Crystal oscillator lifetime determination method, film thickness measuring device, film forming method, film forming device, and electronic device manufacturing method

A technology of crystal oscillator and determination method, which is applied in semiconductor working life test, measurement device, electric solid device and other directions, can solve the problems of measuring film thickness, reduction of resonance frequency, vibration energy loss of crystal oscillator, etc. , Reduce the increase in production costs, and accurately measure the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, preferred embodiments and examples of the present invention will be described with reference to the drawings. However, the following embodiments and examples are merely illustrative of preferred structures of the present invention, and the scope of the present invention is not limited to these structures. In addition, in the following description, the hardware configuration and software configuration, processing flow, manufacturing conditions, dimensions, materials, shapes, etc. of the device are not intended to limit the scope of the present invention unless otherwise specified.

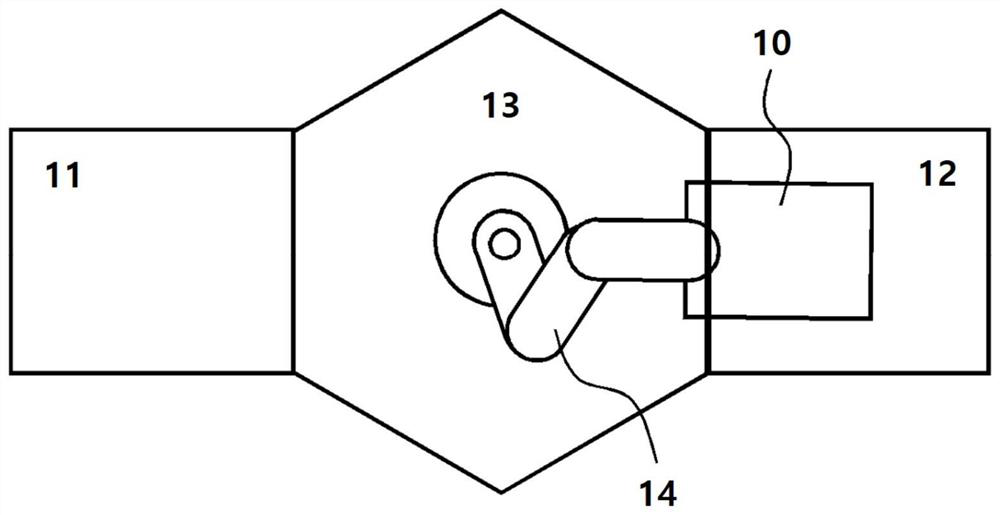

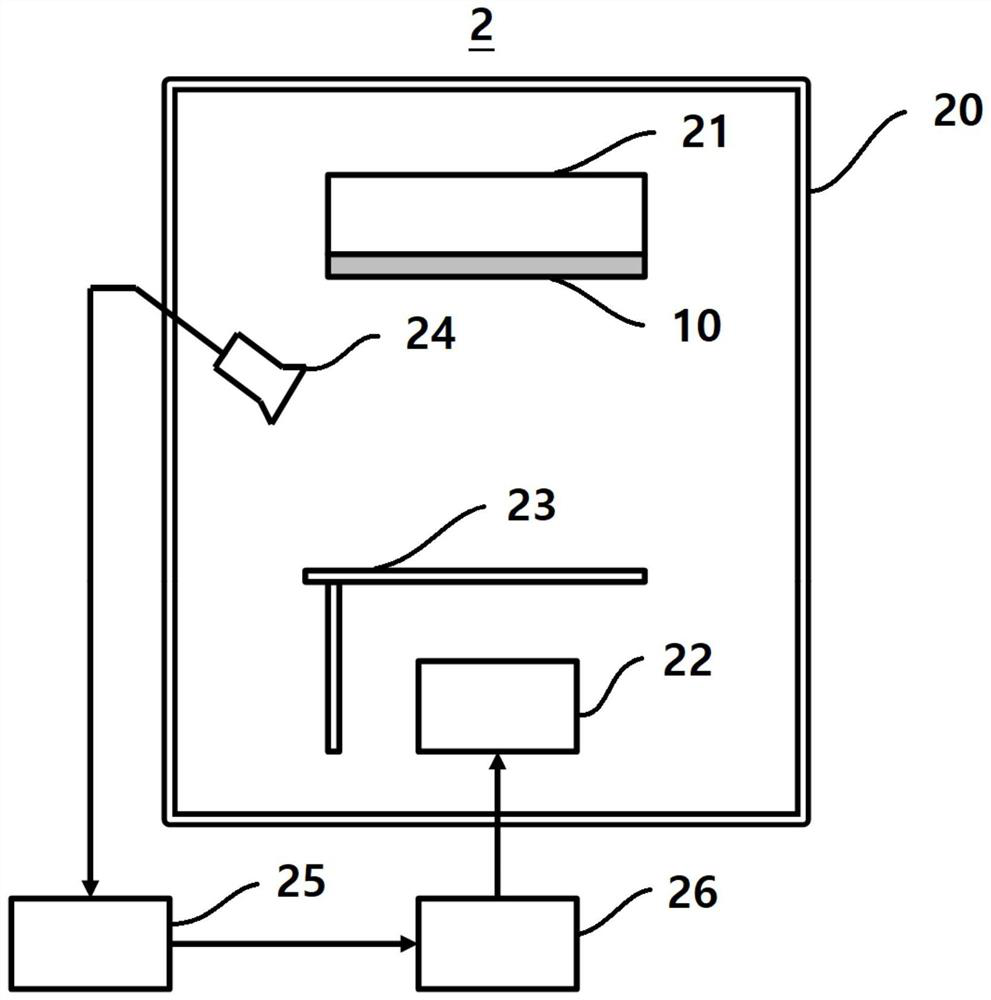

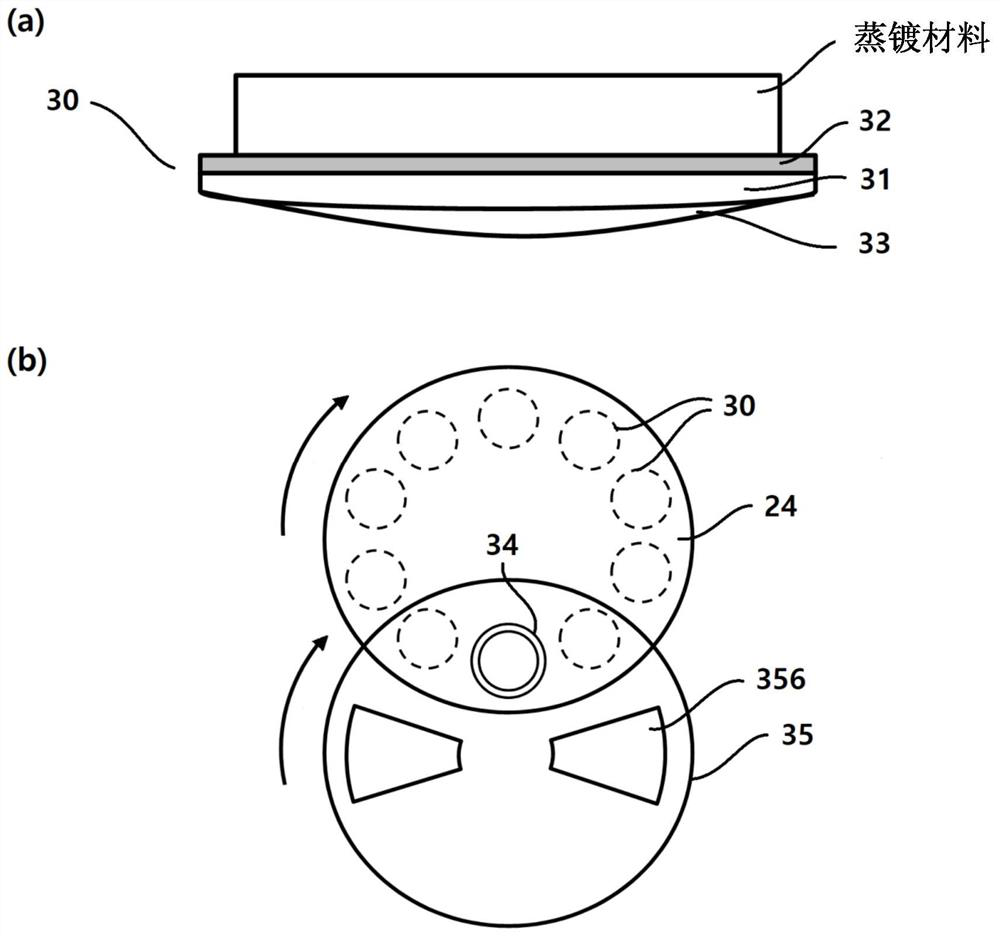

[0026] The present invention relates to a life determination method of a crystal oscillator, a film forming method using the life determination method of a crystal oscillator, a film thickness measuring device, a film forming device including the film thickness measuring device, and an electronic device manufacturing method. It is used to more accurately determine the life of a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com