A packaging structure of an image sensor and its packaging process

An image sensor and packaging structure technology, which is applied to electric solid-state devices, semiconductor devices, radiation control devices, etc., can solve the problems of inability to meet the packaging requirements of image sensors, high packaging cost, and high height, so as to save the wire bonding process. , The effect of reducing packaging costs and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

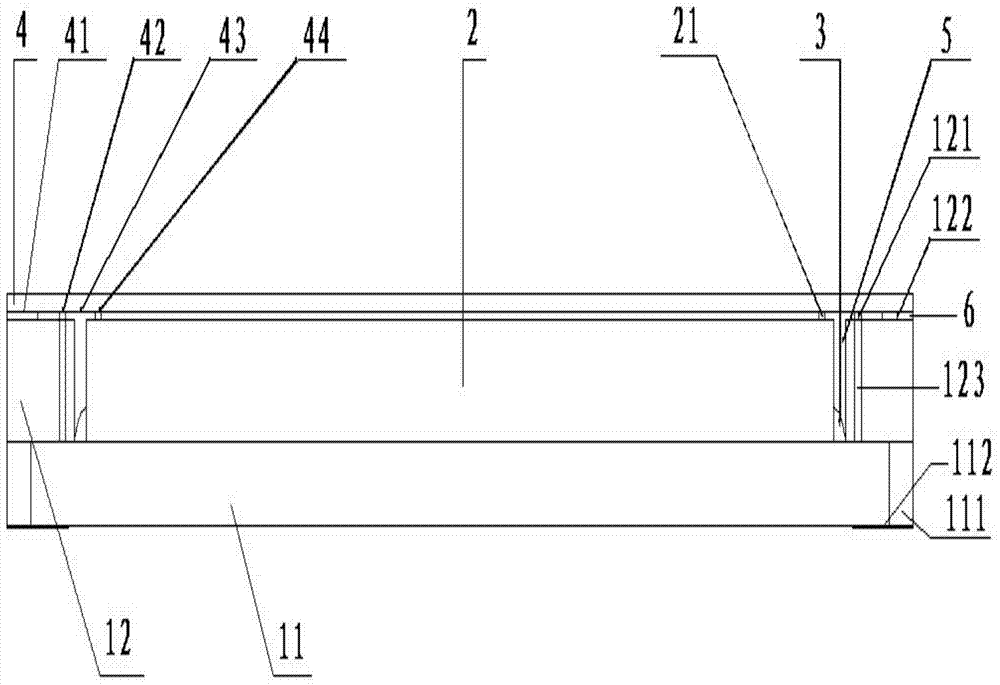

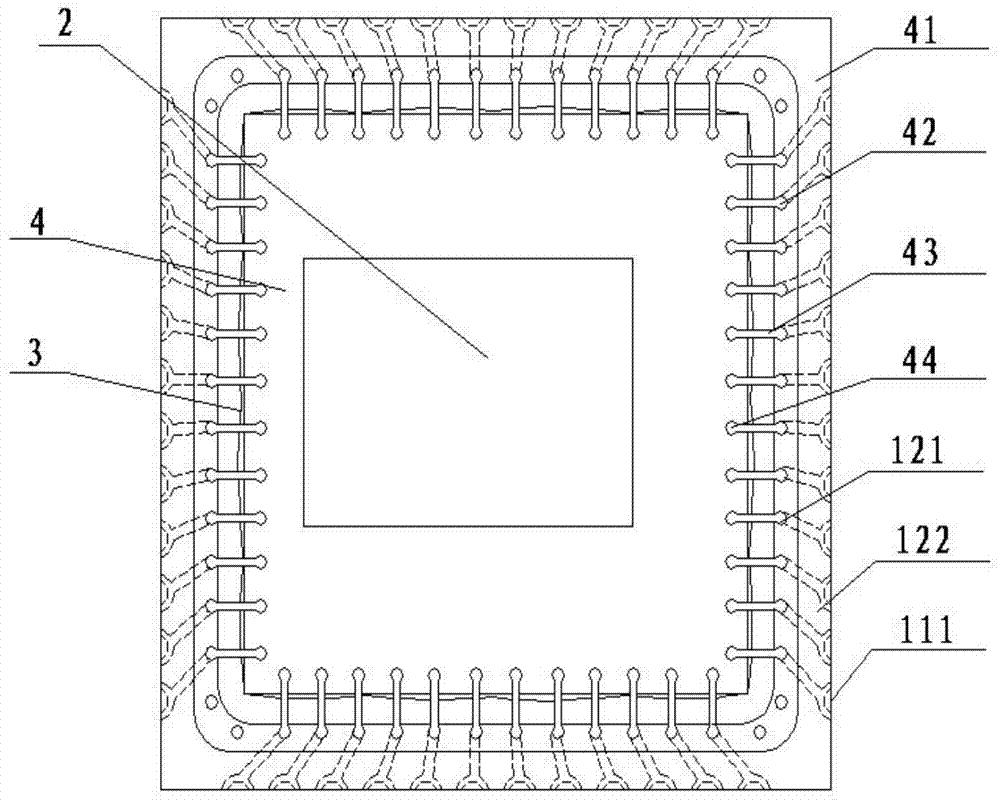

[0052] Embodiment: A 0.70mm pitch PLCC48 packaging structure and packaging process for an ultra-thin image sensor with a size of 10mm×10mm×0.85mm, including the following steps:

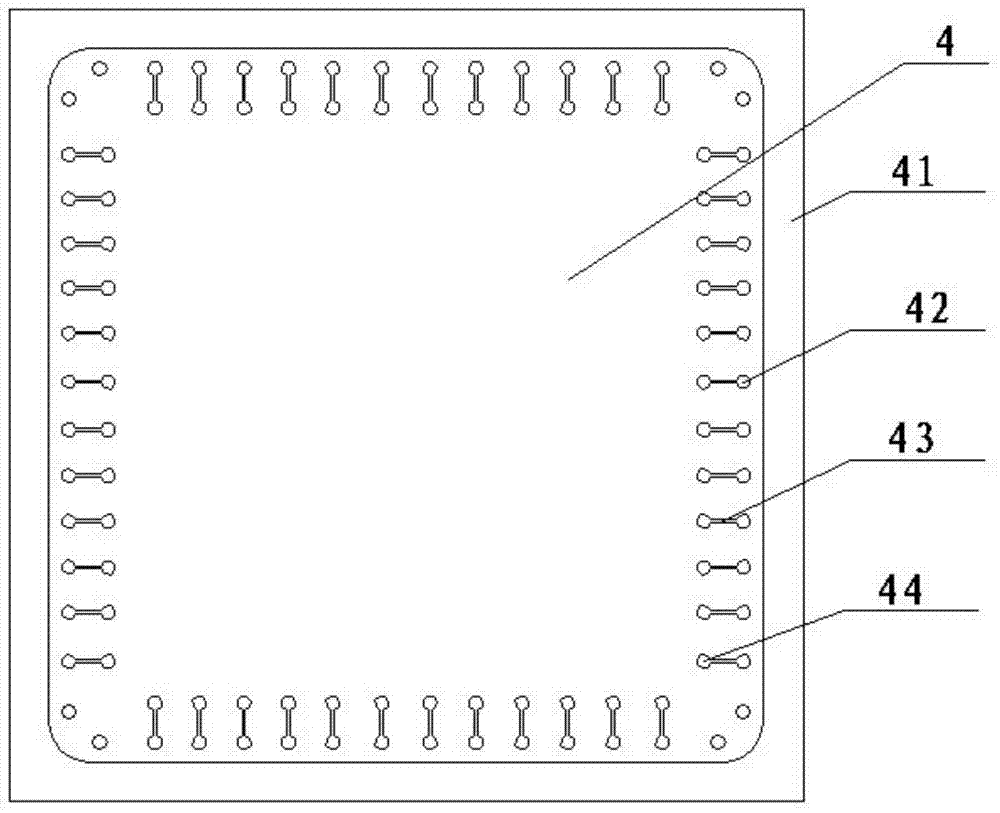

[0053] Firstly, the SCHOTT AF32 series eco aluminoborosilicate glass with a thickness of 0.10mm is photolithographically etched and evaporated on one side of the film glass through a mask to prepare a sealing ring 41, an outer pad 42, an interconnection line 43, and an inner pad 44 , the metal layer is a Cr-Ni-Ag layer with a thickness of 600 angstroms to 2000 angstroms, 2000 angstroms to 7000 angstroms, and 500 angstroms to 1000 angstroms; finally, it is cut into a thin film glass window 4 of 9.8mm×9.8mm×0.05mm, such as figure 1 ;

[0054] Secondly, use FR4 material and copper foil to make pad 121 with support part, support part sealing ring 122, PLCC48 substrate 1 of 10mm×10mm×0.70mm with buried hole 123, base outer pad 112, semicircular through hole 111, thermally spray SnAg0.3Cu0. 7 Solder laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com