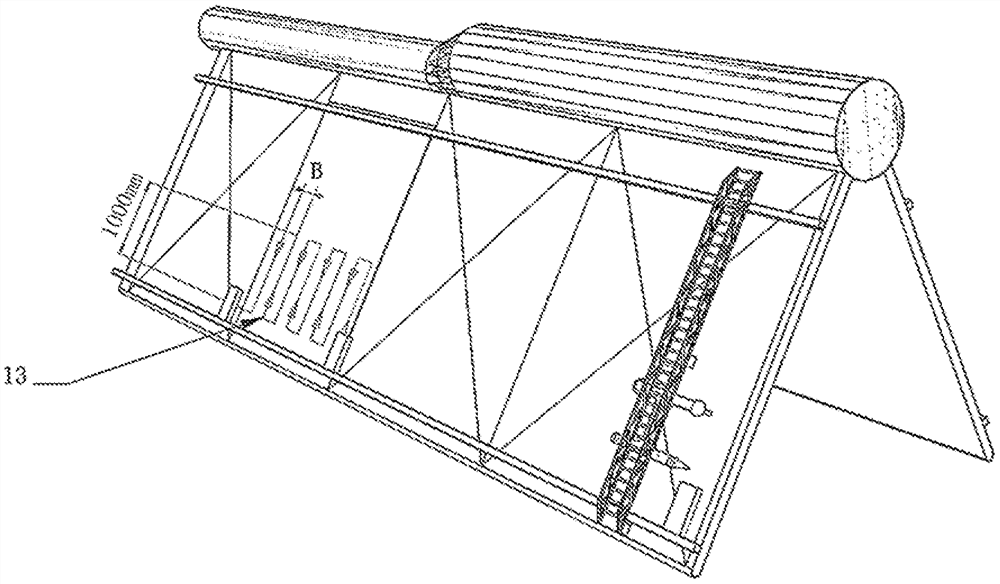

[0053] image 3 It is the route that the temperature sensor moving system moves and the area that the temperature sensor scans in advance for the single-pipe, double-pipe or triple-pipe system. Because for the single-row tube, double-row tube and three-row tube systems, the counterflow tubes are arranged separately in part of the heat exchange tube bundle area, and only the area where the counterflow tube bundle is separately arranged can be scanned. During the start-up of the equipment and when the load is low, in order to shorten the scanning period, it can be limited to a plane area with a height of 1 meter moving up and down along the bottom of the countercurrent tube bundle. The scanning area and path are shown in 13, where the distance between the substrate tubes is B.

[0054] When the automatic control operation starts, adjust the position of the mobile cleaning platform so that the temperature sensor is directly above the center line of the rightmost substrate tube, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com