Bamboo tube preparation device

A technology for preparing a device and a bamboo tube, which is applied in the directions of manufacturing tools, mechanical equipment, metal processing equipment, etc., can solve the problems of difficulty in centralized treatment of bamboo partitions, incomplete opening of bamboo partitions, structural damage of bamboo tubes, etc., and achieves a high degree of automation. The effect of small damage to bamboo tube structure and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

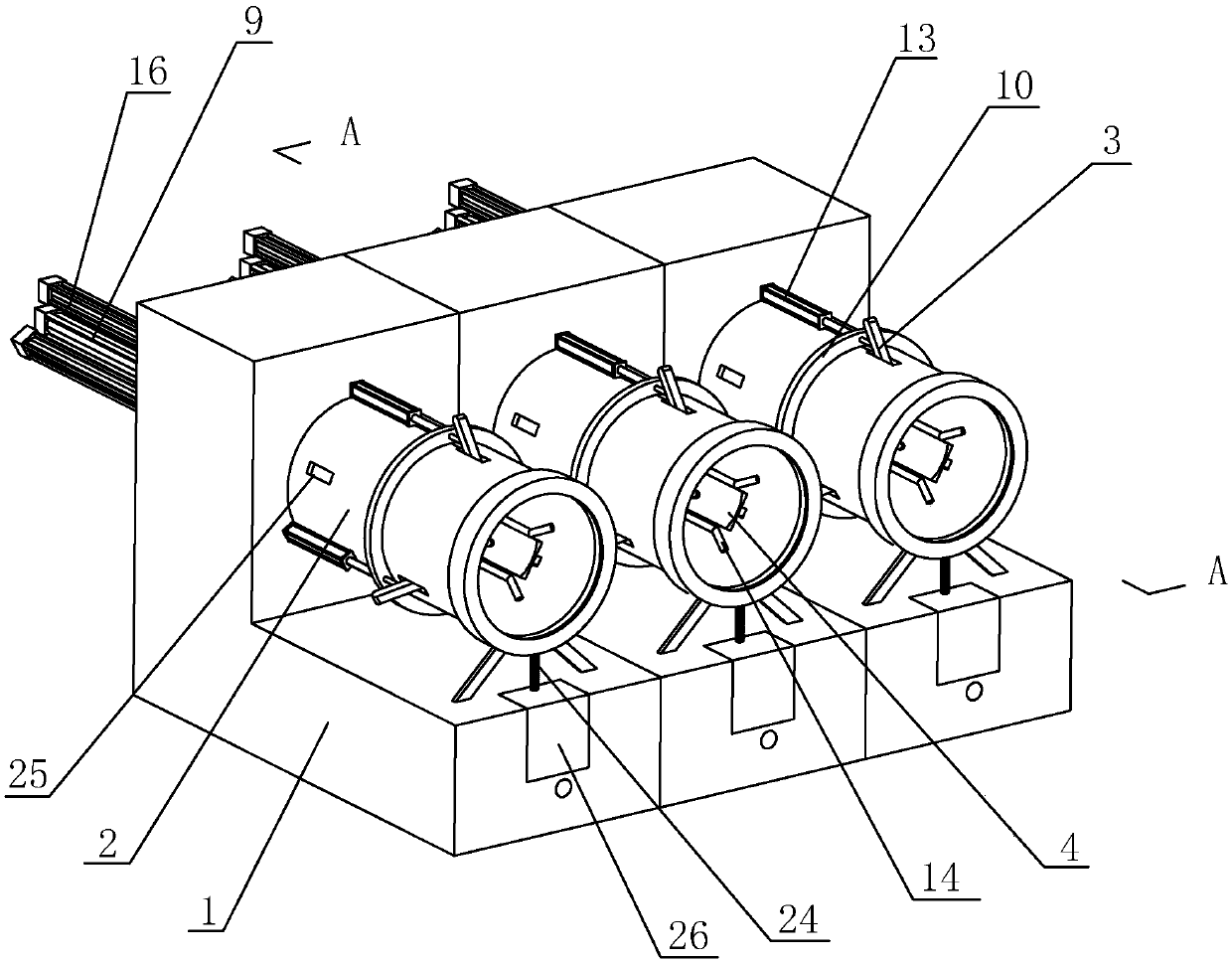

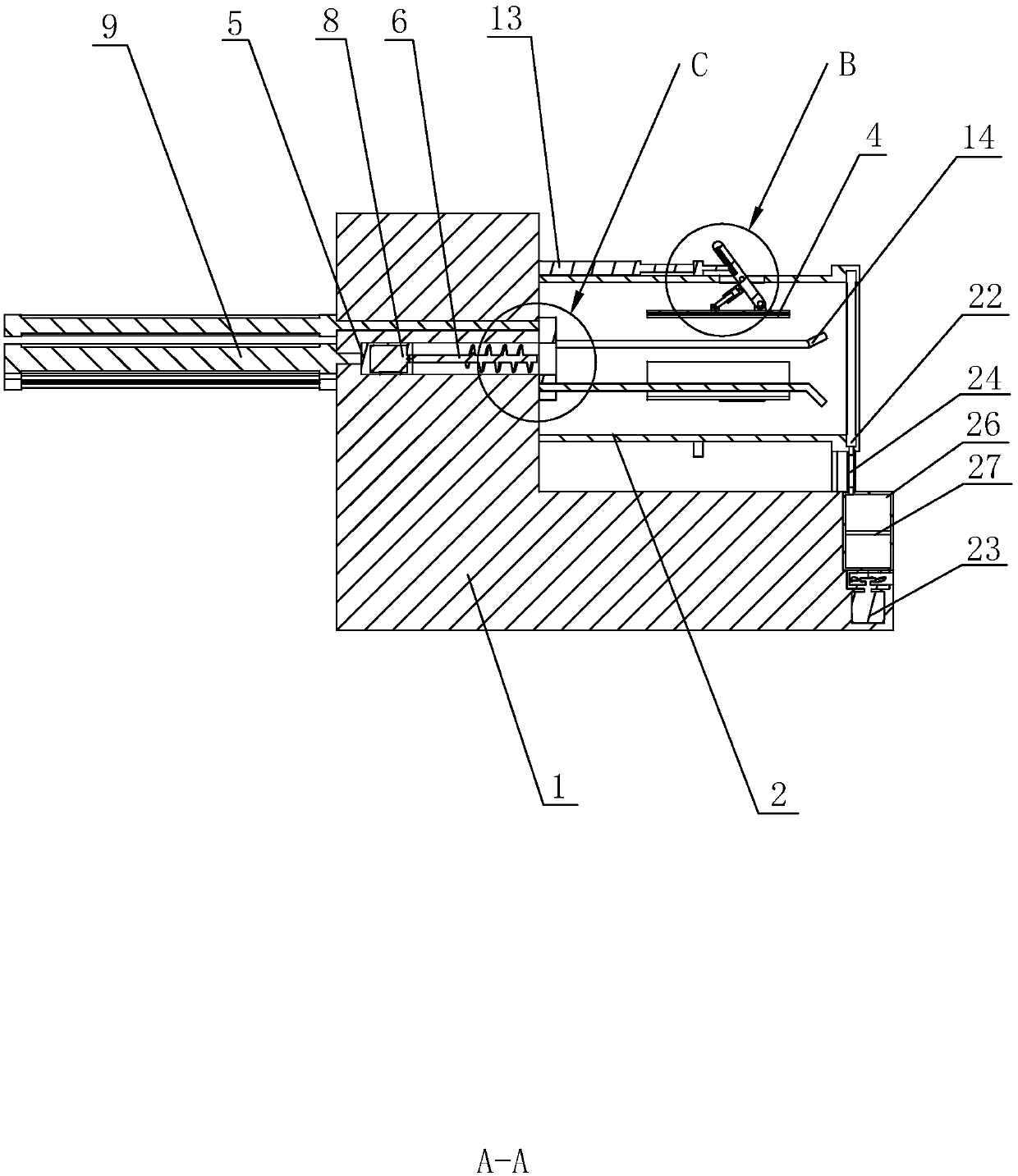

[0036] refer to figure 1 , is a kind of bamboo tube preparation device disclosed in the present invention, comprises machine platform 1, and machine platform 1 is provided with multiple sets of clamping devices, bamboo passing devices and unloading devices. The clamping devices are arranged side by side on the upper end of the machine 1 and are used to fix the position of the bamboo tube. The bamboo opening device is set corresponding to the clamping device and can open up bamboo tubes of different diameters. After the processing of the bamboo tubes is completed, the unloading device sends the bamboo tubes out of the machine 1 .

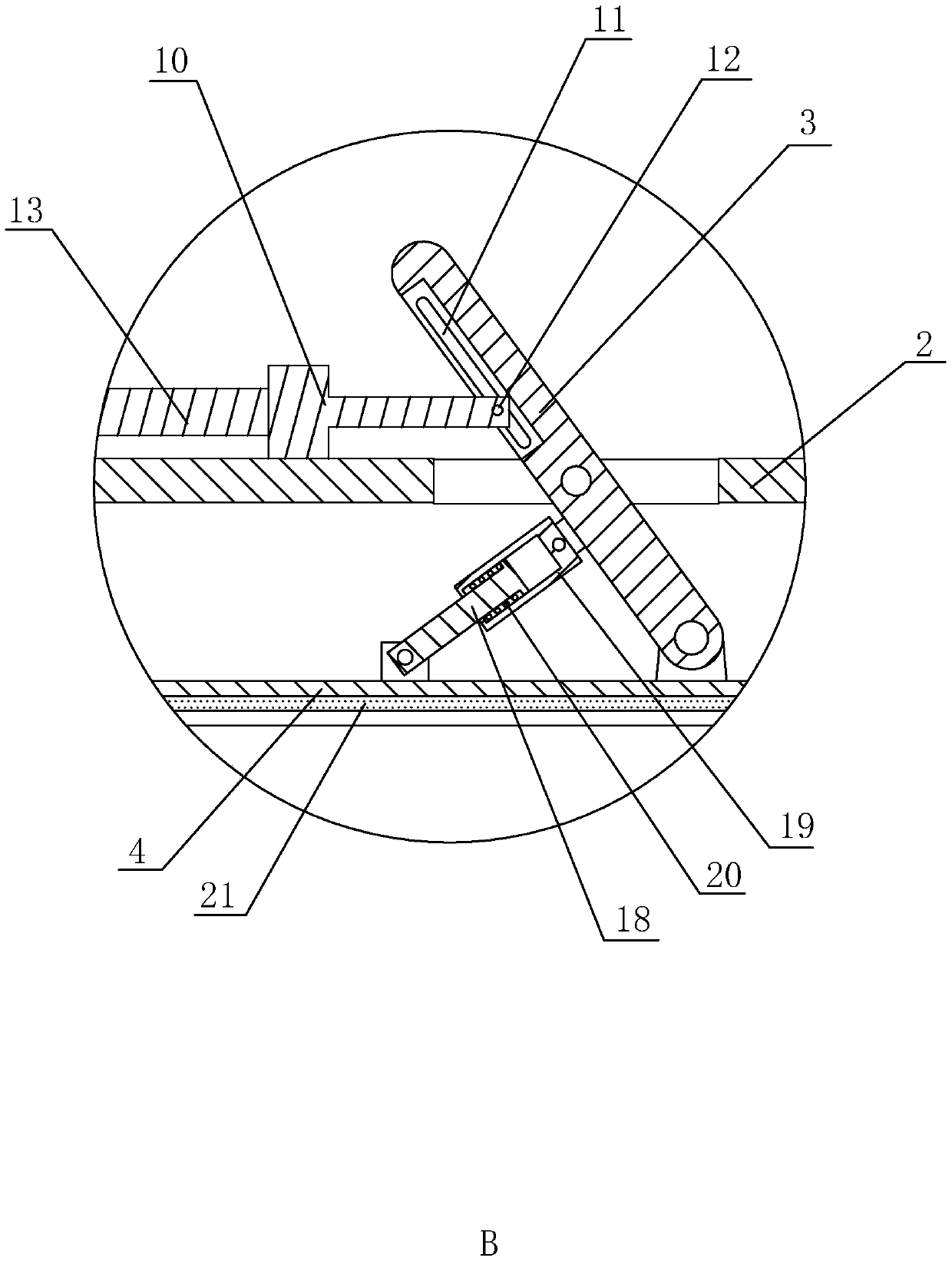

[0037] refer to figure 1 with figure 2 The clamping device includes a positioning cylinder 2 fixed on the top of the machine table 1. The positioning cylinder 2 is horizontally arranged and its inner wall is hingedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com