Layered composite contacts

A composite contact and contact technology, applied in the direction of contact material, contact surface shape/structure, etc., can solve the problems of large errors in the judgment of contact service life, over-repair, and contact life errors, etc. Achieve the effect of achieving accurate condition maintenance, avoiding over-repair or lack of repair, and avoiding data errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

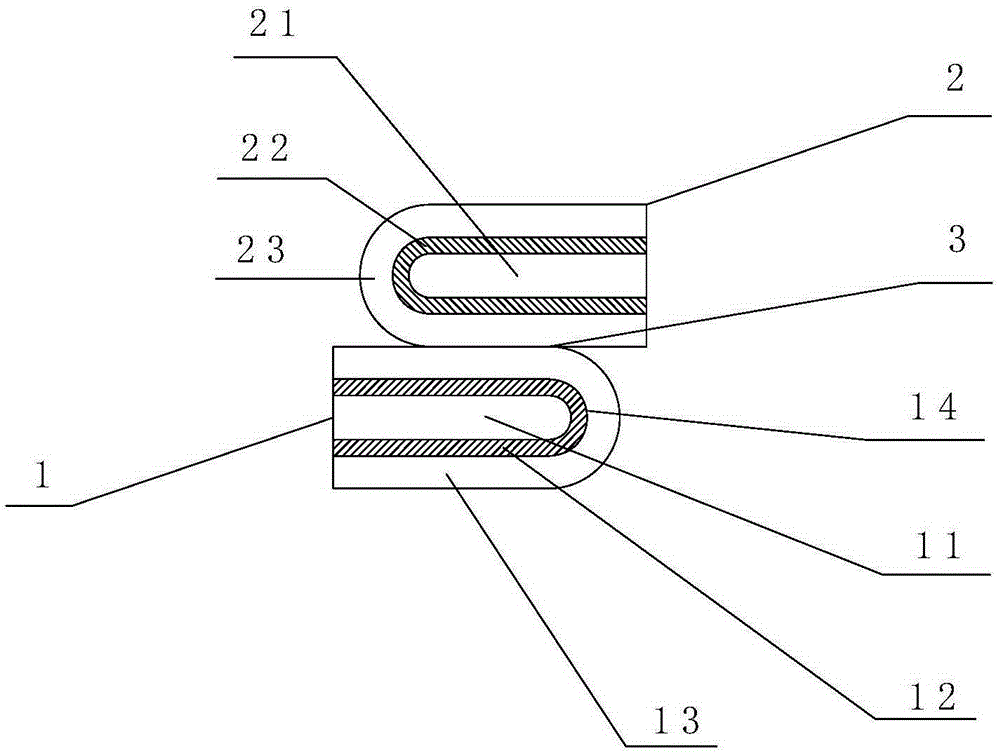

[0016] Attached below figure 1 To further illustrate the present invention, the schematic diagram of the layered composite contact structure of the present invention is as follows figure 1 Shown: The laminated composite contact includes A contact 1 and B contact 2 of the same structure, because the contacts are generally used in pairs, but if the element is a special unipolar, then there can be only one contact. Similarly, if the component has N points, then there will be N or 2N contacts. The A contact 1 includes the A outer layer 13 and the A inner layer 11 and the A identification layer 12 located between the A outer layer 13 and the A inner layer 11, and the B contact 2 includes the B outer layer 23 and the B inner layer 21 and is located at the B The B marking layer 22 between the outer layer 23 and the B inner layer 21; the material of the outer layer and the inner layer of the contact can be the same or different, and when the materials of the outer layer and the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com