Vortex hedging-based reciprocating disturbing and shearing pulping equipment

A vortex and pulping technology, applied in the field of pulping equipment based on vortex hedging and reciprocating shear pulping, can solve the problems of low pulping efficiency and low pulp quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

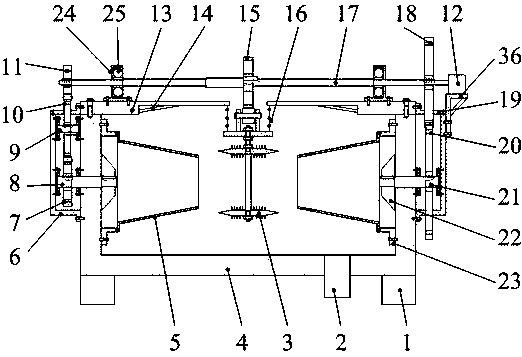

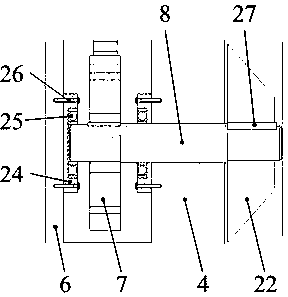

[0047] Such as figure 1 and figure 2 As shown, a pulping equipment based on vortex hedging and reciprocating shearing type pulping mainly includes a slurry generation device, a power drive device, a vortex hedging device and a reciprocating shearing device, and the power drive device is installed on the pulp generating device Above the device, the vortex hedging device is installed on both sides inside the slurry generating device, and the reciprocating shearing device is installed at the center of the slurry generating device.

[0048] The present invention realizes the generation and output of slurry through the slurry generating device, that is, the crushed material is broken and decomposed in the barrel 4 of the slurry generating device to generate slurry, and the slurry is output through the slurry outlet 2; the power drive device is The vortex counter device and the reciprocating scrambling device provide power drive, that is, the impeller rotor 22 in the vortex counte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com