Refrigerating cylinder, ice cream machine comprising refrigerating cylinder, and manufacturing process of refrigerating cylinder

An ice cream machine and technology of production process, applied in cylinders, frozen sweets, mechanical equipment, etc., can solve the problems of poor refrigeration effect, uncontrollable temperature, and failure to achieve sterilization and disinfection, so as to ensure the taste and high heat transfer efficiency. Even heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

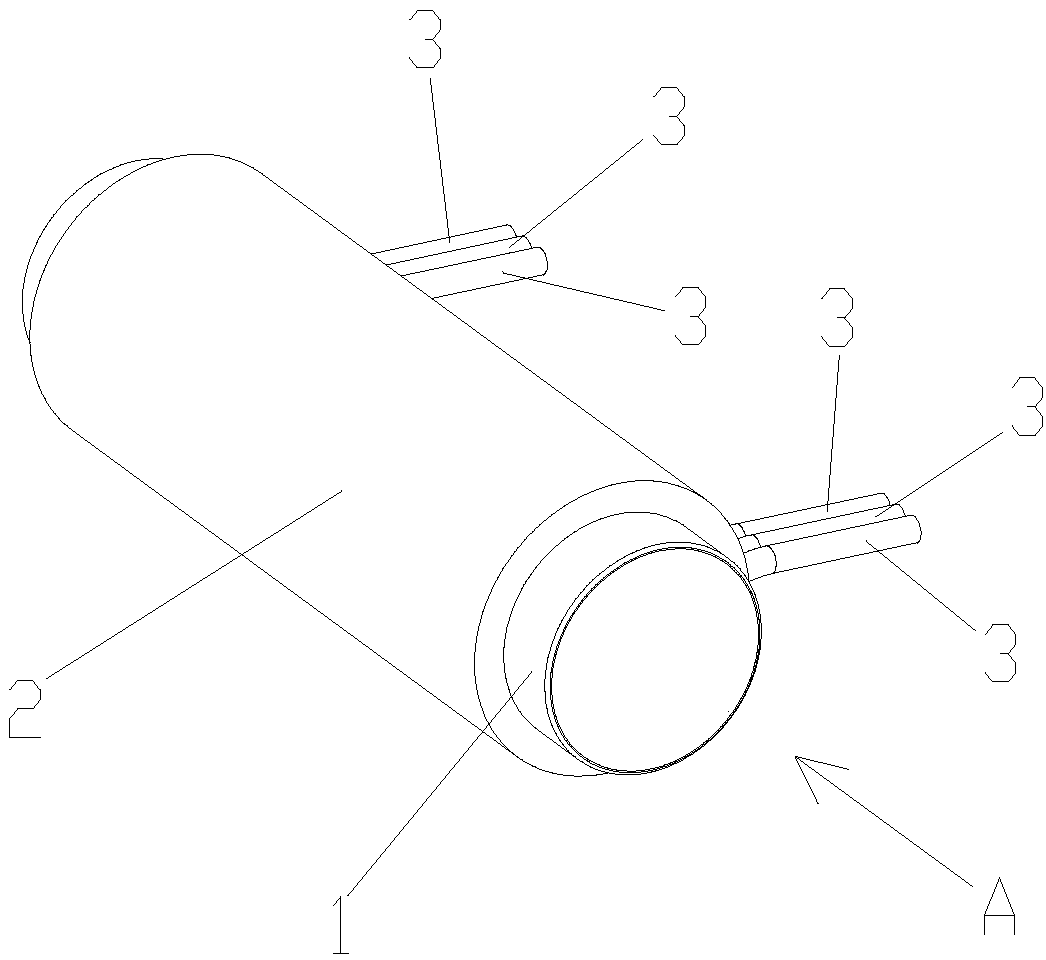

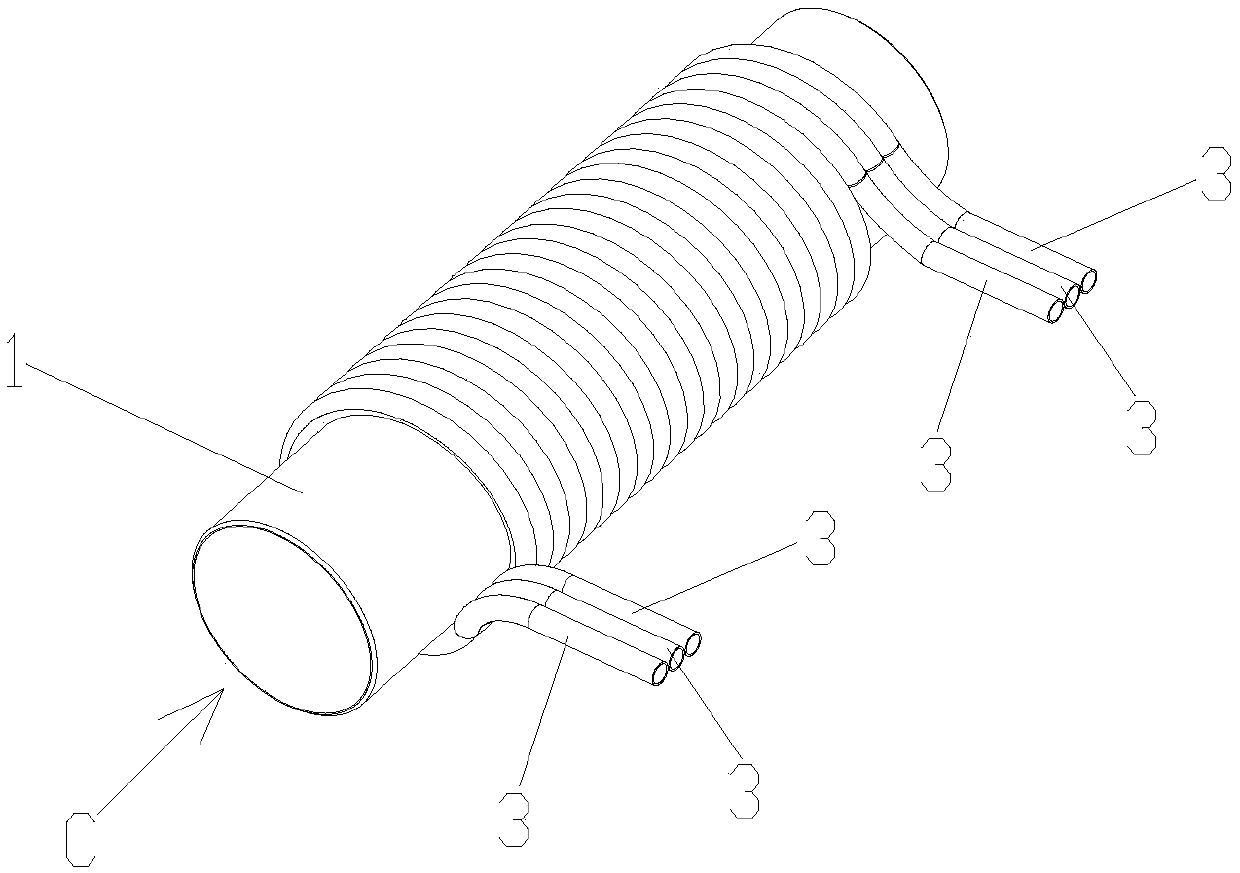

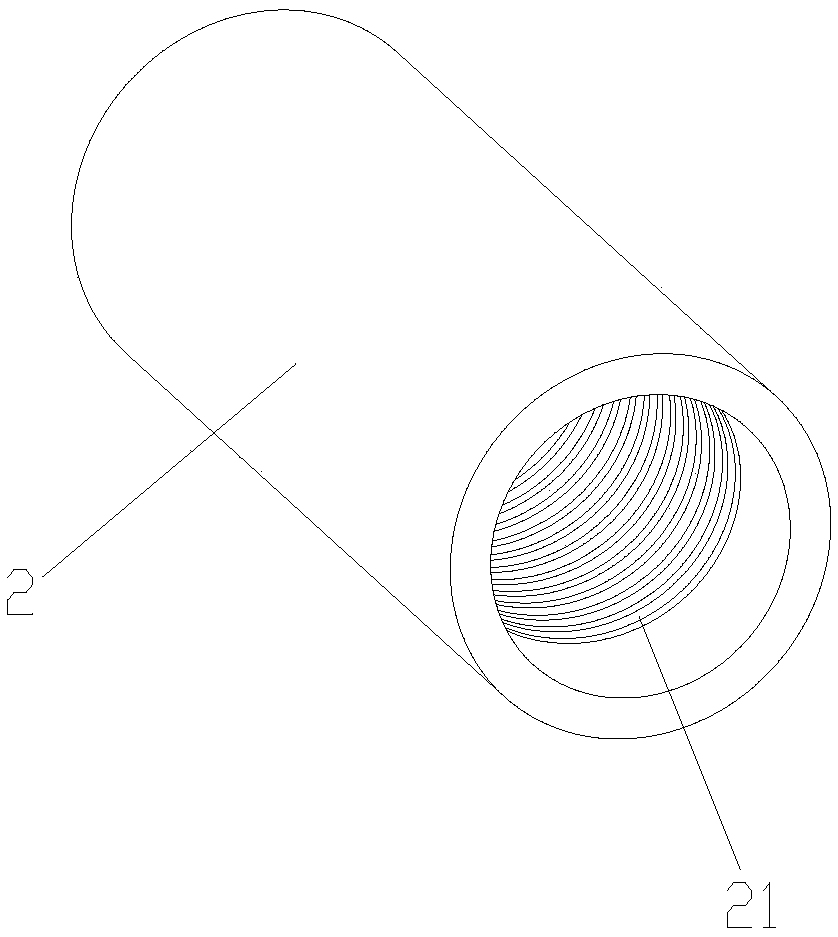

[0036] Figure 1 to Figure 6 It schematically shows the structure of a refrigeration cylinder according to an embodiment of the present invention.

[0037] Such as Figure 1 to Figure 6 As shown, the refrigeration cylinder includes an inner cylinder 1 , an outer cylinder 2 and at least two pipe bodies 3 .

[0038] Such as figure 1 As shown, in the present embodiment, the inner cylinder 1 and the outer cylinder 2 are all cylindrical, the outer cylinder 2 is sleeved on the outer wall of the inner cylinder 1, and the pipe body 3 is helical ( figure 2As shown), the pipe body 3 is located between the inner cylinder 1 and the outer cylinder 2, and the inner cylinder 1 is used to place the ice cream slurry. In other embodiments, according to actual needs, the shapes of the inner cylinder 1 and the outer cylinder 2 can also be changed, such as setting the cross ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap