A coal pile temperature measuring robot

A technology of robots and crawling robots, which is applied in the field of temperature measurement of coal piles, can solve the problems of inconvenient measurement of temperature defects, etc., and achieve the effect of simple and compact overall structure, ensuring normal operation and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

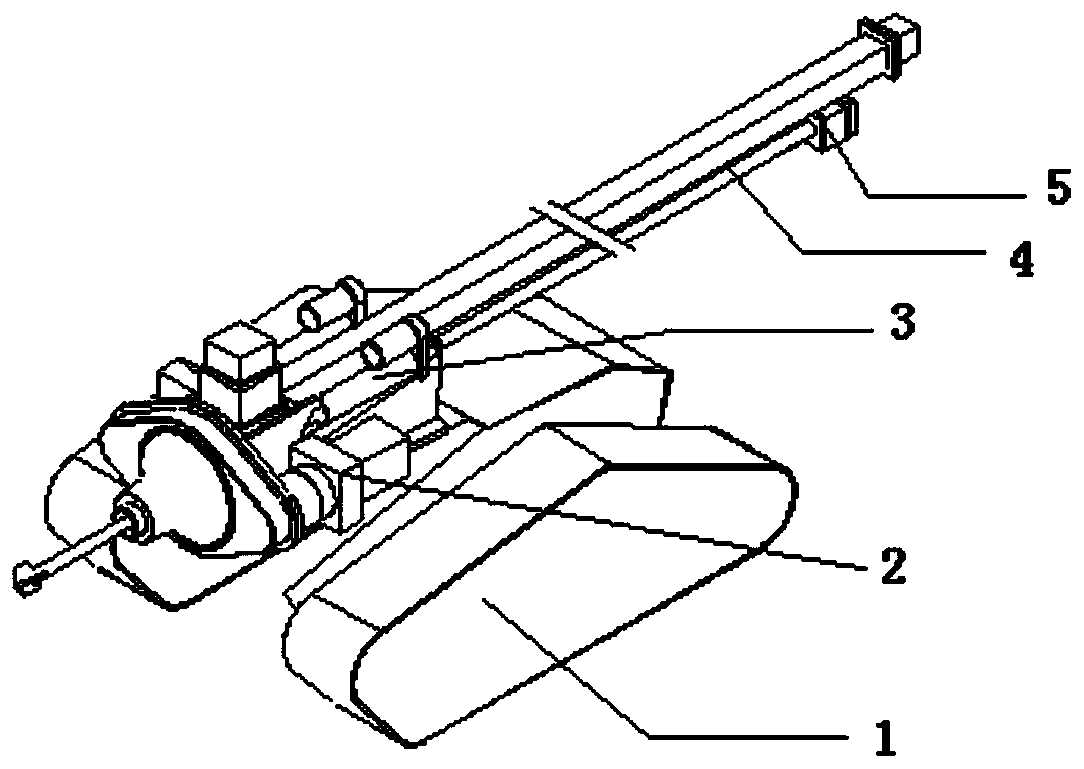

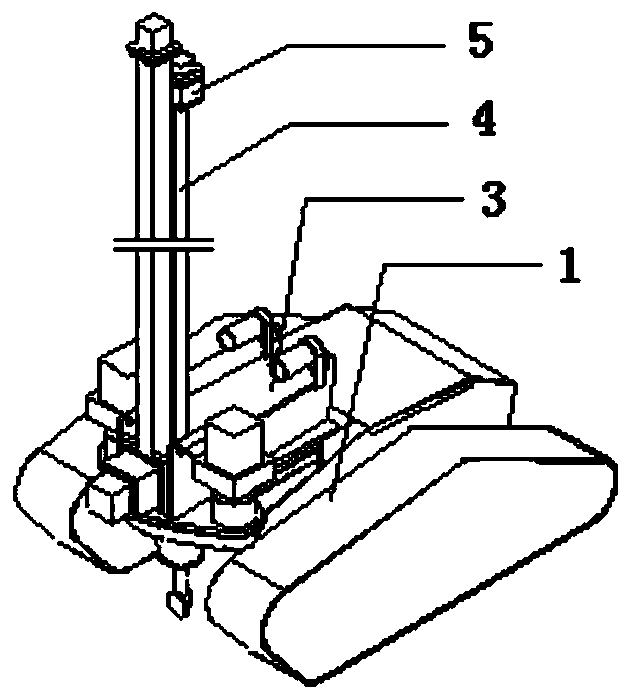

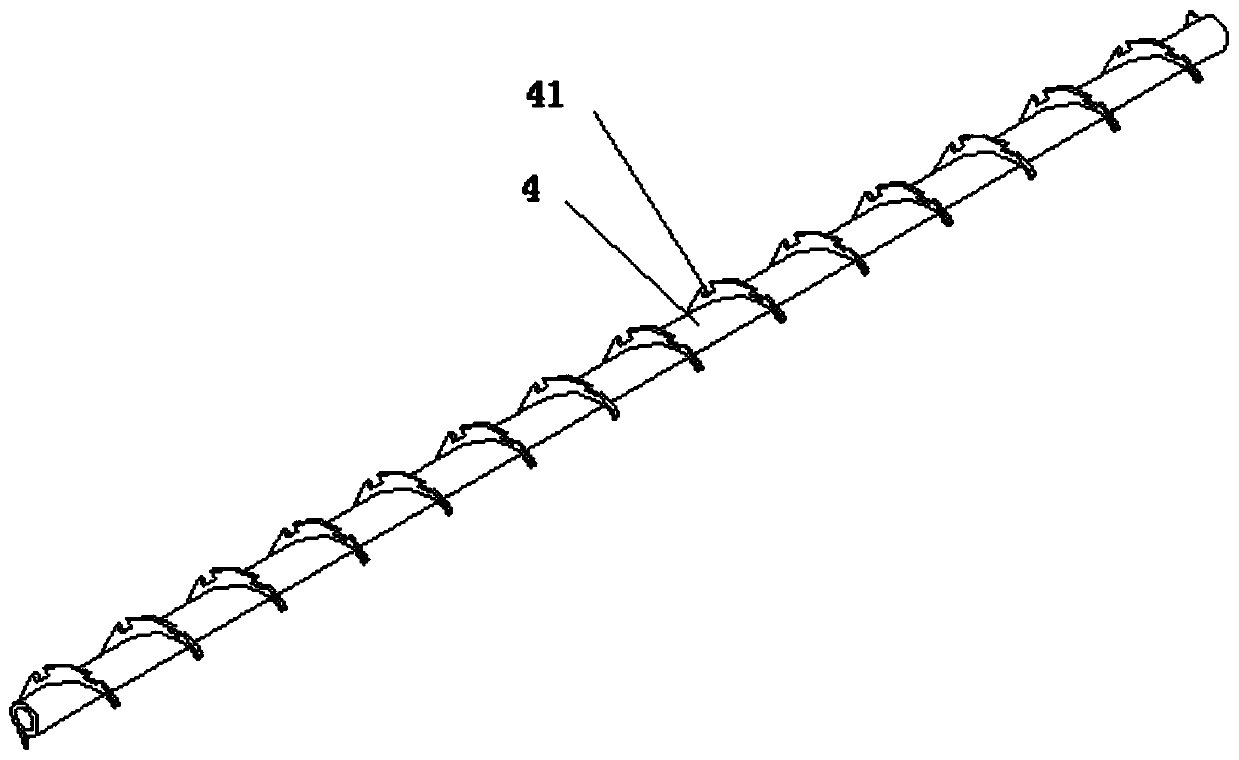

[0066] Such as Figure 1-5 Shown is a specific implementation of a coal pile temperature measuring robot, including a crawler robot 1, crawler robot 1 has crawlers, and can crawl to any position on the coal pile; Bracket 31, the pitch drive device drives the rotating bracket 31 to rotate. In this embodiment, the pitch drive device includes a number of retractable electric push rods, one end of the electric push rod is fixedly connected to the crawling robot 1, The other end is fixedly connected with the rotating bracket 31, and the rotating bracket 31 and the pitch driving device constitute the pitching mechanism 3, and the screw rod 4 installed on the rotating bracket 31 can be driven in the vertical state under the driving of the pitching mechanism 3. Convert in the horizontal state; the rotary drive device 2 is installed on the rotary support 31, and the rotary drive device 2 includes a first drive motor 21, a first gear 22 connected with the output shaft of the first drive...

Embodiment 2

[0072] The difference between this embodiment and the above-mentioned embodiment is that, as shown in the figure, the transmission structure includes a first gear 22 connected to the output shaft of the first drive motor 21, meshed with the first gear 22 and connected with The second gear 26 that is coaxially fixedly connected to the screw 4 connecting piece is connected by several deep groove ball bearings 27 between the screw 4 connecting piece and the rotating bracket 31, and the middle section of the screw 4 connecting piece has an extension The second gear 26 is bolted to the extension. When the screw rod 4 rotating device is working, the first drive motor 21 works to drive the first gear 22 to rotate, the second gear 26 meshes with the first gear 22 to rotate, and the screw rod 4 connecting piece rotates together with the second gear 26 so that it is installed on the The screw 4 in the screw 4 connection rotates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com