Magnetic metal and carbon composite wave-absorbing material derived from layered double magnetic metal hydroxides and preparation method of magnetic metal and carbon composite wave-absorbing material

A magnetic metal and hydroxide technology, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve the problem of non-magnetism of the composite, achieve the effects of reducing weight and density, improving interface polarization, and excellent wave-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of a layered double magnetic metal hydroxide-derived magnetic metal@carbon composite wave absorbing material, comprising the following steps:

[0033] 1) Take 0.6058g Fe (NO 3 ) 3 ·9H 2 O, 0.8724g Ni (NO 3 ) 2 ·6H 2 O, 0.4830g CH 4 N 2 O and 0.54g C 6 H 12 O 6 Dissolved in 50ml of deionized water in turn, magnetically stirred for 30min and mixed uniformly, the mixed solution was transferred to a 100ml high pressure reactor, hydrothermally reacted at 180°C for 12h, and the reaction product was vacuum filtered to obtain a dark brown precipitate. The brown precipitate was washed three times with deionized water and twice with absolute ethanol, and then the precipitate was dried in an oven at 60 °C for 12 h to obtain FeNi hydroxide (FeNi-LDH) precursor;

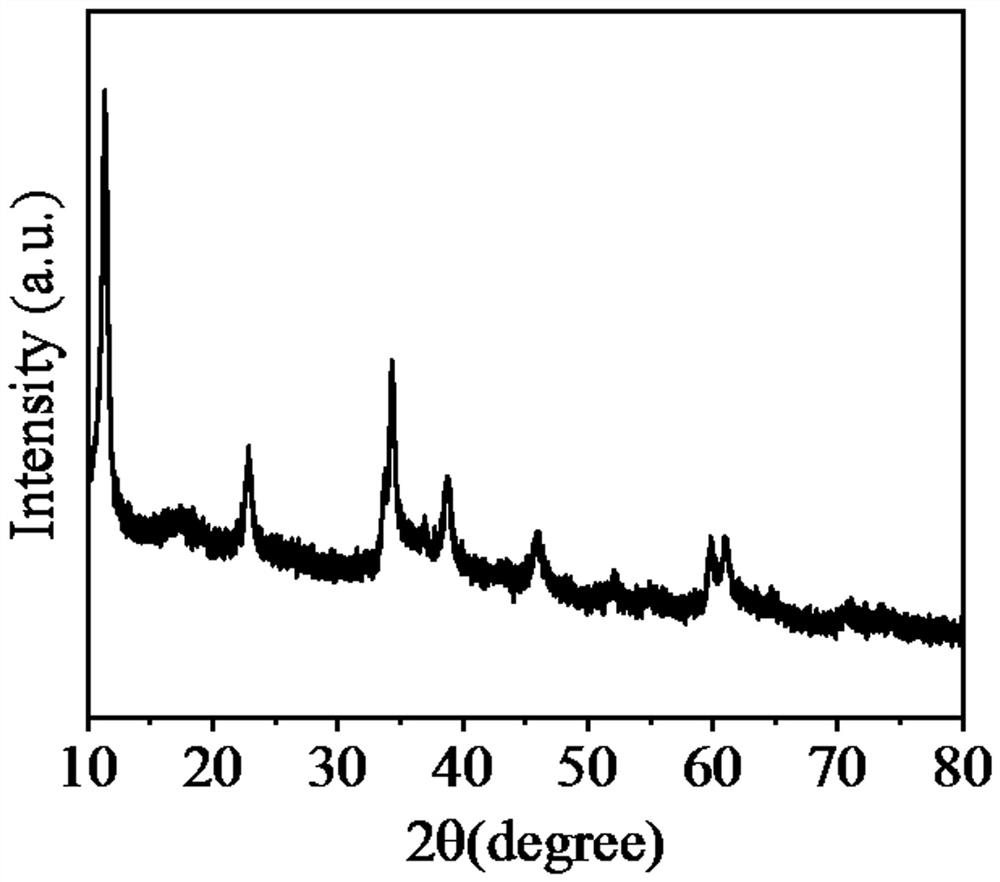

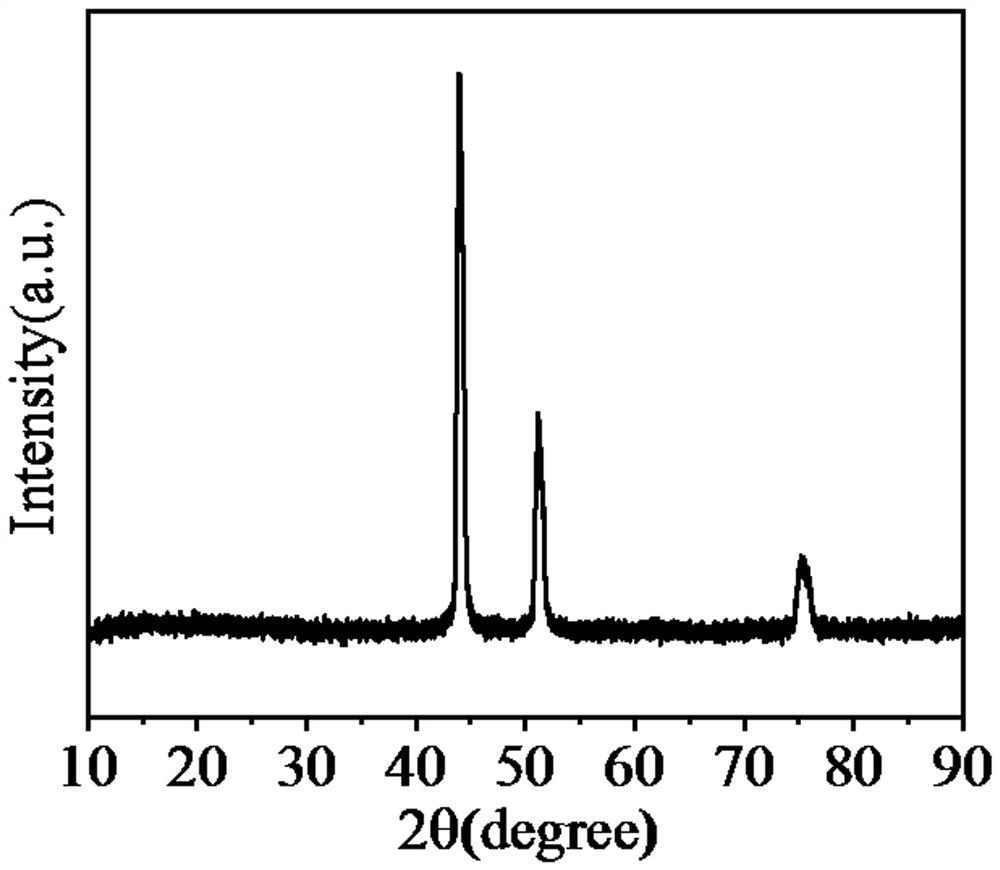

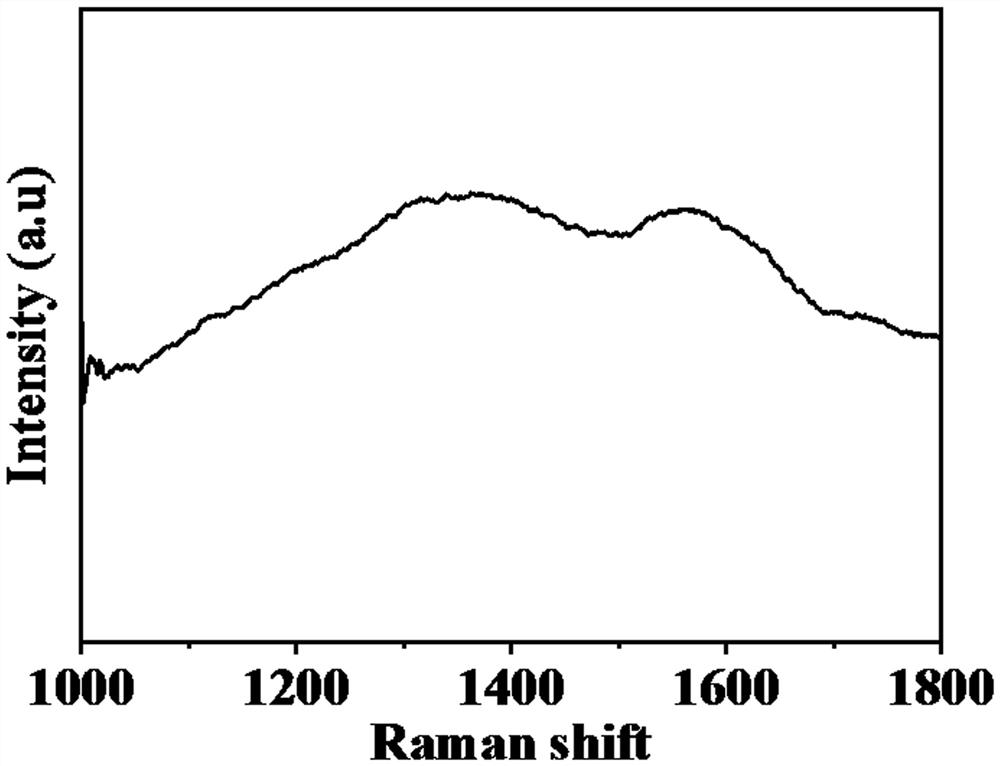

[0034] 2) The FeNi-LDH precursor obtained in step 1) was placed in a tube furnace, passed into a protective atmosphere of Ar, and sintered at 700 °C for 2 h to finally obtain a three-dimensio...

Embodiment 2

[0036] A preparation method of a layered double magnetic metal hydroxide-derived magnetic metal@carbon composite wave absorbing material, comprising the following steps:

[0037] 1) Take 0.6058g Fe (NO 3 ) 3 ·9H 2 O, 0.8724g Ni (NO 3 ) 2 ·6H 2 O, 0.4830g CH 4 N 2 O and 0.54g C 6 H 12 O 6 Dissolved in 50ml of deionized water in turn, magnetically stirred for 30min and mixed evenly, then the mixed solution was transferred to a 100ml high pressure reactor, hydrothermally reacted at 180°C for 12h, and the reaction product was subjected to vacuum filtration to obtain a dark brown precipitate, dark brown The precipitate was washed three times with deionized water and twice with anhydrous ethanol, and then the precipitate was placed in an oven at 60°C for 12 hours and dried to obtain FeNi hydroxide (FeNi-LDH) precursor;

[0038] 2) The FeNi-LDH precursor obtained in step 1) was placed in a tube furnace, passed into a protective atmosphere of Ar, and sintered at 800 °C for 2...

Embodiment 3

[0040] A preparation method of a layered double magnetic metal hydroxide-derived magnetic metal@carbon composite wave absorbing material, comprising the following steps:

[0041] 1) Take 0.6058g Fe (NO 3 ) 3 ·9H 2 O, 0.8730g Co (NO 3 ) 2 ·6H 2 O, 0.4830g CH 4 N 2 O and 0.54g C 6 H 12 O 6Dissolved in 50ml of deionized water in turn, magnetically stirred for 30min and mixed uniformly, the mixed solution was transferred to a 100ml high pressure reactor, hydrothermally reacted at 180 ° C for 12h, the reaction product was subjected to vacuum filtration to obtain a dark brown precipitate, dark brown The precipitate was washed three times with deionized water and twice with absolute ethanol, and then the precipitate was dried in an oven at 60 °C for 12 h to obtain FeCo hydroxide (FeCo-LDH) precursor;

[0042] 2) The FeCo-LDH precursor obtained in step 1) was placed in a tube furnace, poured into a protective atmosphere of Ar, sintered at 700 °C for 2 h, and finally a three-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com