A processing method for anisotropy of round bamboo modified by laser

A processing method and technology of round bamboo, which are applied in wood processing utensils, manufacturing tools, reed/straw treatment, etc., can solve the problems of reduced anisotropy, easy cracking of round bamboo, reduction of internal stress of round bamboo shape, etc., to reduce energy Loss, efficient utilization, the effect of improving anti-splitting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

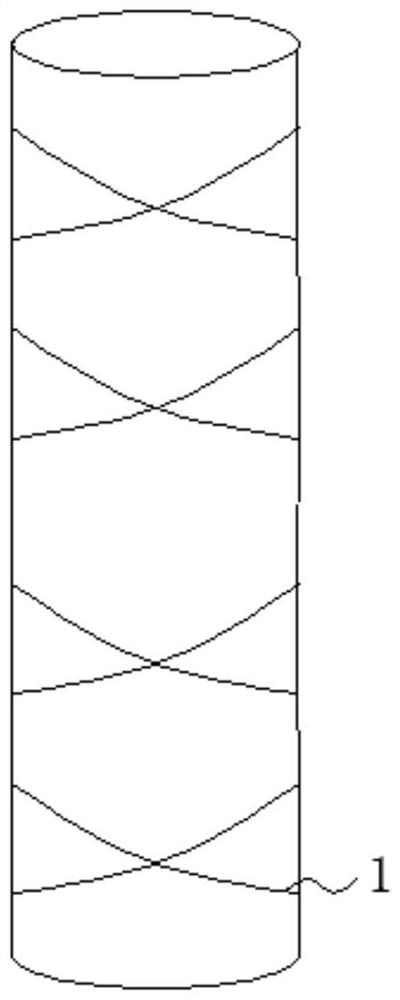

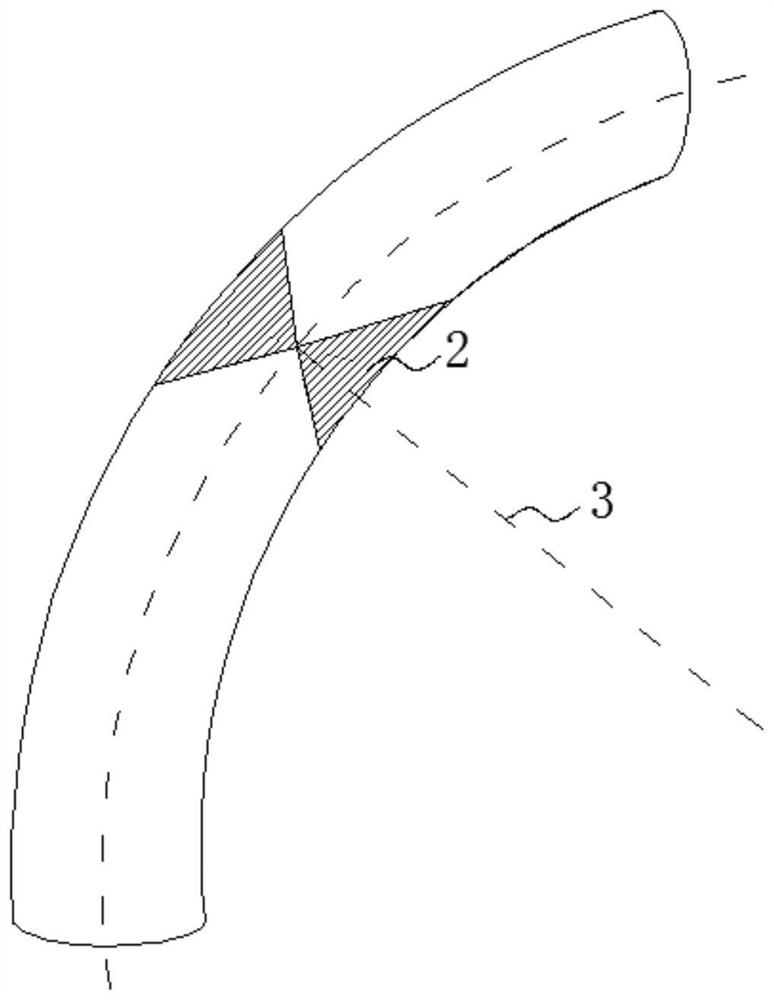

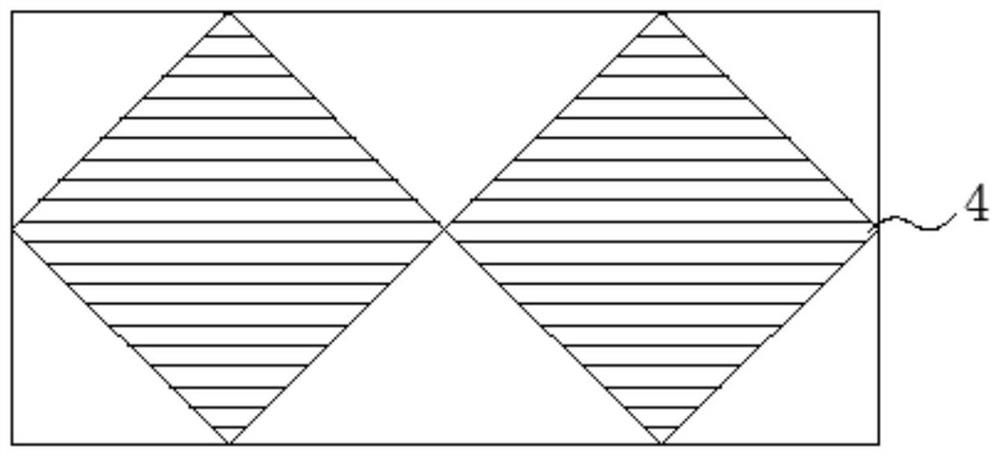

[0044] A processing method for modifying the anisotropy of round bamboo by laser, the round bamboo is irradiated by laser, which specifically includes the following steps:

[0045] Step 1: Determine the density and age of the round bamboo;

[0046] Step 2: According to the use status of the round bamboo, gradually determine the processing position and range of the laser device, and the expected processing thickness. In order to ensure the modification effect of laser irradiation and the stability of the performance of the round bamboo, the processing range of the laser device is not less than the total surface area of the round bamboo. The pre-processing thickness of the laser device is 3% to 40% of the thickness of the round bamboo wall. On the one hand, it ensures that the round bamboo at the part to be treated can absorb enough energy to realize the internal lignin and cellulose, hemicellulose The three-dimensional space cross-linking effect, on the other hand, also ensur...

Embodiment 2

[0066] A processing method for modifying the anisotropy of round bamboo by laser, the round bamboo is irradiated by laser, which specifically includes the following steps:

[0067] Step 1: Determine the density and age of the round bamboo;

[0068] Step 2: According to the use status of the round bamboo, gradually determine the processing position and range of the laser device, and the expected processing thickness. In order to ensure the modification effect of laser irradiation and the stability of the performance of the round bamboo, the processing range of the laser device is not less than the total surface area of the round bamboo. The pre-processing thickness of the laser device is 3% to 40% of the thickness of the round bamboo wall. On the one hand, it ensures that the round bamboo at the part to be treated can absorb enough energy to realize the internal lignin and cellulose, hemicellulose The three-dimensional space cross-linking effect, on the other hand, also ensur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com