A method of manufacturing pole piece coil material

A production method and coil material technology, which is applied in the direction of electrode manufacturing, coating, and liquid coating device on the surface, etc., can solve the problems of high cost, easy dislocation of pole pieces, low efficiency, etc., and achieve cost reduction and solvent volume reduction , the effect of increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

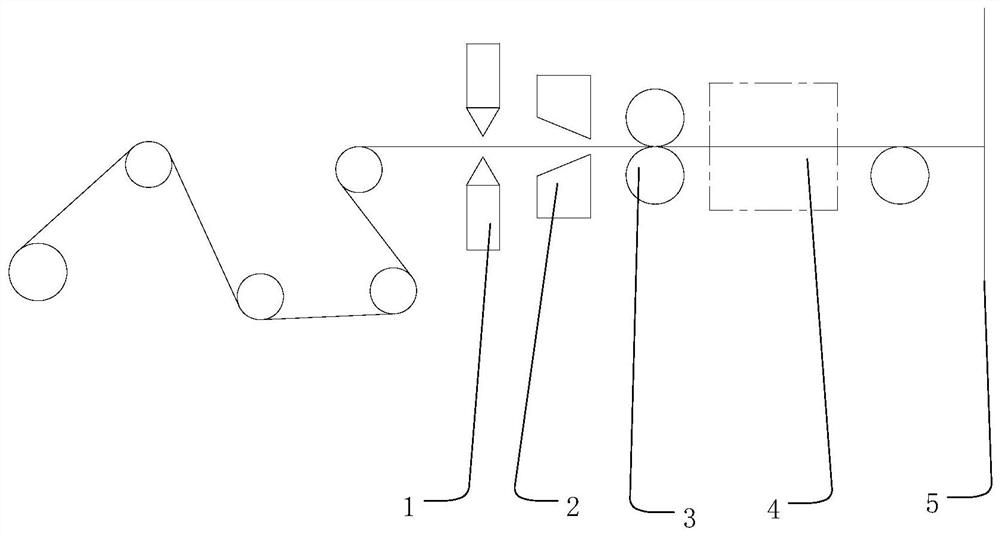

[0029] The present invention is described below based on the embodiments, and those skilled in the art should understand that the drawings provided here are for the purpose of illustration, and the drawings are not necessarily drawn to scale.

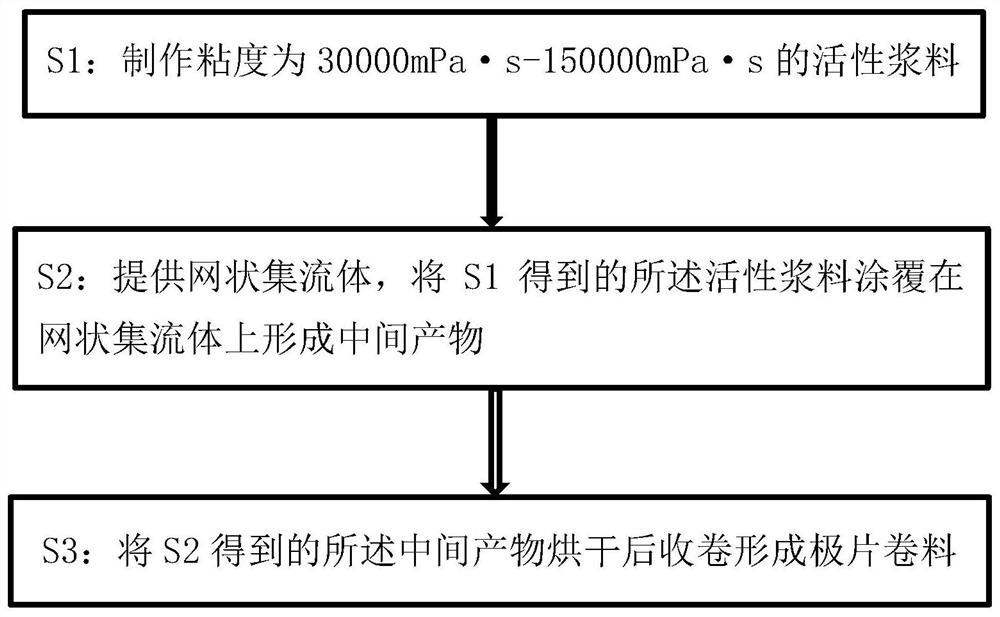

[0030] Unless the context clearly requires, throughout the specification and claims, "comprises", "comprises" and similar words should be interpreted in an inclusive sense rather than an exclusive or exhaustive meaning; that is, "including but not limited to" meaning. refer to figure 1 As shown, the present invention provides a kind of pole sheet coil material manufacturing method, and it comprises the steps:

[0031] S1: Make an active slurry with a viscosity of 30000mPa·s-150000mPa·s;

[0032] S2: providing a mesh collector, coating the active slurry obtained in S1 on the mesh collector to form an intermediate product;

[0033] S3: Drying the intermediate product obtained in S2 and winding it to form a pole sheet coil.

[0034] Sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com