A reforming reactor and its application

A technology for reforming reactors and reactors, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of reducing reactor height and waste of head space, etc., to improve reasonable distribution and solve waste of head space Larger, height-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] further reference figure 1 Describe in detail.

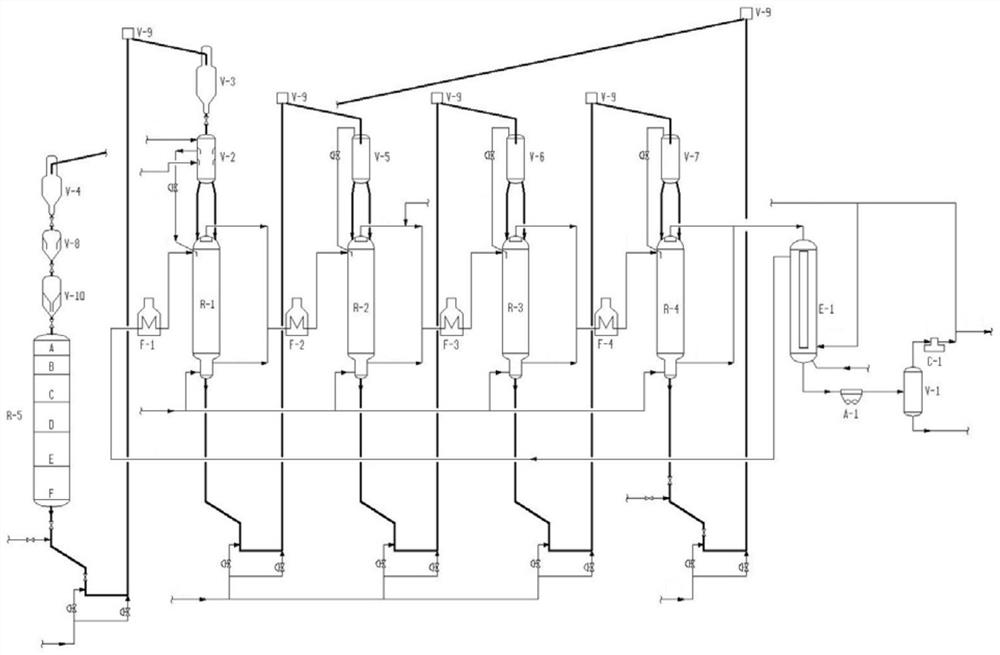

[0059] A catalytic reforming unit for refined gasoline (distillation range 80°C-175°C) includes a reaction section and a regeneration section, the reaction section consists of a first reforming reactor R-1, a second reforming reactor R-1, and a second reforming reactor operated in series. The reactor R-2, the third reforming reactor R-3, and the final reforming reactor R-4 are composed of four reactors, and the regeneration part includes the step I of catalyst burning (two-stage burning), using Step II for oxidation with chlorine to redisperse precious metal crystallites, and step III for reduction with hydrogen before being able to reduce the catalyst before it is reintroduced into the reactor.

[0060] The reaction part is in figure 1 In the middle, the first reforming reactor R-1, the second reforming reactor R-2, the third reforming reactor R-3, and the final reforming reactor R-4 are presented in a "side-by-side" c...

Embodiment 2

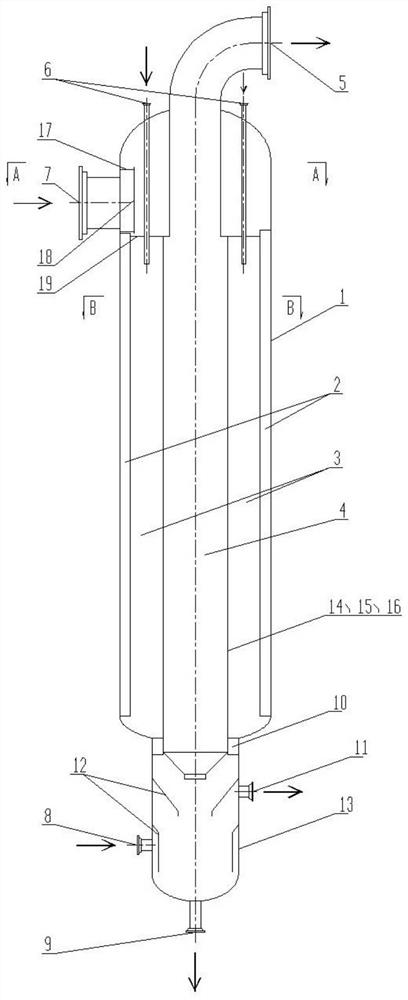

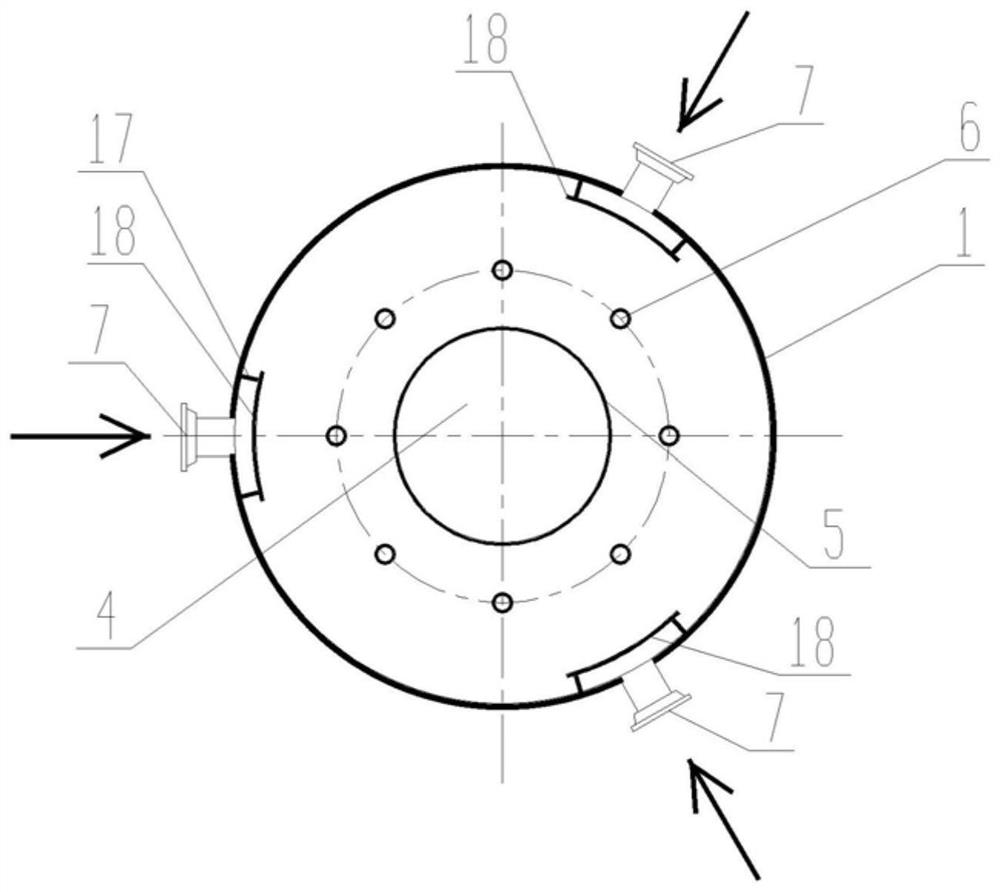

[0078] A reforming reactor, its structure is as Figure 2-4 As shown, the reforming reactor used adopts a radial bed structure, including a cylinder 1 , an upper head, a lower head, and a catalyst collection hopper 13 and other components. The upper head and the lower head are respectively arranged at both ends of the cylinder body 1, and are fixedly connected with the cylinder body to form a sealed structure, and the catalyst collecting bucket 13 is located under the lower head. The upper head used is spherical or ellipsoidal, and the corresponding shape or structure can be selected arbitrarily according to the actual situation. The top is provided with a reaction product outlet 5 and a catalyst feed pipe. The end of the catalyst feed pipe located outside the cylinder body 1 is the catalyst inlet 6, and the reaction product outlet 5 communicates with the central cylinder 4. The catalyst feed pipes are evenly distributed along the circumference, and the number set in this emb...

Embodiment 3

[0090] A reforming reactor, its structure is as figure 2 As shown, the reforming reactor used adopts a radial bed structure, including a cylinder 1 , an upper head, a lower head, and a catalyst collection hopper 13 and other components. The upper head and the lower head are respectively arranged at both ends of the cylinder body 1, and are fixedly connected with the cylinder body to form a sealed structure, and the catalyst collecting bucket 13 is located under the lower head. The upper head used is spherical or ellipsoidal, and the corresponding shape or structure can be selected arbitrarily according to the actual situation. The top is provided with a reaction product outlet 5 and a catalyst feed pipe. The end of the catalyst feed pipe located outside the cylinder body 1 is the catalyst inlet 6, and the reaction product outlet 5 communicates with the central cylinder 4. The catalyst feed pipes are evenly distributed along the circumference, and the number provided in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com