Large-span pre-stressed main girder portal crane

A gantry crane, prestressing technology, applied in the direction of load block, load hanging components, transportation and packaging, etc., can solve the problems of small vertical rigidity of the main girder, large climbing of the lifting trolley, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

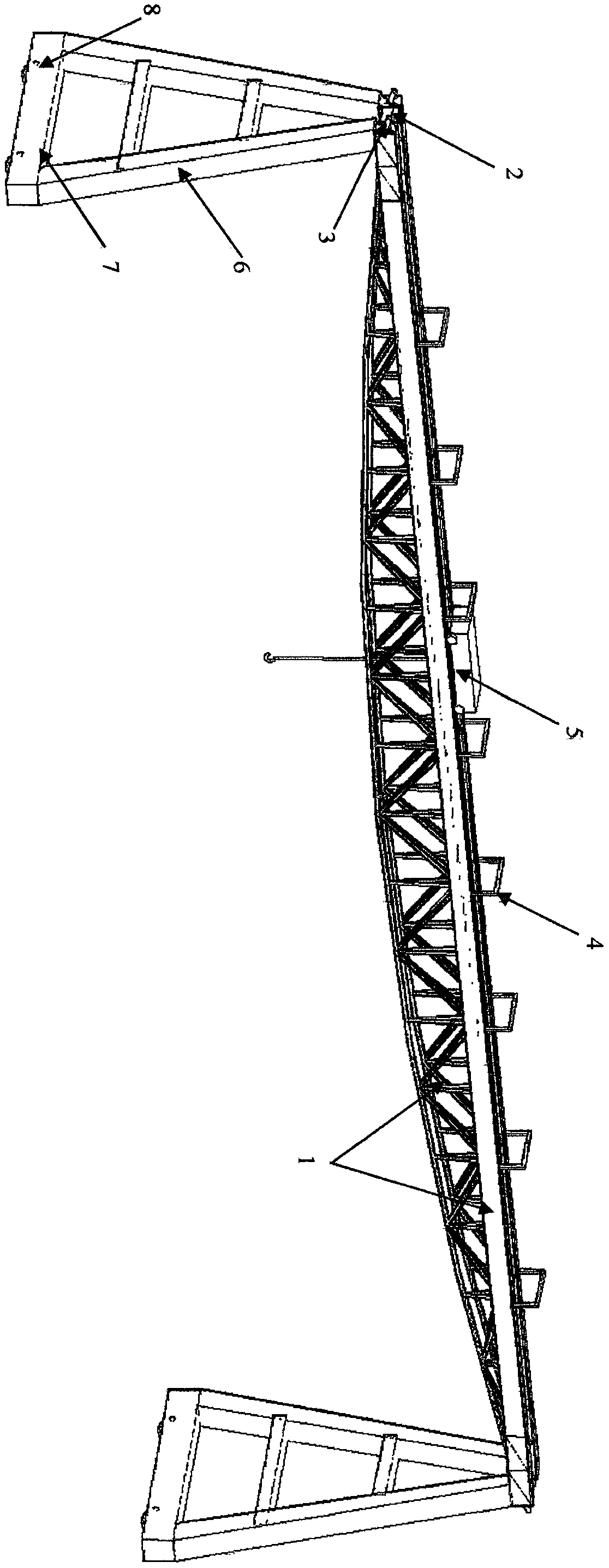

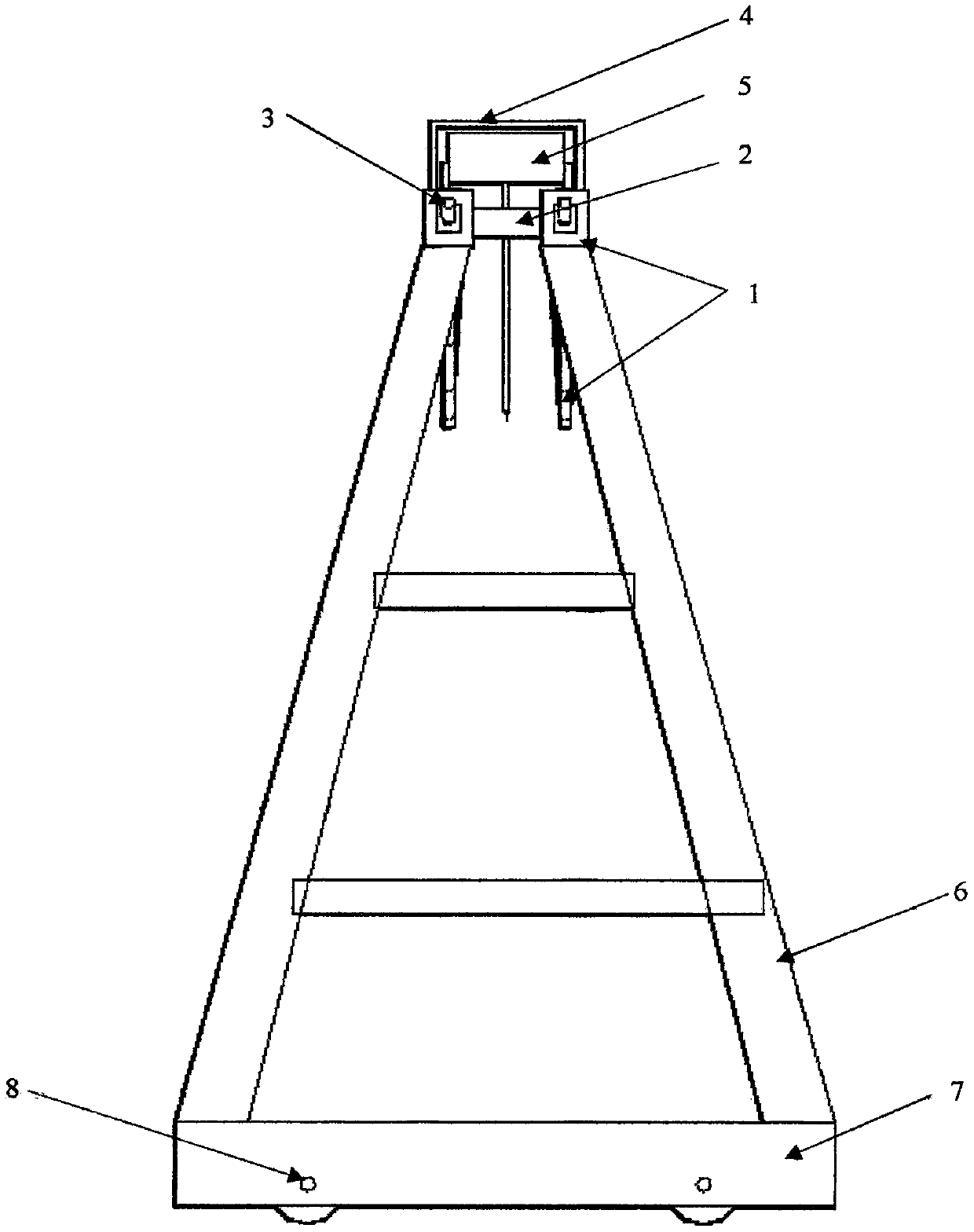

[0023] like figure 1 , figure 2 As shown, a kind of large-span prestressed main girder gantry crane according to the present invention is a steel box girder with a span of 100m, a lifting capacity of 32t, and a height of 20m and a prestressed steel structure girder gantry crane combined with an arc-shaped steel pipe arch frame. Including prestressed main beam 1, end beam 2, anti-rust and anti-flying anchor sleeve 3, cross-link frame 4, lifting trolley 5, outrigger 6, lower beam 7 and cart operating mechanism 8, the prestressed main beam 1 is installed on the outrigger 6, the ends of the two main girders are connected by the end girder 2, and a cross-bending frame 4 is installed above the main girder, and the anti-rust and anti-flying anchor sleeve 3 is installed on the prestressed main girder 1 end face, the lower crossbeam 7 is installed on the bottom of the outrigger 6, the cart operating mechanism 8 is installed on the lower crossbeam 7 to make the crane move longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com