Assembly type reinforced concrete column construction process based on prefabricated standard assembling pieces

A reinforced concrete column and prefabricated concrete technology, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of large weight and volume of a single prefabricated column, cumbersome transportation and installation work, and consume large formwork materials, so as to simplify construction process, shorten the construction period, and reduce the effect of project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

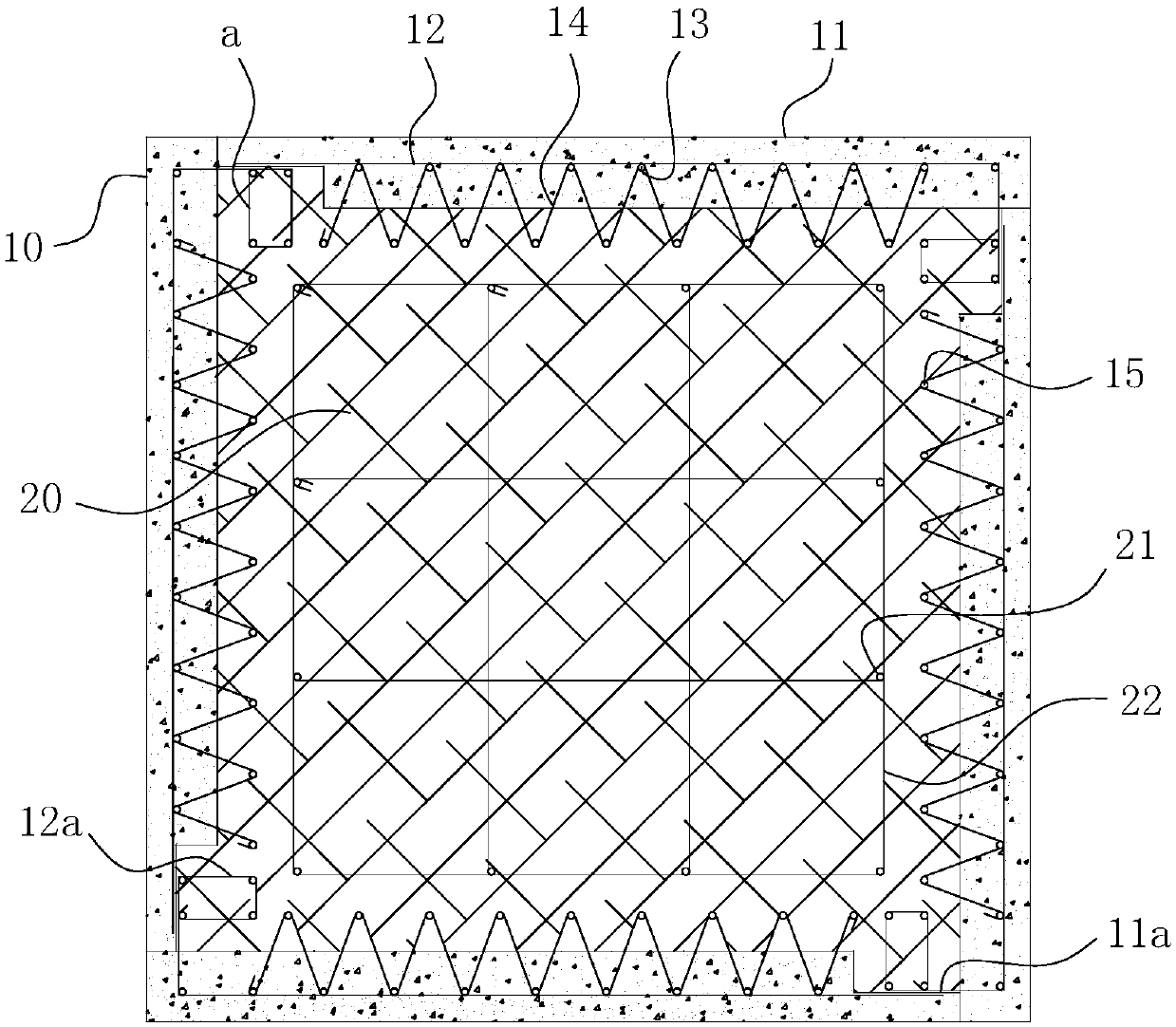

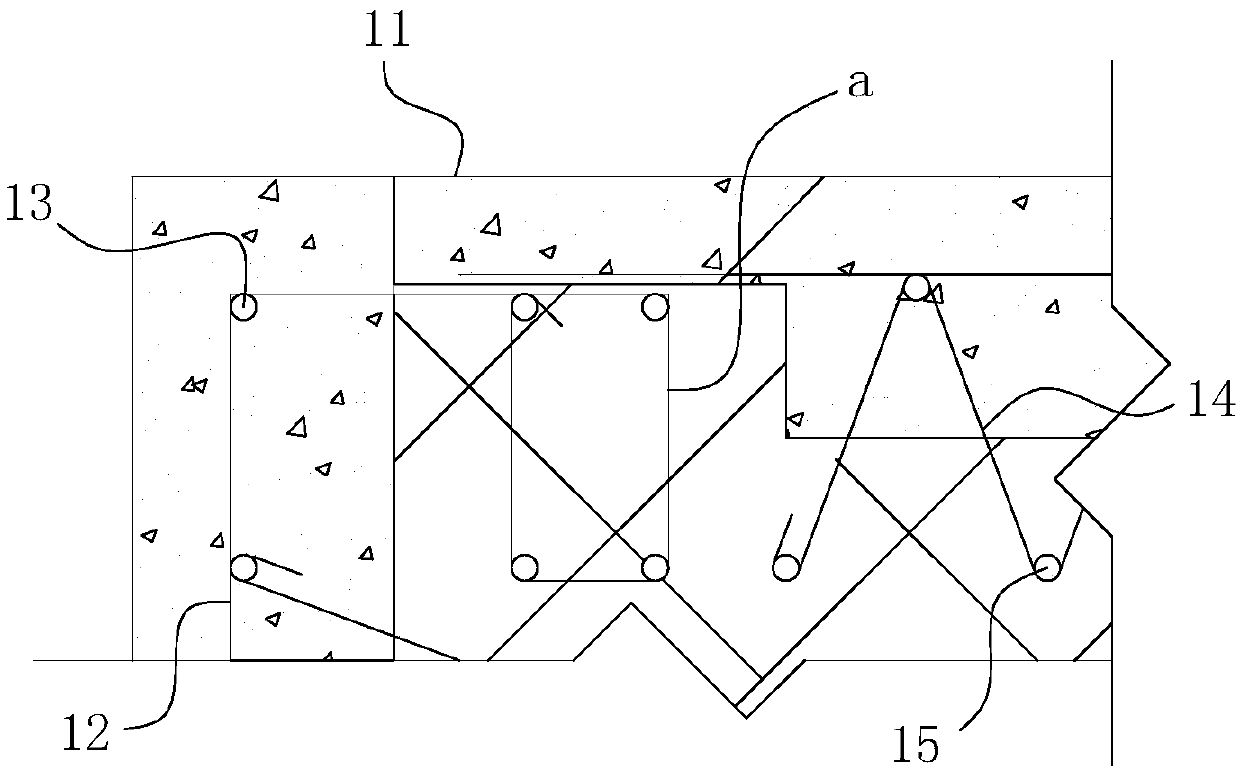

[0048] In the first embodiment, the prefabricated reinforced concrete column is a solid rectangular prefabricated reinforced concrete column.

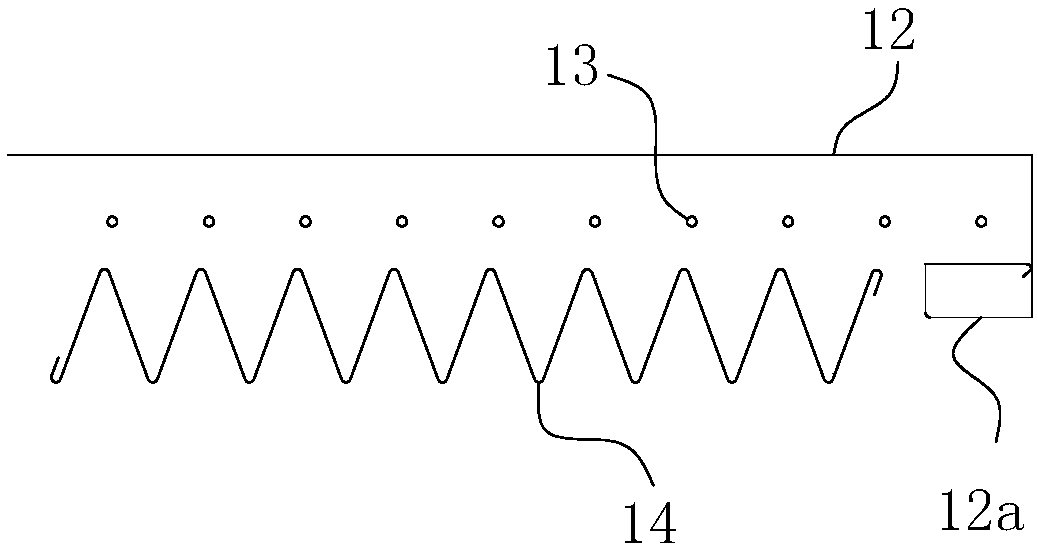

[0049] Such as Figure 1-2 As shown, a prefabricated reinforced concrete column is composed of a prefabricated concrete outer layer 10 and an in-situ concrete inner layer 20 enclosed by prefabricated standard assembled pieces, wherein the outer layer prefabricated standard assembled pieces contain steel bar trusses, and Such as Figure 2-3 Shown, steel bar truss is made up of horizontal steel bar 12, longitudinal steel bar 13 and web bar steel bar 14. The horizontal steel bar 12 is connected with the longitudinal steel bar 13 by binding, and extends out of one end of the prefabricated standard assembly piece to form a zigzag closed hoop 12a. The shape of the web steel bar 14 is as follows Figure 2-4 The shown wave shape, and the top of the crest and the longitudinal reinforcement 13 are connected by binding or welding, while the to...

Embodiment 2

[0059] In the second embodiment, the prefabricated reinforced concrete column is a hollow or solid rectangular prefabricated reinforced concrete column.

[0060] Such as Figure 5-6 As shown, the prefabricated reinforced concrete column is also composed of a prefabricated concrete outer layer 10 and a cast-in-place concrete inner layer 20 formed by enclosing the end to end of the prefabricated standard assembly pieces. The cast-in-place concrete inner layer 20 is a hollow or solid section, and the inside is equipped with vertical reinforcement 21, stirrup 22, longitudinal connection reinforcement 15, steel pipe 24 or section steel 23. in the vertical direction as Figure 7 As shown, the prefabricated reinforced concrete column is formed by assembling the prefabricated standard assembly pieces in sections and pouring the cast-in-place concrete inner layer 20 in sections. Complete the connection.

[0061] In the specific implementation process, the steel pipe 24 or section st...

Embodiment 3

[0064] In the third embodiment, the prefabricated reinforced concrete column is a circular prefabricated reinforced concrete column.

[0065] Such as Figure 9 As shown, in the horizontal direction, the prefabricated reinforced concrete column is composed of such as Figure 8 The prefabricated concrete outer layer 10 and the cast-in-place concrete inner layer 20 formed by the fan ring-shaped prefabricated standard assembly pieces enclosed end to end are formed. Wherein, the outer prefabricated standard assembly piece contains steel bar trusses, while the cast-in-place concrete inner layer 20 is a solid section, and is provided with a three-dimensional grid skeleton composed of vertical steel bars 21, stirrup bars 22 and longitudinal connecting steel bars 15. In the vertical direction, the prefabricated reinforced concrete column is formed by assembling the prefabricated standard assembly pieces in sections and pouring the cast-in-place concrete inner layer 20 in sections. Gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com