Aroma-increasing canned rice device and canning method

A technology of canning rice and canning, which is applied in the direction of jars, packaging, transportation and packaging, etc., can solve the problems of rice movement state, little research on collision and damage degree, broken and damaged rice grains, low water content, etc., and achieve airtightness Good, reduces water absorption, prevents fat oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

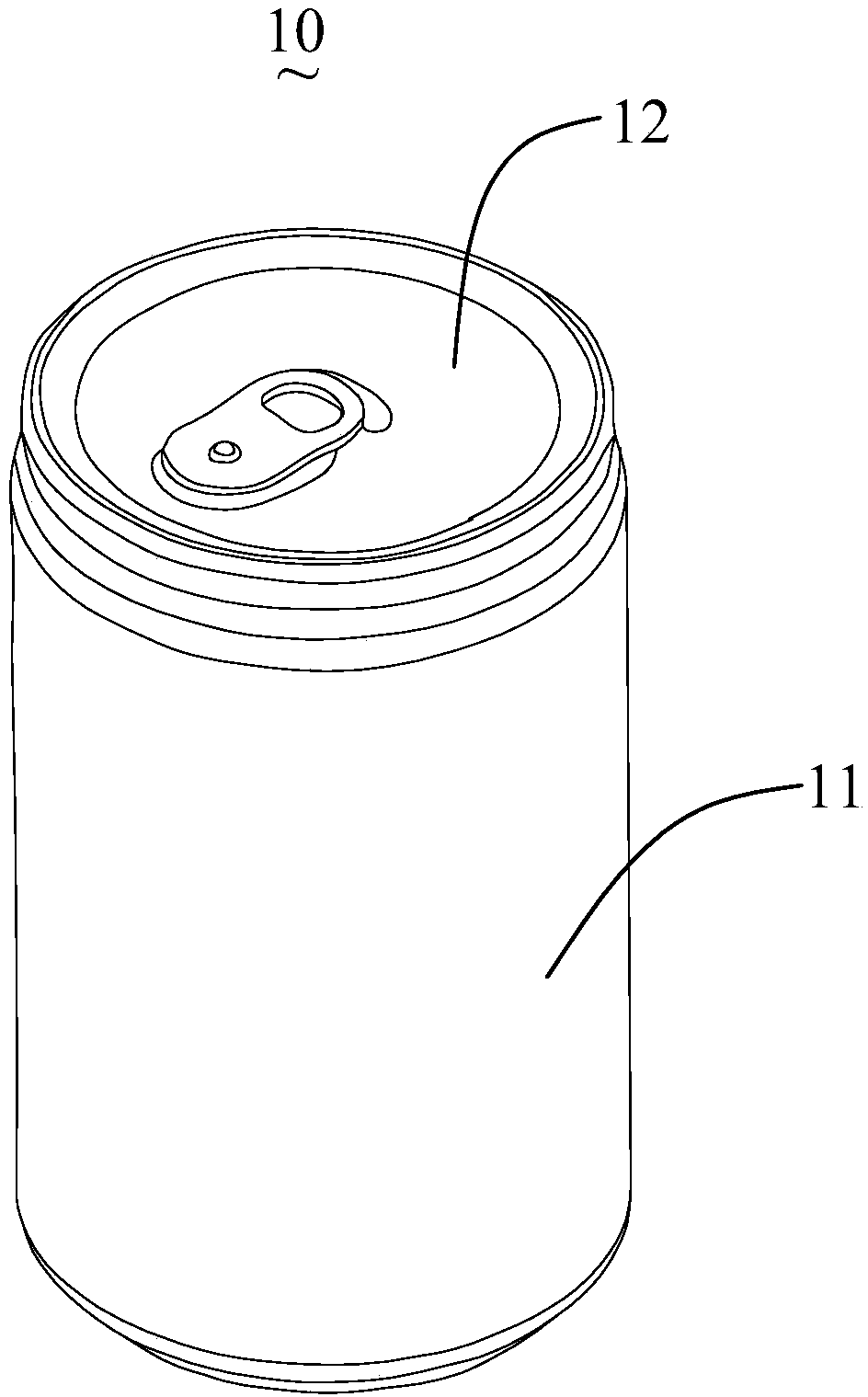

[0030] see figure 1 The aromatized tin can rice described in the first preferred embodiment, the aromatized canned rice 10 includes: an iron can 11, and rice contained in the iron can. In this embodiment, the iron can The tank 11 is tinplate; certainly the iron tank can also be replaced by an aluminum tank. Compared with plastic packaging or kraft paper packaging on the market, the iron can 11 has good airtightness and can block light, can better isolate oxygen and water in the air, and retain the aroma and nutrition in the rice. The aroma component 2-acetyl-1-pyrroline in rice is concentrated on the surface of the rice and is more susceptible to damage by light, oxygen and air. The sealing and shading of the iron can 11 can well prevent the loss of aroma components on the surface of the rice. Keep the rice in a dormant state and prevent fat oxidation; in addition, the iron can 11 has high strength and is not easy to be damaged during storage and transportation.

[0031] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com