High-efficiency optical path folding device and miniaturized high-sensitivity gas sensor

A gas sensor and high-sensitivity technology, applied in optical components, optics, instruments, etc., can solve the problems of short optical path, large volume, unstable optical path structure, etc., and achieve the effect of long optical path, small volume, and stable optical path structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

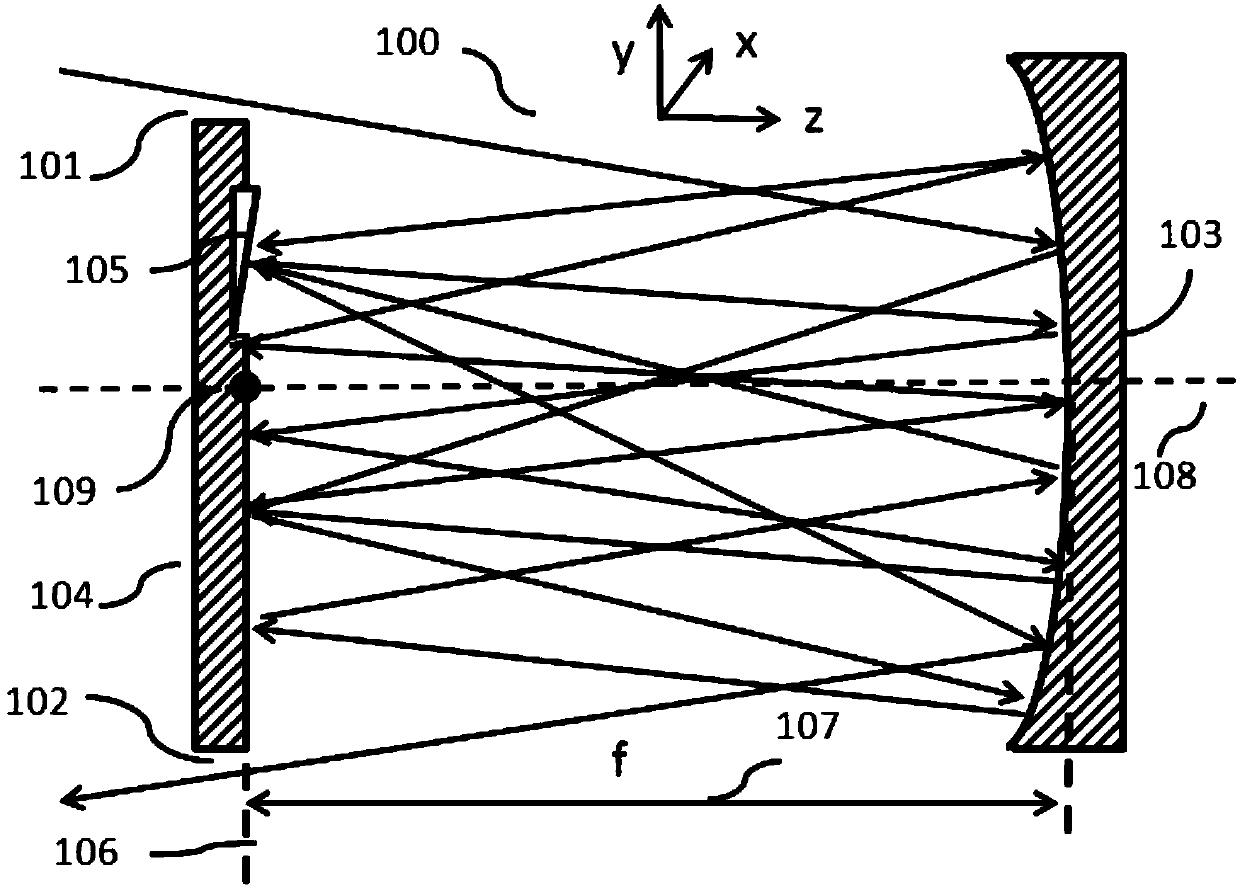

[0058] Such as figure 1 As shown, the present application provides a high-efficiency optical path folding device 100, including:

[0059] an input port 101 for inputting a light beam;

[0060] an output end 102 for outputting light beams, the input end 101 is set separately from the output end 102;

[0061] a main plane mirror 104;

[0062] A concave reflector 103 has a focal plane 106, and the distance 107 from the focal plane 106 to the concave reflector 103 is the focal length f of the concave reflector 103; the focal plane 106 has an origin 109, and the origin 109 is the main plane reflector 104 and the concave surface The intersection of the optical axis 108 of the optical system composed of reflectors 103 on the focal plane 106;

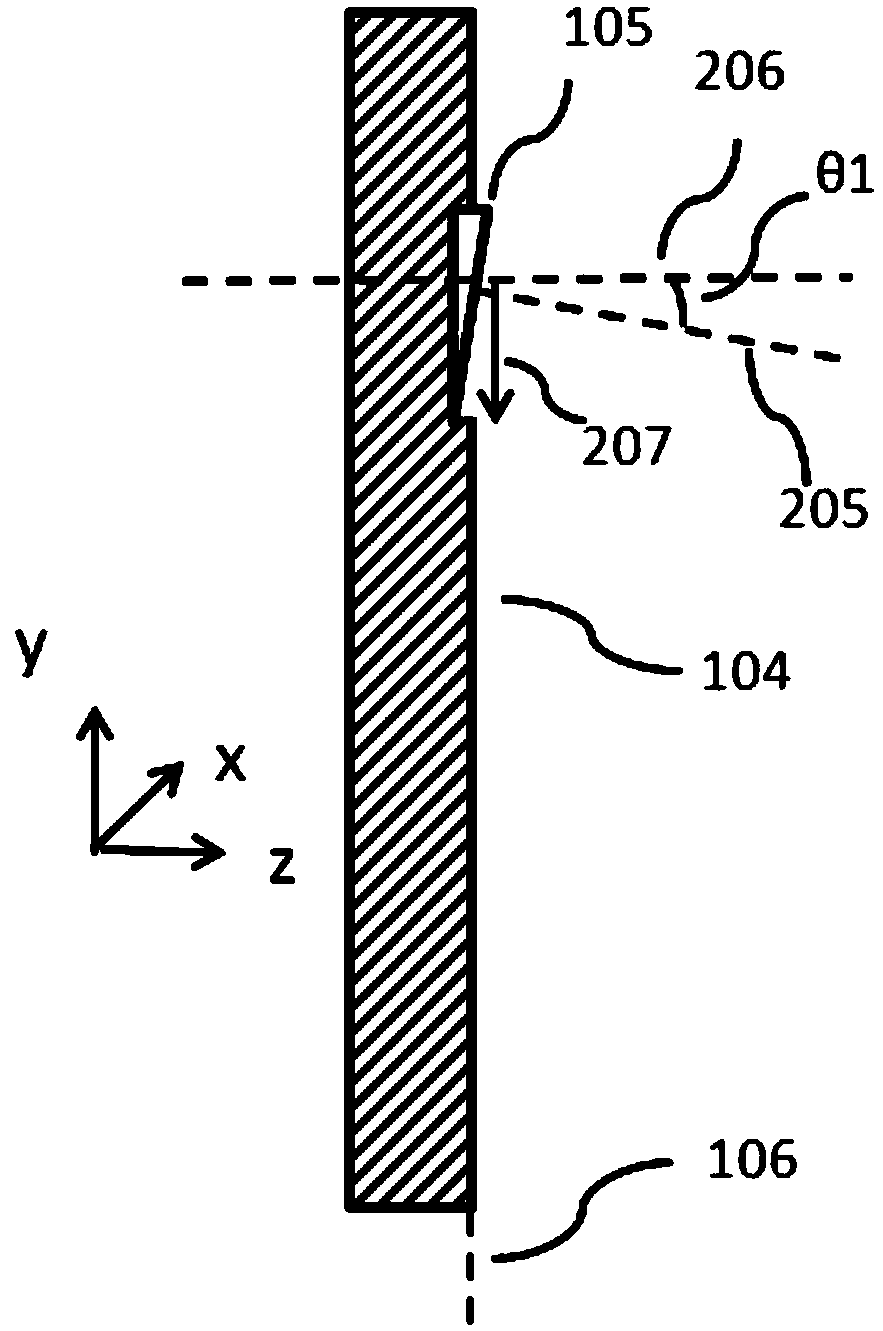

[0063] A tilting mirror 105 is a plane mirror whose area is less than the main plane mirror 104, and the tilt angle between the normal of the tilt mirror 105 and the normal of the main plane mirror 104 is θ1; the tilt angle θ1 is not zero; ...

Embodiment 2

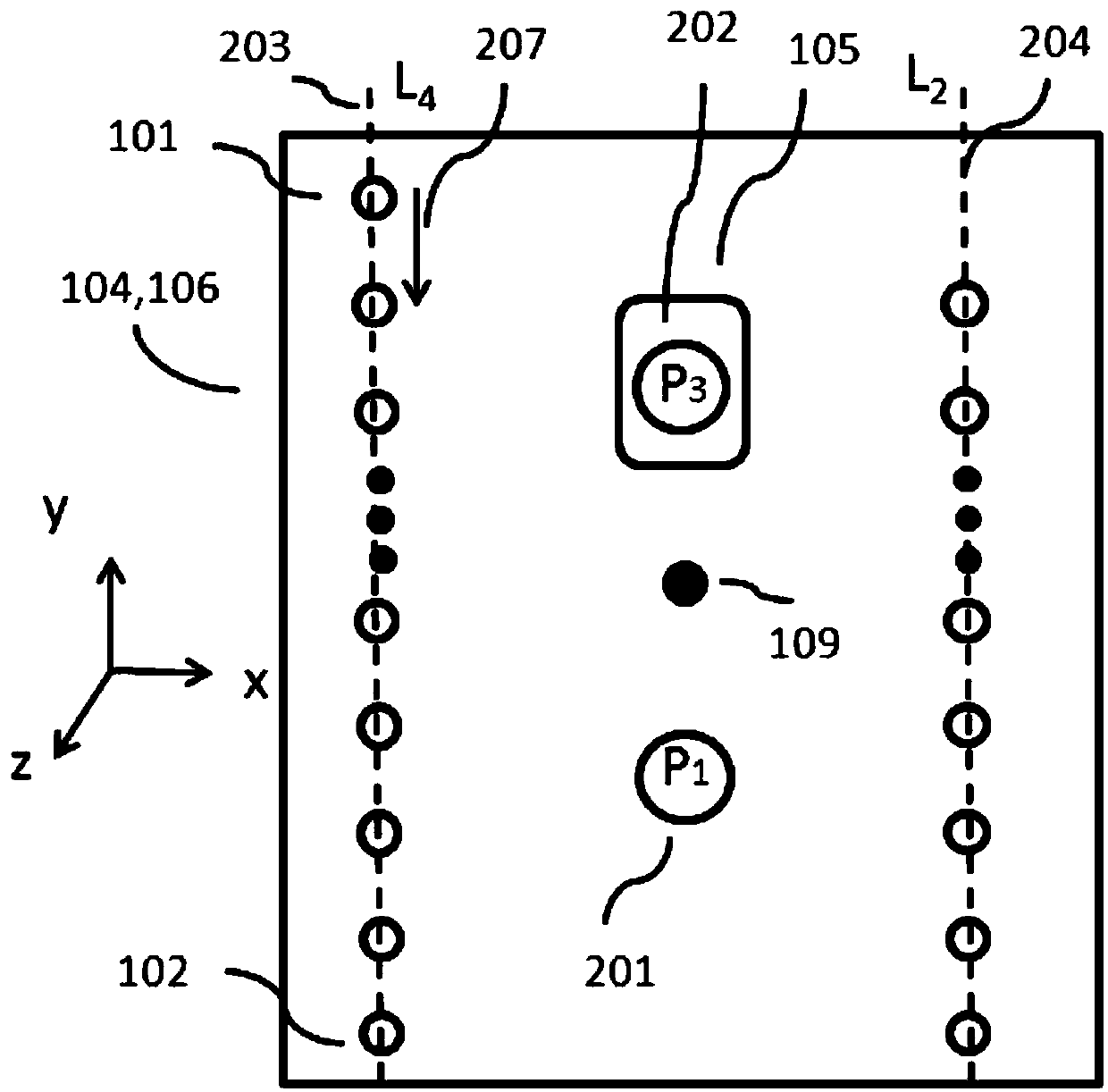

[0090] Such as Figure 4 As shown, this embodiment provides a high-efficiency optical path folding device 200, which, on the basis of Embodiment 1, further includes:

[0091] A side mirror 110 is a plane mirror whose area is smaller than the main plane mirror 104, and the inclination angle between the normal of the side mirror 110 and the normal of the main plane mirror 104 is θ2; the inclination angle θ2 is not zero;

[0092] The incident surface of the input end 101, the main plane reflector 104 and the inclined reflector 105 are coplanar and located at the focal plane 106 of the concave reflector 103;

[0093] The light beam is input from the input end 101, after multiple reflections between the concave reflector 103, the main plane reflector 104 and the inclined reflector 105, it is reflected by the side reflector 110 to the incident end of the output end 102, and from the output end 102 output.

[0094] To avoid the side reflector 110 on the L 2 or L 4 The interferen...

Embodiment 3

[0098] Such as Figure 5 and Figure 6 As shown, this embodiment provides a miniaturized high-sensitivity gas sensor 300, including the high-efficiency optical path folding device 100 in the first embodiment or the high-efficiency optical path folding device 200 in the second embodiment, and the high-efficiency optical path folding device 100 or 200 Set in the gas chamber space where the gas to be tested is located;

[0099] The miniaturized high-sensitivity gas sensor 300 also includes:

[0100] A laser 301, located at the incident end of the input end 101, for providing the light beam input by the input end 101;

[0101] A detector 302, located at the output end of the output end 102, is used to receive and detect the light beam output from the output end 102 to obtain the gas concentration test data of the gas to be tested.

[0102] Figure 5 3 exemplarily shows the situation that the miniaturized high-sensitivity gas sensor 300 includes the high-efficiency optical path...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com