Active substrate and preparation method thereof

A technology of substrate and cover plate, applied in the field of active substrate and its preparation, can solve the problems of poor flatness of rewiring layer and inability to meet the requirements of sealed space, and achieve the effect of improving flatness, avoiding influence and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

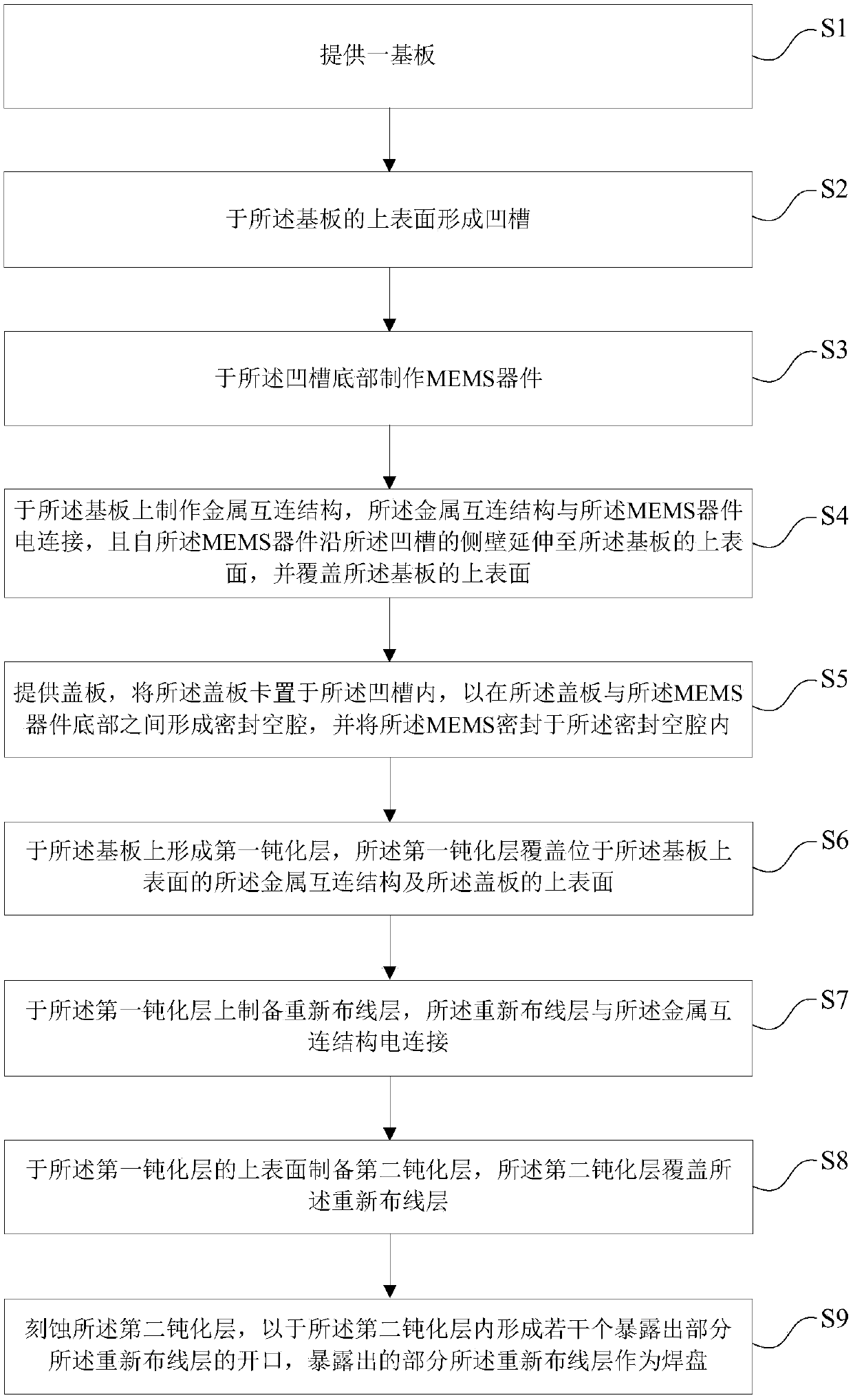

[0054] see figure 1 , the present embodiment provides a kind of preparation method of active substrate, and the preparation method of described active substrate comprises the following steps:

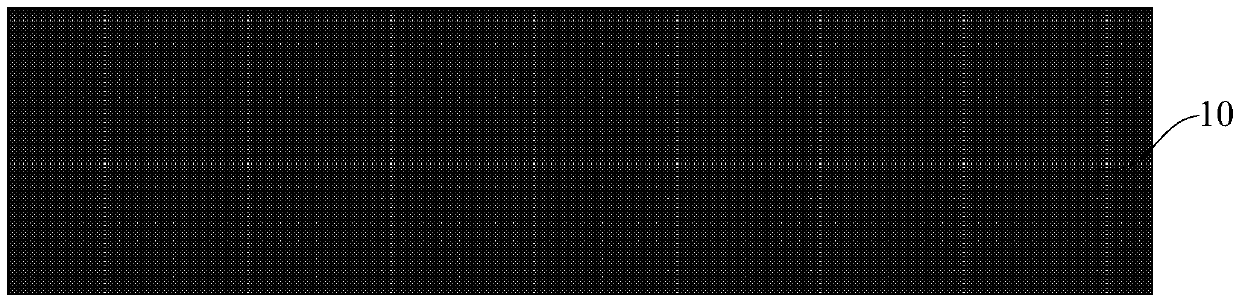

[0055] 1) providing a substrate;

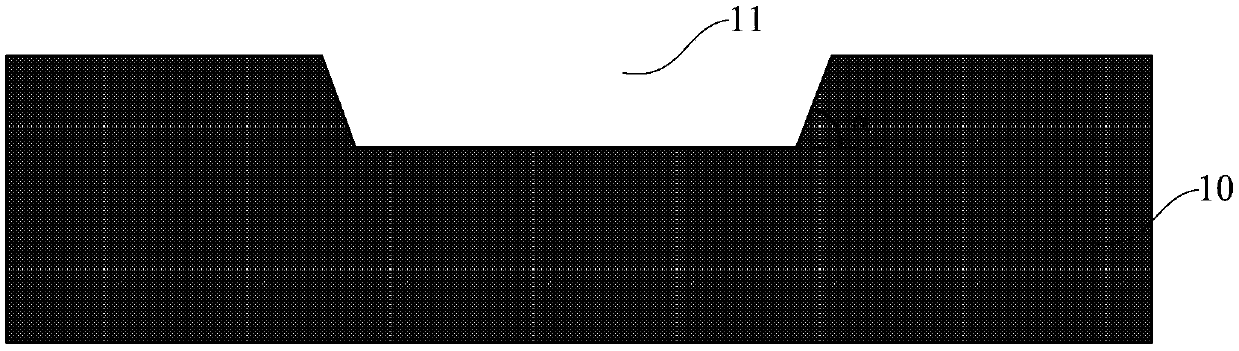

[0056] 2) forming grooves on the upper surface of the substrate;

[0057] 3) making a MEMS device at the bottom of the groove;

[0058] 4) making a metal interconnection structure on the substrate, the metal interconnection structure is electrically connected to the MEMS device, and extends from the MEMS device along the sidewall of the groove to the upper surface of the substrate, and cover the upper surface of the substrate;

[0059]5) Provide a cover plate, place the cover plate in the groove to form a sealed cavity between the cover plate and the bottom of the MEMS device, and seal the MEMS in the sealed cavity cavity;

[0060] 6) forming a first passivation layer on the substrate, the first passivation layer covering the metal interconnect st...

Embodiment 2

[0106] read on Figure 10 , the present invention also provides an active substrate, which includes: a substrate 10, a groove 11 is formed on the upper surface of the substrate 10; a MEMS device 12, the MEMS device 12 is located in the groove 11 Bottom; metal interconnection structure 13, described metal interconnection structure 13 is electrically connected with described MEMS device 12, and described metal interconnection structure 13 extends from described MEMS device 12 along the sidewall of described groove 11 to the described The upper surface of the substrate 10; the cover plate 14, the cover plate 14 is clamped inside the groove 11 to form a sealed cavity 111 between the cover plate 11 and the bottom of the MEMS device 12; The MEMS device 12 is sealed in the sealed cavity 111; a first passivation layer 15, the first passivation layer 15 is located on the upper surface of the substrate 10, and the first passivation layer 15 covers the The upper surface of the metal int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com