Solid-liquid separation equipment using inertial mixed flow mode

A solid-liquid separation and mixed-flow technology, applied in the industrial field, can solve problems such as user trouble, inconvenient use, and complex structure, and achieve the effects of alleviating the use of raw materials, reducing the cost of use, and effectively utilizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

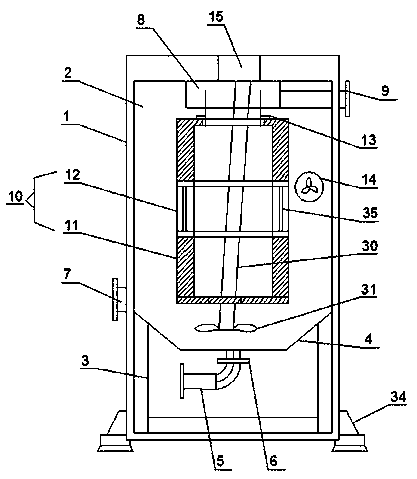

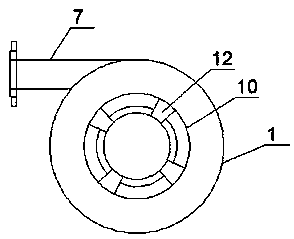

[0027] Such as Figure 1-4 As shown, the solid-liquid separation equipment using inertial mixed flow according to the embodiment of the present invention includes a water tank 1, and the water tank 1 is provided with a separation chamber 2 and a water inlet chamber 3 from top to bottom, and the separation chamber 2 and the A dividing plate 4 is arranged between the water inlet chambers 3, the section of the dividing plate 4 is a trapezoidal structure, and a return pipe 5 is arranged in the middle of the top end in the water inlet chamber 3, and the top end of the return pipe 5 penetrates through the partition. plate 4 and extends into the separation chamber 2, and the return pipe 5 is provided with a control valve 6, one side of the water tank 1 is provided with a water inlet pipe 7, and one side of the water inlet pipe 7 extends the In the separation chamber 2 and at the top side of the partition 4, the top in the separation chamber 2 is provided with a drainage groove 8, and...

Embodiment 2

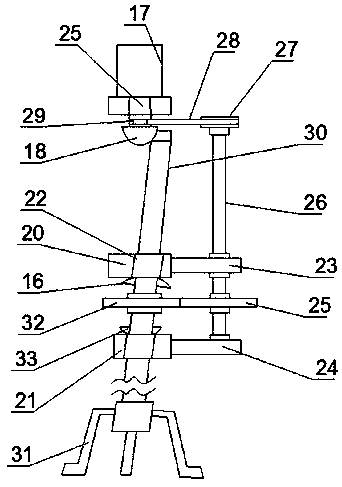

[0030] Such as Figure 3-4 As shown, the vortex mechanism 15 includes a drive motor 17 located on the top inner wall of the water tank 1, the output end of the drive motor 17 penetrates the cylinder 11 and extends to the bottom end of the separation chamber 2. Shaped rotating shaft 18, one side of the L-shaped rotating shaft 18 and a side plate 19 is arranged in the inner wall of the water tank 1, and a limit plate is symmetrically arranged on one side of the side plate 19 and located below the L-shaped rotating shaft 18 One 20 and limiting plate two 21, the bottom ends of said limiting plate one 20 and said limiting plate two 21 are all provided with holes 22, said limiting plate one 20 and said limiting plate two 21 One side is respectively provided with connecting rod one 23 and connecting rod two 24, and between said connecting rod one 23 and said connecting rod two 24, a gear plate 25 is arranged, and the bottom end of said gear plate 25 is connected with said connecting ...

Embodiment 3

[0032] Such as Figure 1-4As shown, a rolling ball 16 matching the hole 22 of the limiting plate 20 is provided above the gear tooth 1 32, the rolling ball 16 is a semicircular structure, and the bottom end of the water tank 1 There are several evenly distributed feet 34 . Further, the gear plate 25 is connected to the connecting rod 2 24 through a bearing 1, and a bearing 2 is provided at the intersection of the rotating shaft 2 26 and the connecting rod 1 23, and the water inlet tank 12 is provided with Filter screen 35, the aperture of described filter screen 35 is 0.2mm, and described water inlet pipe 7 and described water outlet pipe 9 are all provided with control valve two, and the pushing flow direction of described swirl propeller 14 is clockwise. flow.

[0033] Working principle: During normal operation, the solid-liquid mixture enters the bottom of the equipment from the water inlet pipe and forms a swirling flow. The inertial separation mechanism is fixed inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com