Detection method for total iron in iron ore powder

A detection method and technology for iron ore powder, applied in the direction of electrical excitation analysis, material excitation analysis, etc., can solve the problems of complex and tedious process, long time consumption, and high requirements for chemical analysis skills, so as to avoid the digestion process, the method is simple and fast, and the testing personnel less demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

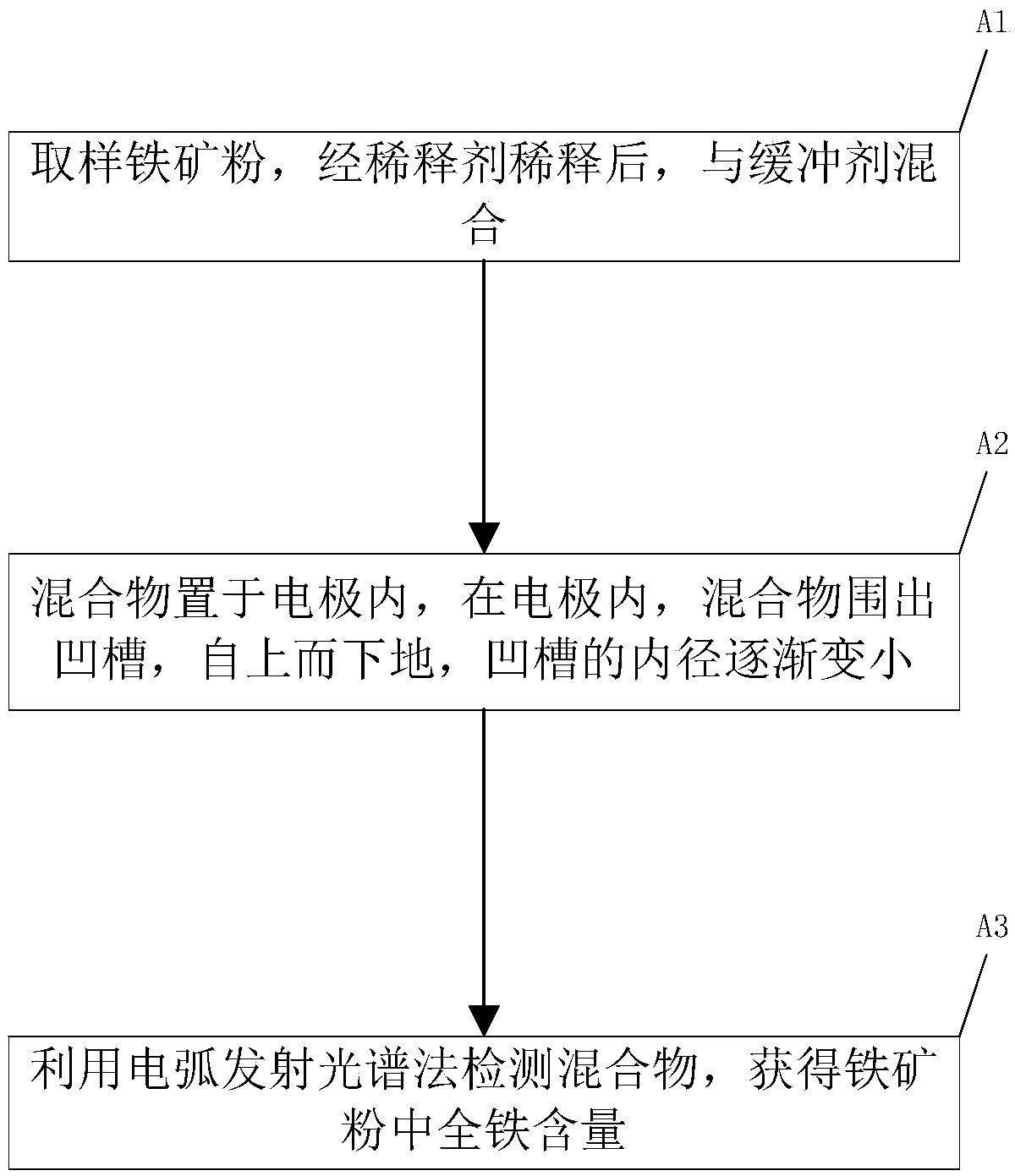

[0019] figure 1 Schematically provides the flow chart of the detection method of total iron in iron ore powder of the embodiment of the present invention, as figure 1 Shown, the detection method of total iron in described iron ore powder may further comprise the steps:

[0020] (A1) Sampling iron ore powder, diluting with a diluent such as tungsten trioxide, dilutes the Fe content in the sample, avoids saturated self-absorption caused by too high Fe spectral intensity, and balances the matrix differences caused by various iron ore matrices, Reduce matrix effect;

[0021] mixed with a buffer (such as a mixture of carbon and lithium carbonate);

[0022] (A2) The mixture is placed in the electrode, and in the electrode, the mixture surrounds a groove, from top to bottom, the inner diameter of the groove is from R 1 change to R 2 , R 2 1 , and R 1 is the inner diameter of the electrode, that is, the thickness of the mixture attached to the inner wall of the electrode increas...

Embodiment 2

[0027] An application example of the method for detecting total iron in iron ore powder according to Embodiment 1 of the present invention.

[0028] In this application example, the diluent is spectrally pure tungsten trioxide, and the buffer is a mixture of 95% carbon and 5% lithium carbonate; WO 3 +C=WC+CO 2 , the WO with low melting and boiling point and easy evaporation 3 Convert to hard-to-evaporate WC, suppress W evaporation, reduce diluent WO 3 Spectral interference; lithium carbonate is used to increase the temperature of the arc flame and maintain the stability of the arc flame; the groove is in the shape of an inverted ball table, and the distance from the bottom of the groove to the top of the graphite electrode That is K = 0.5; use the internal standard method to detect the total iron content

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap