Peanut harvesting device

A technology for peanut harvesting and peanuts, which is applied in the direction of digging harvesters, harvesters, agricultural machinery and tools, etc., can solve the problems of no way to collect peanuts, inconvenient cleaning, peanuts falling, etc., so as to reduce the amount of scattering and increase production rate and the effect of guaranteeing completeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

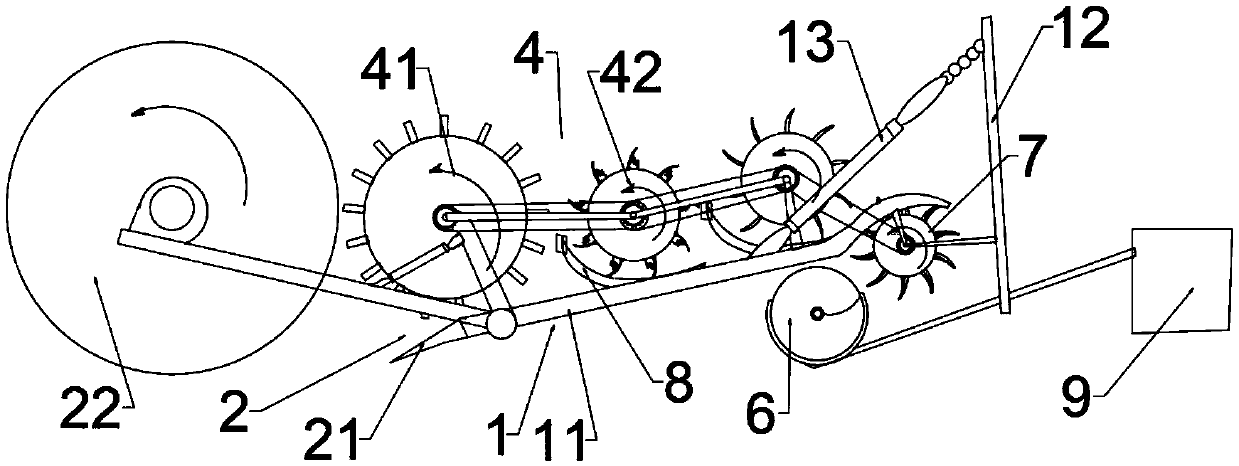

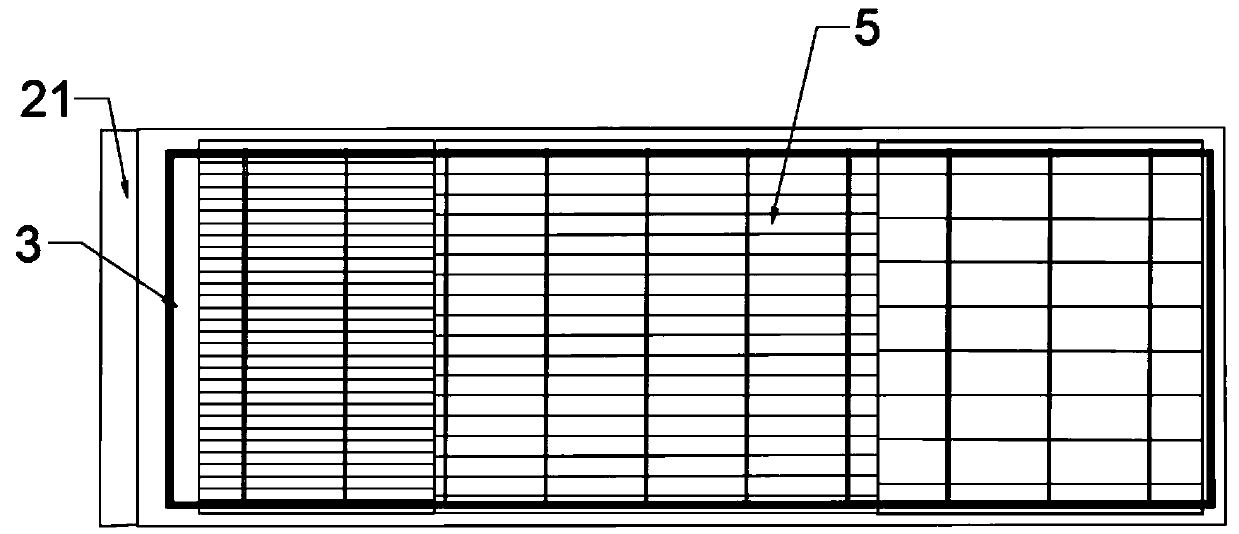

[0053] Such as Figure 1-2 As shown, a peanut harvesting device provided by the present invention includes a frame 1, and also includes an excavating assembly 2, a conveying mechanism 3, a separating assembly 4, a screening mechanism 5, and a peanut collecting mechanism arranged on the frame 1. 6 and power components; the digging assembly 2 is used to dig up peanut plants and soil together; the digging assembly 2 is connected to the input end of the screening mechanism 5; the separation assembly 4 is located on the upper side of the screening mechanism 5 , the separation assembly 4 is used to separate the peanut from the root of the peanut plant; the screening mechanism 5 at least includes a soil screening part 51 distributed along the conveying direction and a peanut and branch screening part 53; the conveying surface of the conveying mechanism 3 Set close to the top of the screening surface of the screening mechanism 5, the conveying mechanism 3 transports the peanuts separa...

Embodiment 2

[0055] Take the forward direction of the peanut harvesting device as the front, and the direction away from the forward direction as the rear.

[0056] Such as Figure 3-5 As shown, on the basis of Embodiment 1, the digging assembly 2 is located at the front of the peanut harvesting device, and the conveying mechanism 3 is located at the top of the screening section. The peanut digging assembly 2 includes a digging shovel 21, a pressing roller 22 located at the front of the contact point between the digging shovel 21 and the ground, and the pressing roller 22 is connected to the frame 1 through a support rod; the two ends of the support rod They are respectively connected to the rotating shaft of the pressure roller drum 22 and the frame 1 in rotation; between the support rod and the first fixed rod fixed on the frame 1, there is an elastic part for adjusting the roller that can be used to adjust the depth of the digging shovel 21 into the soil. The screening mechanism 5 incl...

Embodiment 3

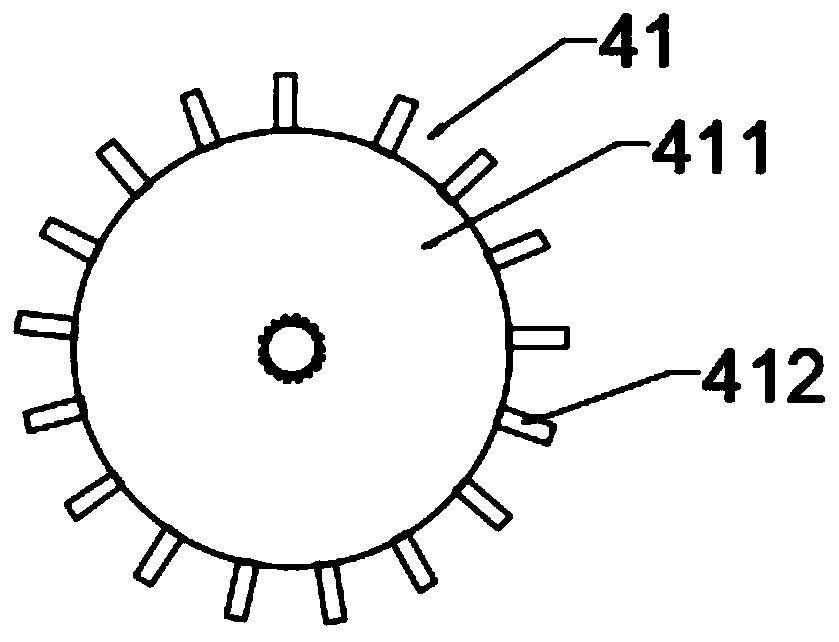

[0060] Such as Figure 6 , 7As shown, on the basis of Example 2, the fruit-picking mechanism 42 includes a first fruit-picking cylinder 421 and a second fruit-picking cylinder 422; The curved tooth 42122 is bent towards the elastic part 42121 on one side; one end of the curved tooth 42122 is connected to the drum body 4211 in rotation, and the other end is bent in the opposite direction of the rotation of the drum body 4211; one end of the elastic part 42121 is fixed to the curved tooth 42122 The other end is fixedly connected to the roller body 4211; the roller body 4211 is also provided with a barrier 4214 for preventing the curved tooth 42122 from rotating to the side away from the elastic part 42121;

[0061] The curved tooth portion 4212 of the second fruit picking cylinder 422 has the same structure as the curved tooth portion 4212 of the first fruit picking cylinder 421; or, the curved tooth portion 4212 of the second fruit picking cylinder 422 is only a curved tooth p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap