A T-shaped active sensing system and method applied to long material stacking batch number recognition

A technology of perception system and batch number, applied in the direction of data processing applications, collaborative operation devices, instruments, etc., can solve problems such as long storage time, long material stacking management can not accurately reflect inventory and batches, enterprise losses, etc. , to reduce the cost of human resources, improve the level of automation and intelligent management, and achieve the effect of precise management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

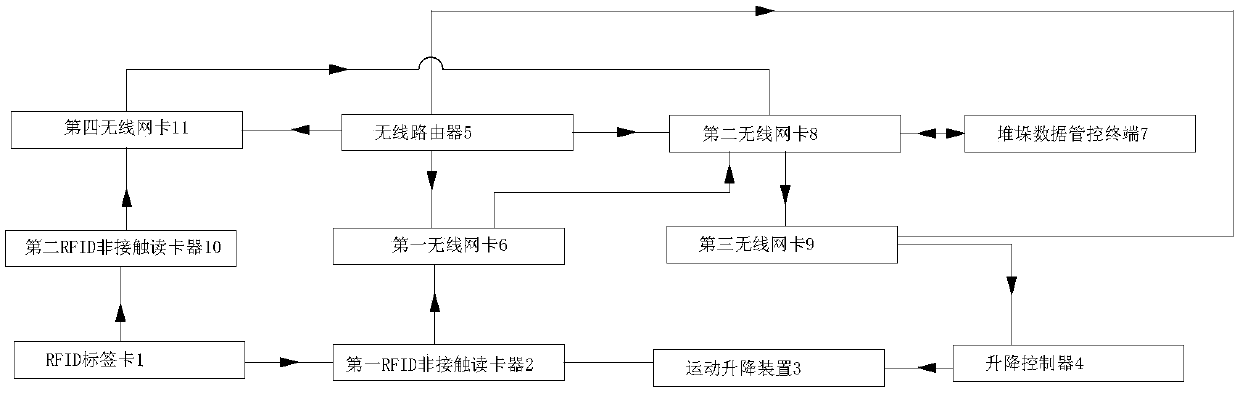

[0046] Such as figure 1As shown, the T-type active sensing system applied to long product stacking batch number identification is characterized in that it includes an RFID tag card 1, a first RFID non-contact card reader 2, a motion lifting device 3, a lifting controller 4, Wireless router 5, first wireless network card 6, stacking data control terminal 7, second wireless network card 8, third wireless network card 9, second RFID non-contact card reader 10, fourth wireless network card 11;

[0047] The batch information of each bundle of materials is stored in the RFID tag 1, and is fixed at one end of each bundle of materials;

[0048] The first RFID non-contact card reader 2 is connected with the first wireless network card 6;

[0049] The stacking data control terminal 7 is connected with the second wireless network card 8;

[0050] The lifting controller 4 is connected with the third wireless network card 9;

[0051] The second RFID non-contact card reader 10 is connect...

Embodiment 2

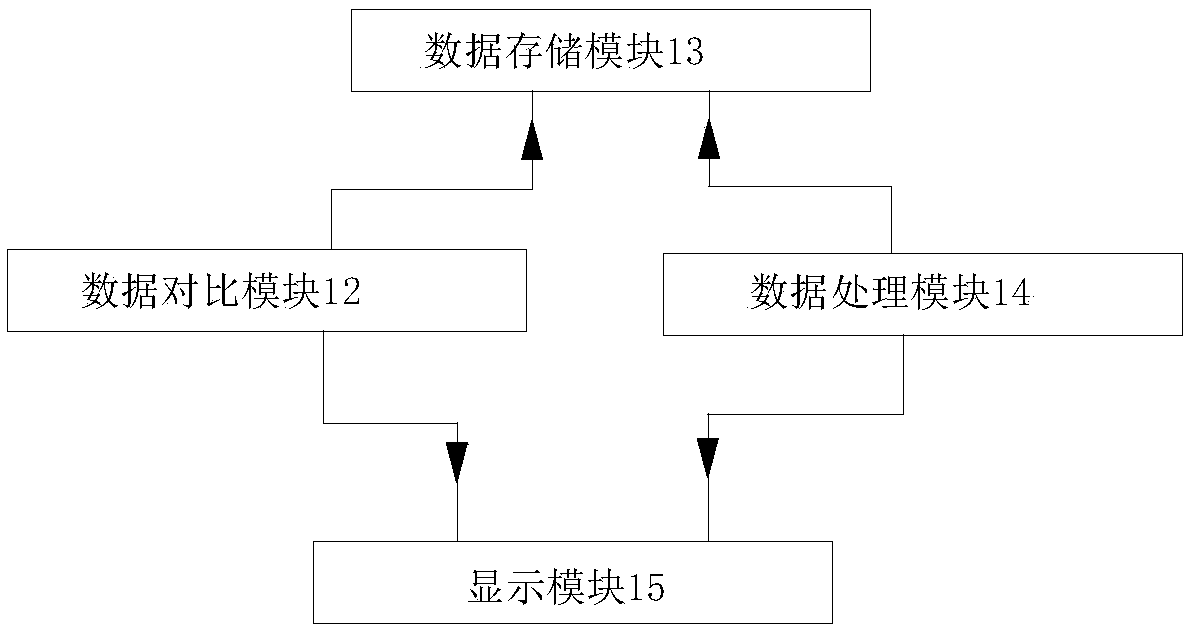

[0069] Such as figure 1 and figure 2 As shown, the T-type active sensing system applied to long product stacking batch number identification is characterized in that it includes an RFID tag card 1, a first RFID non-contact card reader 2, a motion lifting device 3, a lifting controller 4, Wireless router 5, first wireless network card 6, stacking data control terminal 7, second wireless network card 8, third wireless network card 9, second RFID non-contact card reader 10, fourth wireless network card 11;

[0070] The batch information of each bundle of materials is stored in the RFID tag 1, and is fixed at one end of each bundle of materials;

[0071] The first RFID non-contact card reader 2 is connected with the first wireless network card 6;

[0072] The stacking data control terminal 7 is connected with the second wireless network card 8;

[0073] The lifting controller 4 is connected with the third wireless network card 9;

[0074] The second RFID non-contact card read...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com