Clamping device for sensor production

A clamping device and sensor technology, used in workpiece clamping devices, manufacturing tools, etc., can solve the problems of uncontrollable force, economic damage to sensors, low work efficiency, etc., to avoid economic losses, good device stability, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

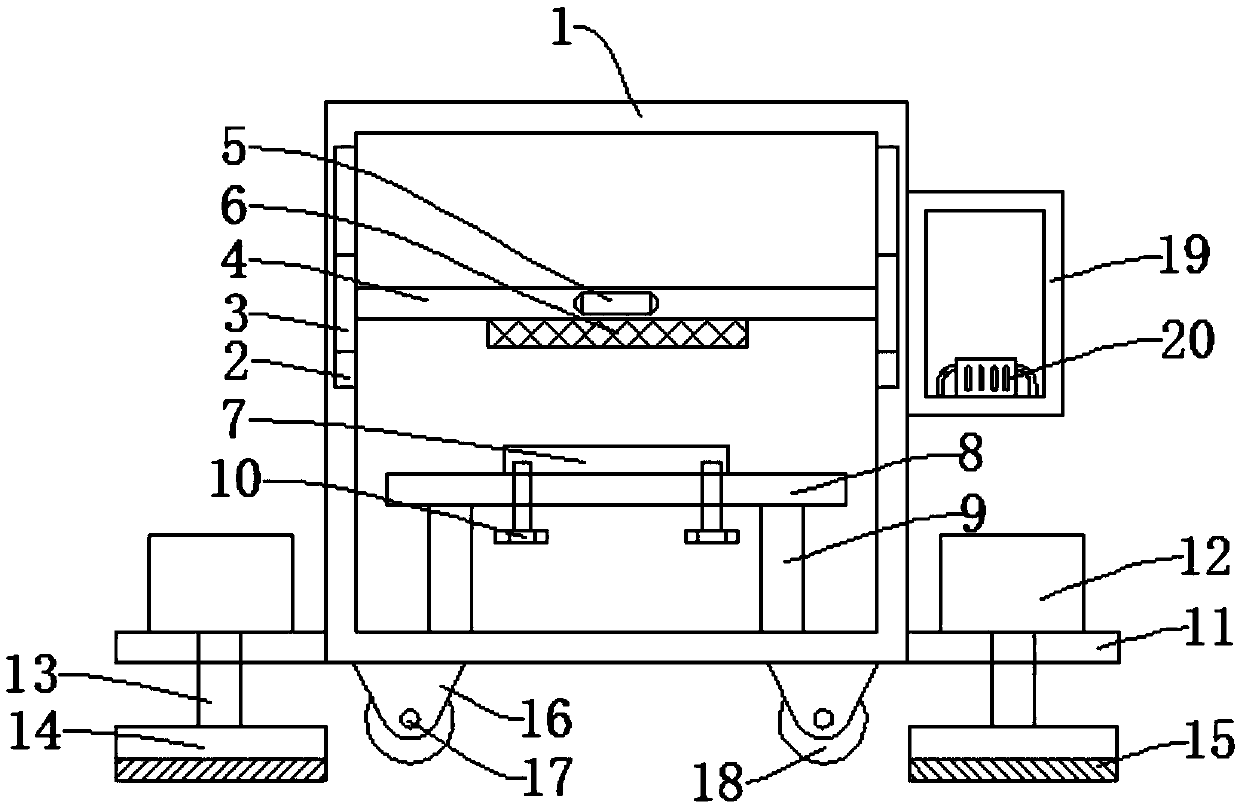

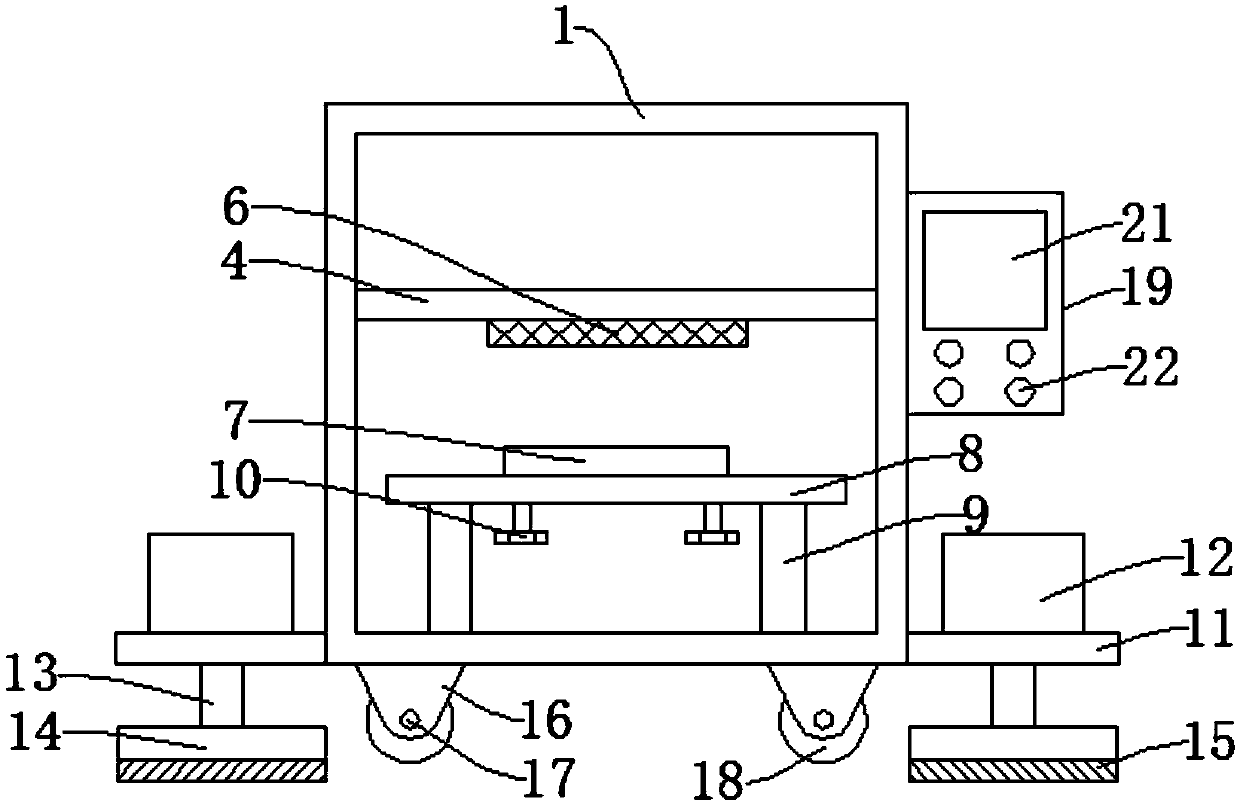

[0021] The present invention will be further described below in conjunction with accompanying drawing:

[0022] like Figure 1-Figure 4 As shown, a clamping device for sensor production includes a box body 1, a chute 2, an electric slider 3, and a moving plate 4. The box body 1 is provided with a chute 2, and the chute 2 is used for the electric slider 3 Moving, there is an electric slider 3 inside the chute 2, the electric slider 3 is used to drive the moving plate 4 up and down, a moving plate 4 is arranged between the electric sliders 3, and the moving plate 4 is used to squeeze the sensor A pressure sensor 5 is provided, and the model of the pressure sensor 5 is PT124G-113, which is used to detect the pressure. A protection pad 6 is provided under the moving plate 4, and the protection pad 6 is used to protect the sensor. For clamping the sensor, a workbench 8 is arranged under the fixture 7, and the workbench 8 is used to place the fixture 7. A fixing screw 10 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com