Solar battery back structure design

A solar cell and backside structure technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problem of increasing the light-receiving area of the battery, and achieve the effect of flexible and adjustable solder joint design, reduction of the front-side light-receiving area, and improvement of failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

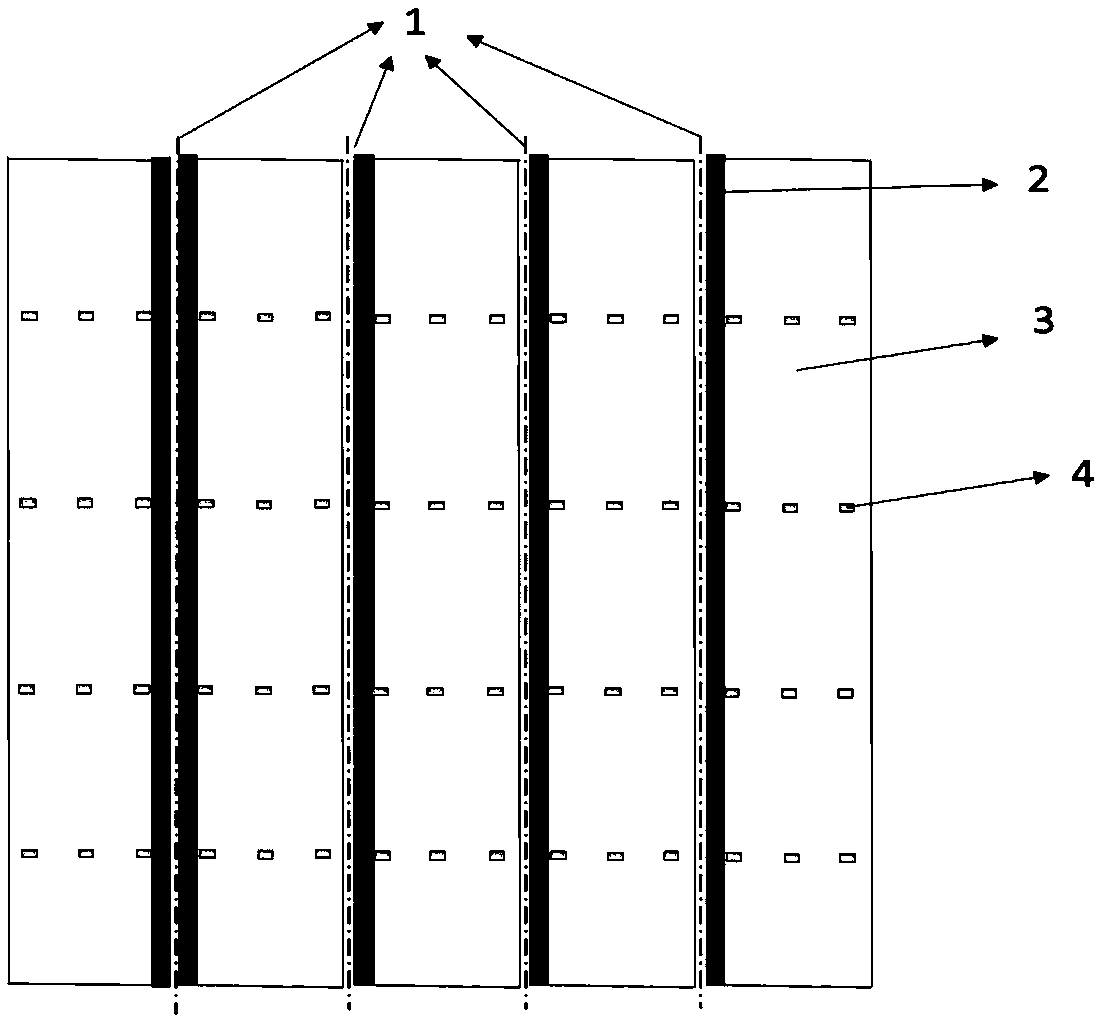

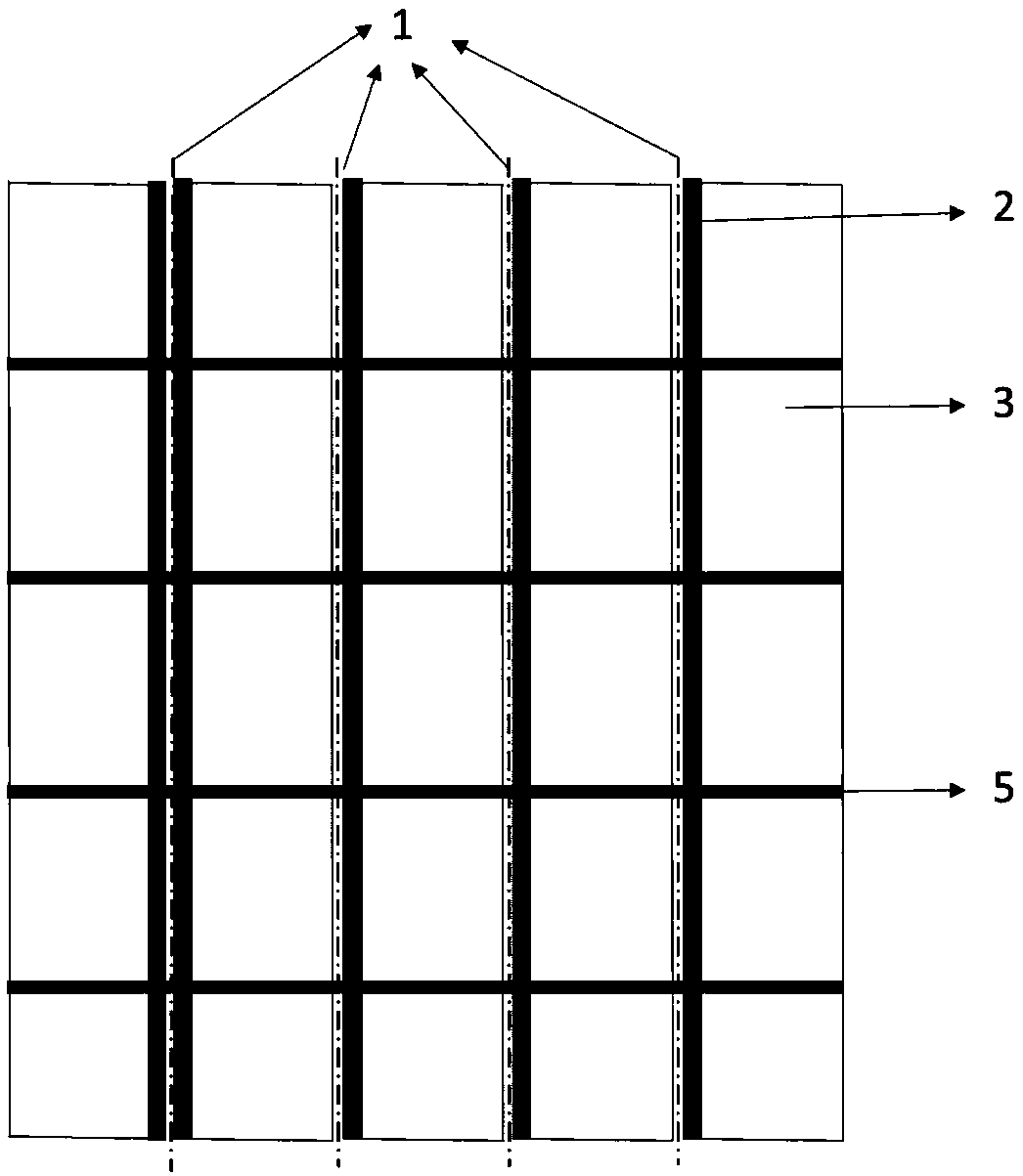

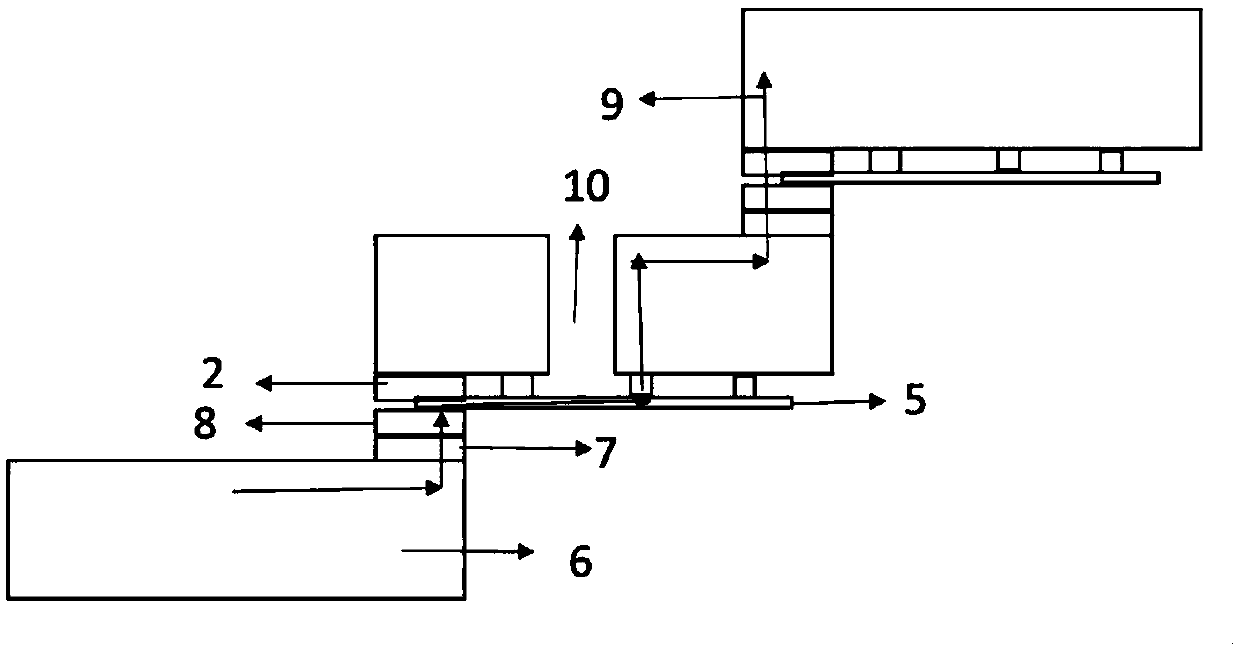

[0024] Such as Figure 1-3 As shown, a solar cell back structure design of the present invention includes a back cell 3, and the back cell 3 includes a plurality of cut cell slices 6, in order to distinguish the positions between adjacent cell slices 6 more clearly. Laser cutting marking lines 1 are marked between the adjacent battery sheets 6, vertical back electrodes 2 are provided on the left side of the battery sheet 6, and vertical positive electrodes 7 are provided on the right side of the battery sheet 6, so Conductive glue 8 is provided on the positive electrode 7 on the front side of the rear battery sheet 6 in the adjacent battery sheet 6 of the back battery 3, and the positive electrode 7 of the rear battery sheet 6 is electrically connected to the back electrode 2 of the front battery sheet 6 through the conductive glue 8. connection, the left and right shingles of adjacent battery sheets 6 are electrically connected, and the battery sheet 6 is provided with a plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com