A double-cell continuous fermentation method with high ethanol production

A fermentation method and ethanol technology, which is applied in the field of double-cell continuous fermentation of high-yield ethanol, can solve the problems that the ethanol fermentation level cannot meet the needs of industrialization, the tolerance of high-concentration ethanol inhibitors is poor, and the efficiency of cellulose enzymatic hydrolysis is low. Improve ethanol production and biomass utilization, promote the growth of chlorella, and improve the effect of fermentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

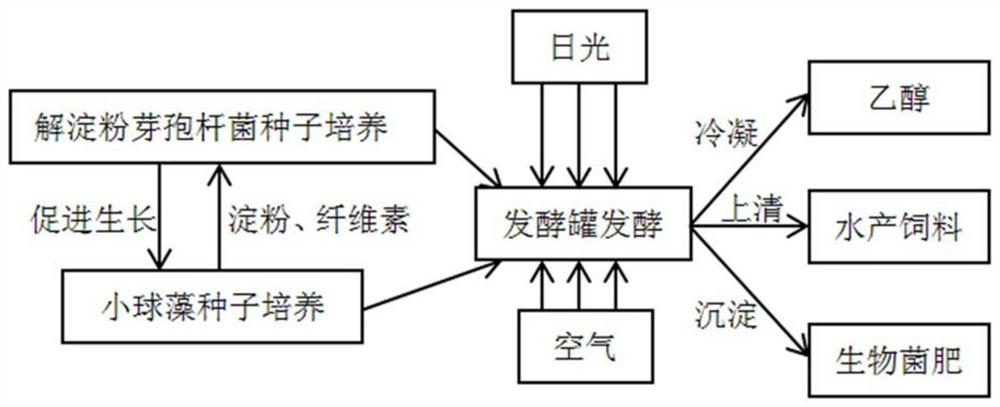

[0021] A two-cell continuous fermentation method for high ethanol production, such as figure 1 shown, including the following steps:

[0022] 1. The composition of Bacillus amyloliquefaciens seed medium is: tryptone 10g / L, yeast extract 5g / L, sodium chloride 10g / L. The seed cultivation process of Bacillus amyloliquefaciens was carried out in a triangular flask, the cultivation temperature was 28°C, the rotation speed of the shaker was 160r / min, and the cultivation time was 24h.

[0023] 2. The composition of the chlorella seed medium is: glucose 10g / L, potassium nitrate 1.011g / L, sodium dihydrogen phosphate 0.907g / L, disodium hydrogen phosphate 0.946g / L, magnesium sulfate 0.246g / L, chloride Calcium 0.015g / L, ferrous sulfate 0.007g / L, zinc sulfate 0.0003g / L, manganese sulfate 0.0002g / L, ammonium chloride 0.5g / L. The cultivation temperature of the chlorella seeds is 25° C., and the cultivation time is 5 to 7 days under light.

[0024] 3. Mix the Bacillus amyloliquefaciens and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com