Rotary multifunctional valve core

A multi-functional valve and rotary technology, applied in the field of sanitary ware, can solve the problems of complex design, single function and complicated operation of the waterway control part, and achieve the effect of simple structure, diversified functions and easy operation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Any feature disclosed in this specification, unless specifically stated, can be replaced by other alternative features that are equivalent or have similar purposes. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

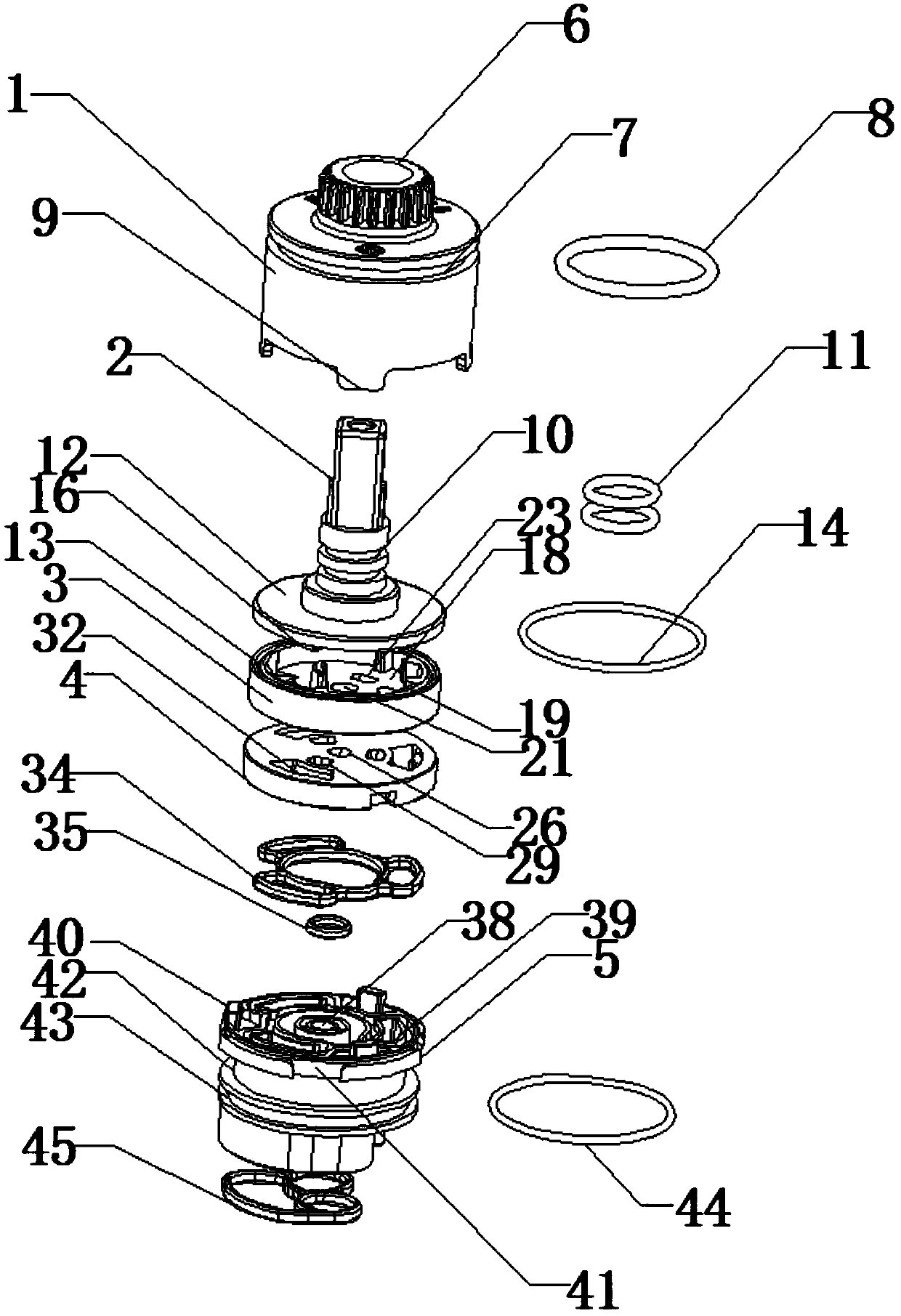

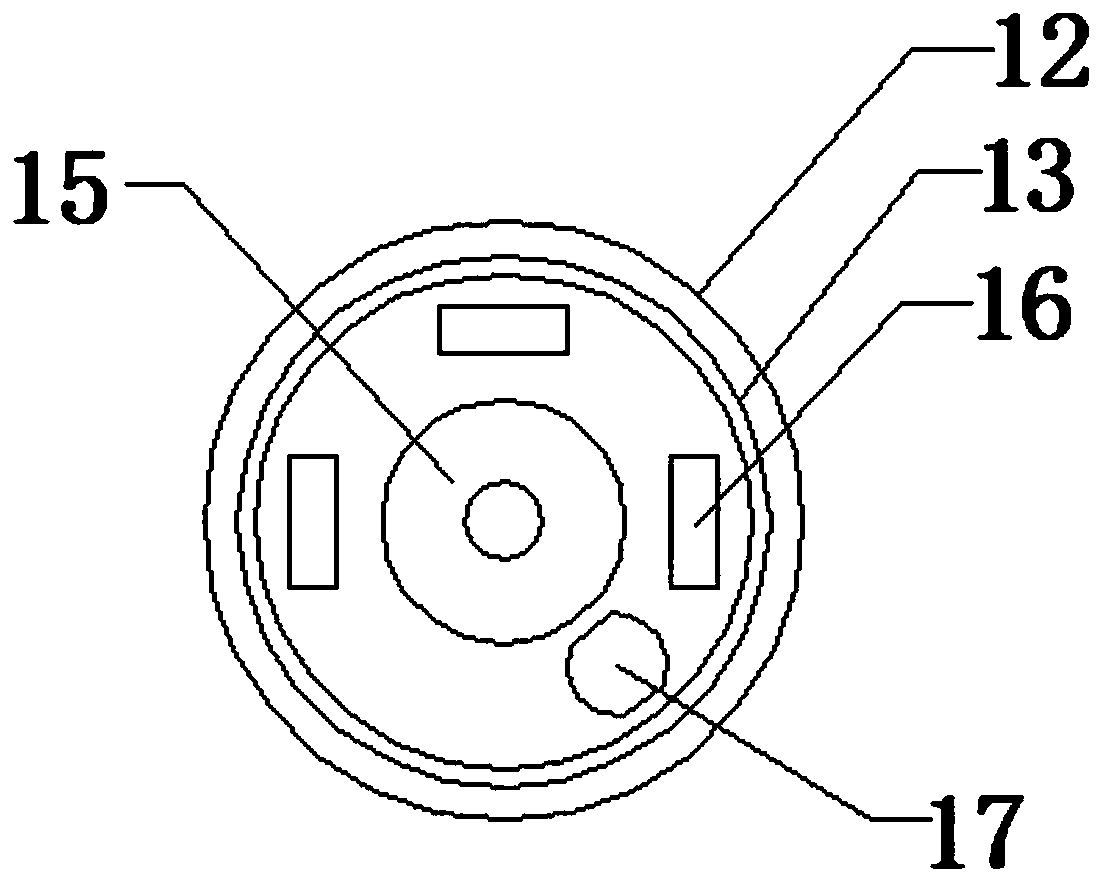

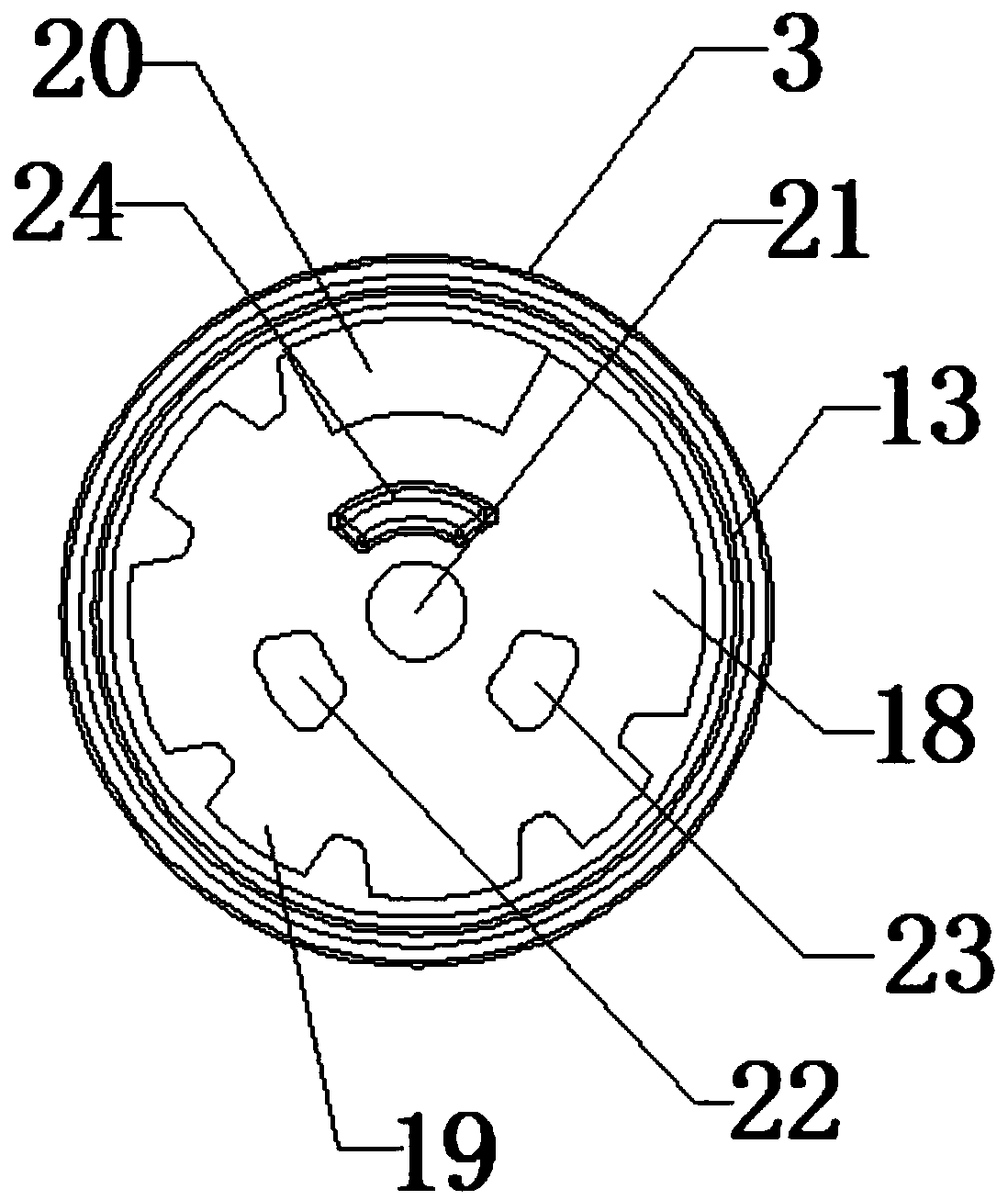

[0024] Such as Figure 1-9A rotary multifunctional valve core shown includes a casing 1, a handle 2, a ceramic moving piece 3, a ceramic static piece 4 and a base 5, and a first ring groove 7 is set inside the top outside of the casing 1, and a first ring groove 7 is arranged on the outside of the first ring A first sealing O-ring 8 is arranged in the groove 7, and two second ring grooves 10 are arranged in sequence on the handle 2, and a second sealing O-ring 11 is arranged in the second ring groove 10, and the top of the ceramic moving piece 3 A third ring groove 13 is arranged inside, a third sealing O-ring 14 is arranged in the third ring groove 13, a fourth ring groove 43 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com