Graphene heating based assembled background wall

A technology of graphene and background wall, applied in the field of background wall, can solve the problems of poor practicability, difficult to replace the background plate, non-removable background plate, etc., and achieve the effect of convenient movement and temperature increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

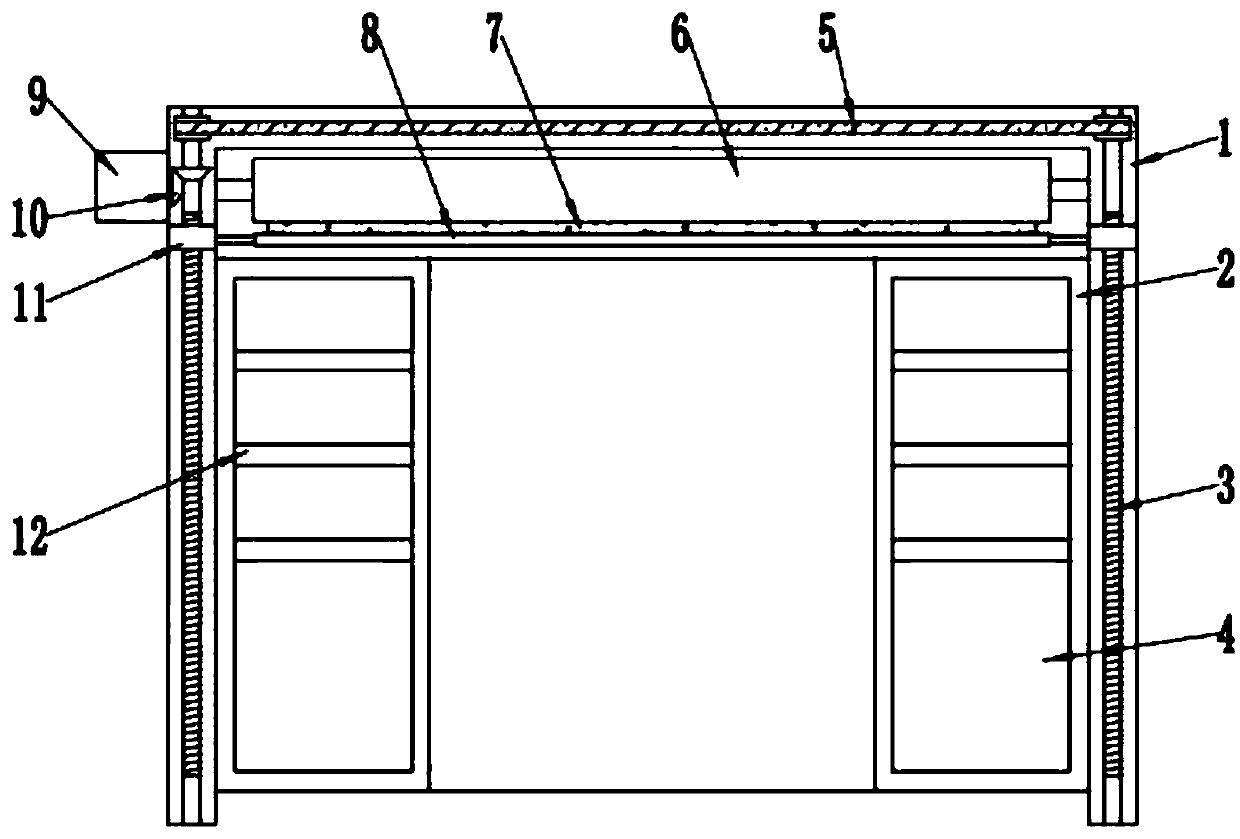

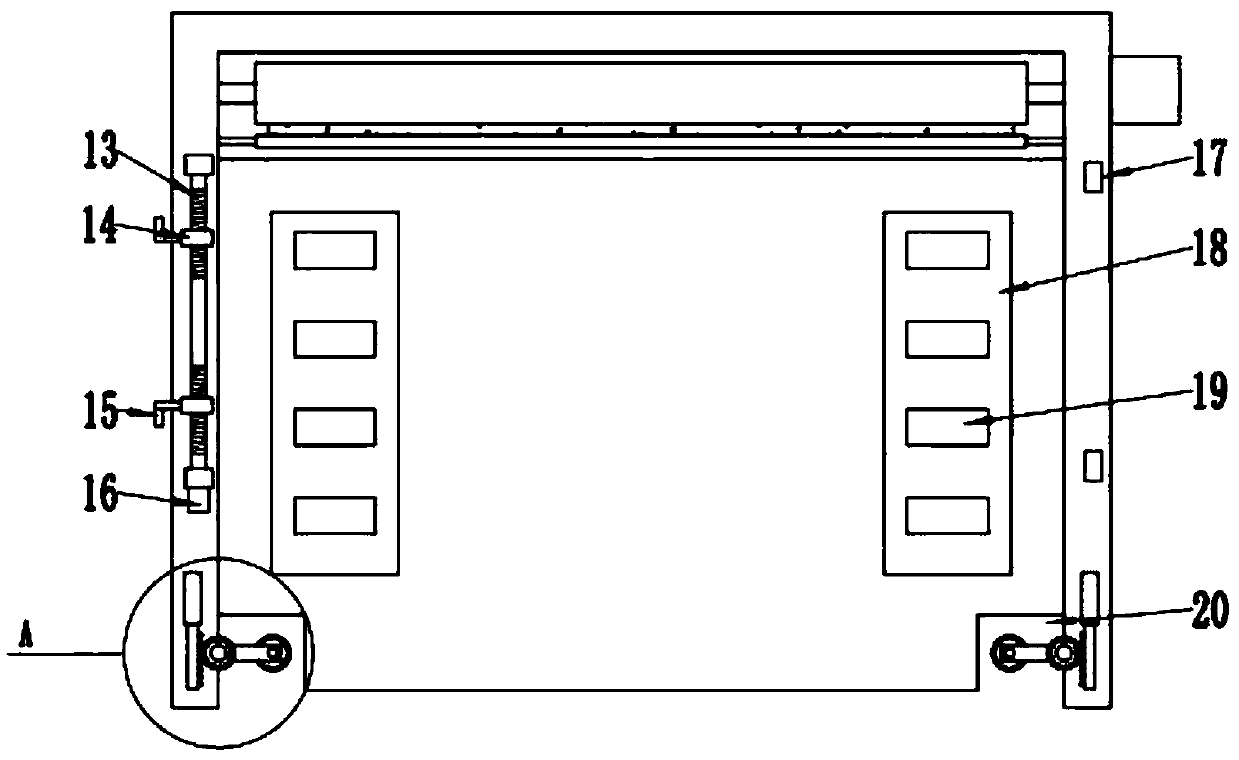

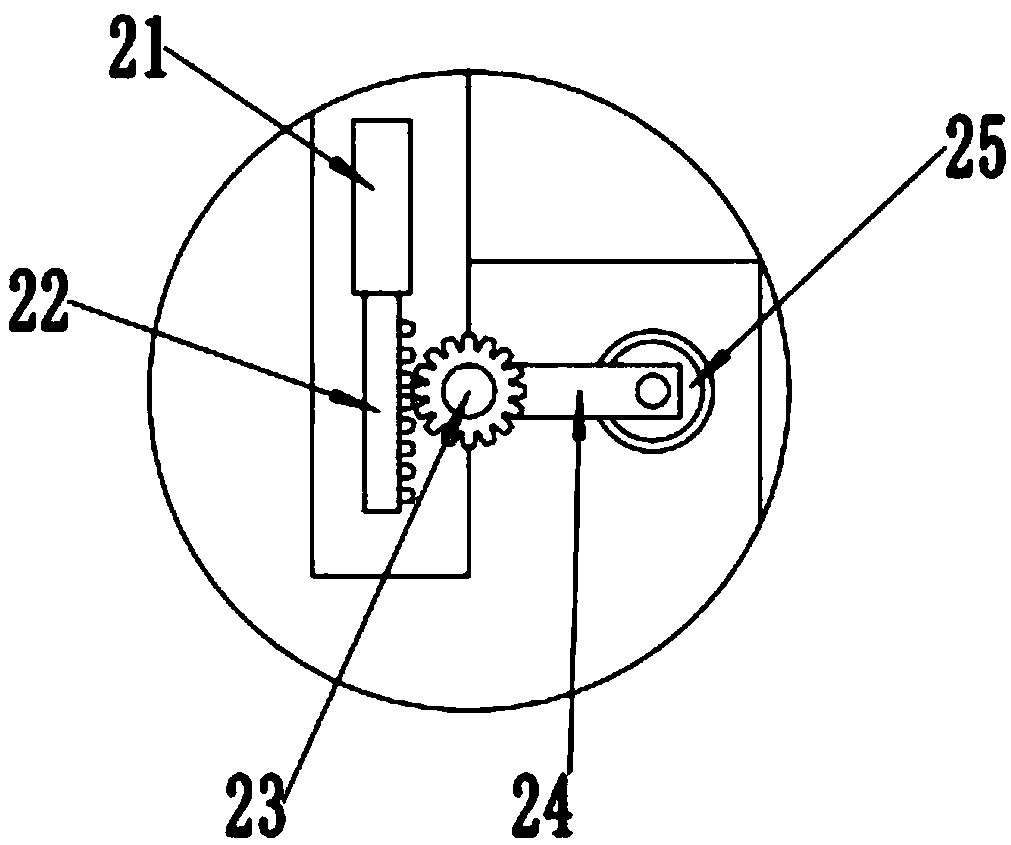

[0027] See Figure 1-4 , A graphene heating assembly background wall, comprising a frame 1 and a background plate 2; the frame 1 is an inverted U-shaped frame structure, and the left and right sides of the background plate 2 are fixedly installed on the inner side of the frame 1, respectively, Two storage cavities 4 are symmetrically provided on the left and right sides of the front part of the background plate 2. A number of partitions 12 are fixedly installed inside the storage chamber 4. The partitions 12 divide the interior of the storage chamber 4 into multiple cavities for placing sundries. The background plate 2 is an integrated structure composed of a front panel and a back panel. The specific material of the front panel is silica gel. A disc-shaped heating plate 26 is fixedly installed inside the front panel. The heating plate 26 generates heat and passes The front panel radiates the interior of the room to increase the internal temperature of the room; the left and ri...

Embodiment 2

[0031] See Figure 1-4 , A graphene heating assembly background wall, comprising a frame 1 and a background plate 2; the frame 1 is an inverted U-shaped frame structure, and the left and right sides of the background plate 2 are fixedly installed on the inner side of the frame 1, respectively, Two storage cavities 4 are symmetrically provided on the left and right sides of the front part of the background plate 2. A number of partitions 12 are fixedly installed inside the storage chamber 4. The partitions 12 divide the interior of the storage chamber 4 into multiple cavities for placing sundries. The background plate 2 is an integrated structure composed of a front panel and a back panel. The specific material of the front panel is silica gel. A disc-shaped heating plate 26 is fixedly installed inside the front panel. The heating plate generates heat and passes through the front The panel radiates the interior of the room to increase the internal temperature of the room; the le...

Embodiment 3

[0036] See Figure 1-4 , A graphene heating assembly background wall, comprising a frame 1 and a background plate 2; the frame 1 is an inverted U-shaped frame structure, and the left and right sides of the background plate 2 are fixedly installed on the inner side of the frame 1, respectively, Two storage cavities 4 are symmetrically provided on the left and right sides of the front part of the background plate 2. A number of partitions 12 are fixedly installed inside the storage chamber 4. The partitions 12 divide the interior of the storage chamber 4 into multiple cavities for placing sundries. The background plate 2 is an integrated structure composed of a front panel and a back panel. The specific material of the front panel is silica gel. A disc-shaped heating plate 26 is fixedly installed inside the front panel. The heating plate generates heat and passes through the front The panel radiates the interior of the room to increase the internal temperature of the room; the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com