Segmenting device for rice cake production

A technology for cutting into sections and rice cakes, applied in metal processing, food science, etc., can solve the problems of single function, poor practicability, low work efficiency, etc., and achieve the effect of high degree of automation, favorable for popularization and use, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

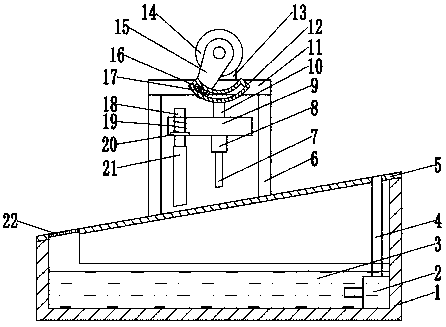

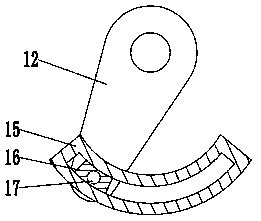

[0023] see Figure 1-3 , a cutting device for rice cake production, comprising a processing table 1, a slant plate 5 is arranged on the top of the processing table 1, and the surface of the sloping plate 5 is made of mirror stainless steel material, and the rear side of the processing table 1 is fixedly connected to a support frame 6, and the support frame 6 The top is fixedly connected to the fixed plate 11, the top of the fixed plate 11 is fixedly connected to the motor base 13, the top of the motor base 13 is fixedly connected to the motor 14, the output shaft of the motor 14 is fixedly connected to the rotating arm 15, and the front side of the other end of the rotating arm 15 is fixedly connected to the short rod 17. The outer side of the bar 17 is rotated to connect the slider 16, the outer side of the slider 16 is slidably connected to the arc frame 12, the bottom of the arc frame 12 is fixedly connected to the connecting rod 10, and the bottom of the connecting rod 10 i...

Embodiment 2

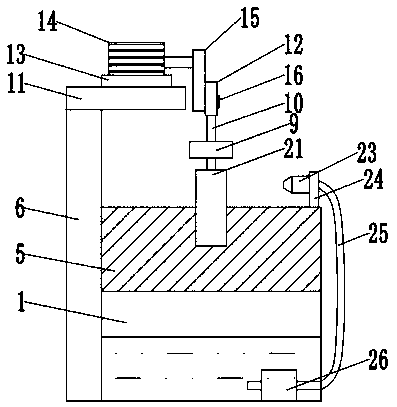

[0026] see image 3 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that a second water pump 26 is arranged in the water tank 2, the output end of the second water pump 26 is fixedly connected to the connecting pipe 25, and the surface of the swash plate 5 is fixedly connected to Mounting seat 24, a water spray device 23 is installed in the mounting seat 24, the right side of the water spray device 23 is fixedly connected to the connecting pipe 25, and in the process of the blade 7 cutting the rice cake, the second water pump 26 passes the water in the water tank 2 through the connecting pipe 25 , pumped into the water spray device 23, the water spray device 23 continues to spray water against the blade 7 to prevent the rice cake from adhering to the blade 7 during cutting.

[0027] In the implementation process of the present invention, the first water pump 2 is turned on, and the water in the water tank 2 is sprayed on the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com