Automatic discharging machine

A technology of automatic unloading and unloading machine, which is applied in the direction of conveyor, loading/unloading, conveyor objects, etc., to achieve the effect of not easy to deviate, improve the degree of automation, and stabilize the unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

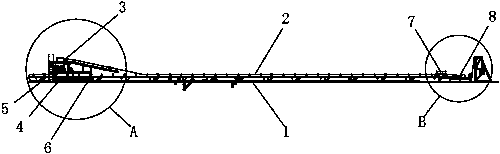

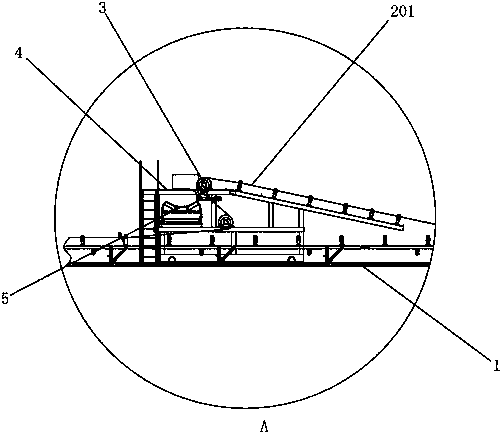

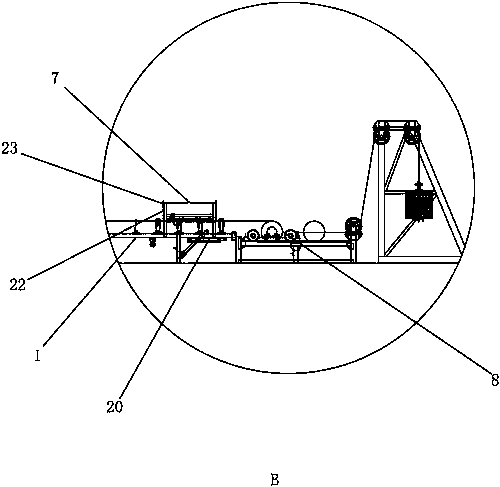

[0024] Embodiment 1: a kind of automatic unloading machine, as Figure 1 to Figure 4 As shown, it includes a frame 1 and a support 4 arranged on the top of the frame 1. The frame 1 selects a gantry frame extending horizontally along the left and right directions, and the support 4 extends horizontally along the front and rear directions. Transport to the first transport mechanism 2 on the support 4. In this embodiment, the first transport mechanism 2 includes a first conveyor belt 201 arranged horizontally along the length direction of the frame 1 and a first drive for driving the first conveyor belt 201 to transport materials. Components, the first drive part is the first drive motor, the first drive motor works, drives the first conveyor belt 201 to transport the material from the right end of the frame 1 to the left end, and the first conveyor belt 201 discharges the material in the middle of the frame 1 At one end, a discharge roller 3 is arranged on the upper end of the s...

Embodiment 2

[0031] Embodiment 2: a kind of automatic unloading machine, differs from embodiment 1 in that, as Figure 4 As shown, the support 4 includes a sliding frame 21 extending along the feeding direction of the second conveyor belt 12, the sliding frame 21 slides on the support 4 along the feeding direction of the second conveyor belt 12, and the second conveying mechanism is arranged on the sliding On the shifting frame 21, the second conveying mechanism can be moved to the left or right by the sliding frame 21, thereby increasing the conveying stroke of the material on the second conveyor belt 12, so that the position where the material is stacked is far enough away from the frame 1 to reach The stacking effect is better.

Embodiment 3

[0032] Embodiment 3: a kind of automatic unloading machine, the difference with embodiment 6 is, as Figure 6 As shown, on the basis of Embodiment 1, a blower blowing along the extension direction of the second conveyer belt 12 is arranged in the bin body 9, and the blower is arranged at one end of the bin body 9, and is arranged on the bin body 9 at the opposite end. Ventilation hole is arranged, and filter screen 19 is arranged on the ventilation hole, and the wind power of blower is less, can blow the dust in the material to ventilation hole, fly out from the mesh of filter screen 19 then, and material normally falls downwards, filter Net 19 can prevent a little material from flying out from the air vent, and plays the effect of removing dust.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com