High-temperature demulsification method for waste emulsion

A waste emulsion and emulsion technology, applied in chemical instruments and methods, separation methods, liquid separation, etc., can solve problems such as increasing difficulty in processing, and achieve simple and efficient oil-water separation, high oil yield, and cost-saving effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Unless otherwise defined, technical terms used in the following embodiments have the same meanings as commonly understood by those skilled in the art to which the present invention belongs. The test reagents used in the following examples are conventional biochemical reagents unless otherwise specified; the experimental methods are conventional methods unless otherwise specified.

[0033] The present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

[0034] A high-temperature demulsification method for waste emulsion, comprising the following steps:

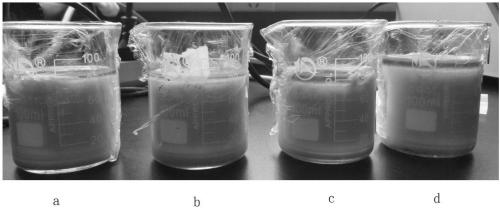

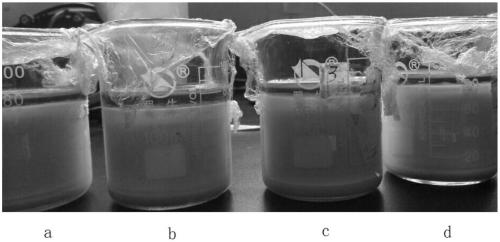

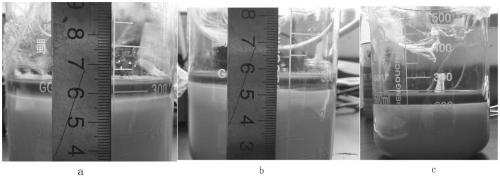

[0035] (1) Take a certain amount of waste emulsion and heat it at a certain temperature for heat preservation or boiling for a certain period of time. After cooling to room temperature, the stratification boundary is obvious, and the oil slick is removed;

[0036] (2) get the middle and lower layer emulsion in step (1) and heat and boil again for a certain period...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com