Organic sludge dehydration and drying treatment device

A technology of organic sludge and treatment equipment, which is applied in the directions of sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc. It can solve problems such as poor effect, cumbersome process, and lengthy equipment production line. Achieve the effect of simple processing procedure, improve processing efficiency, and save plane space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

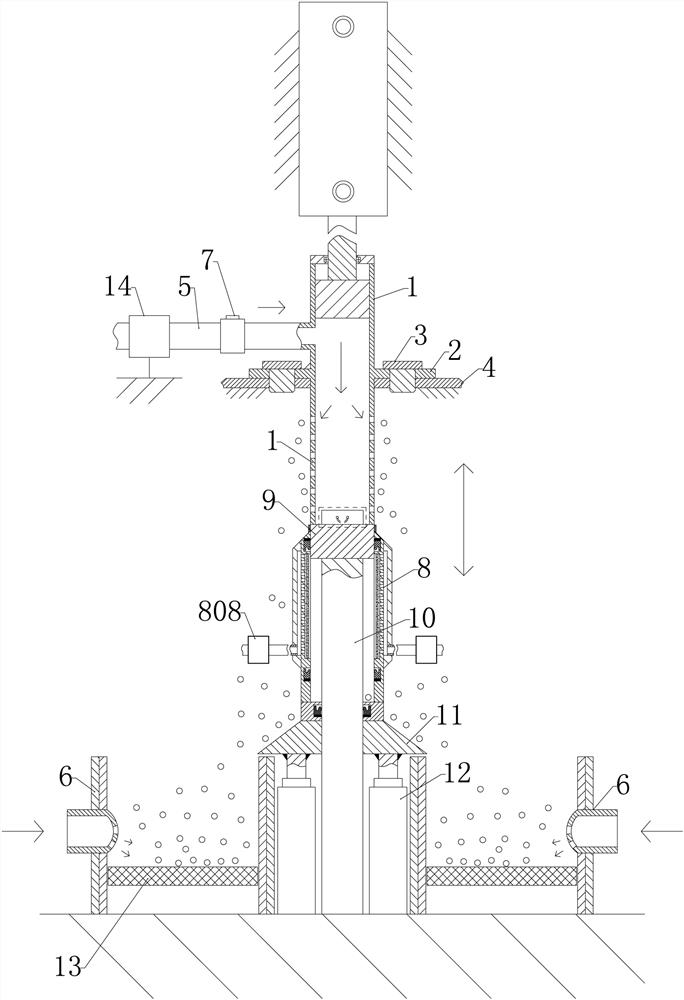

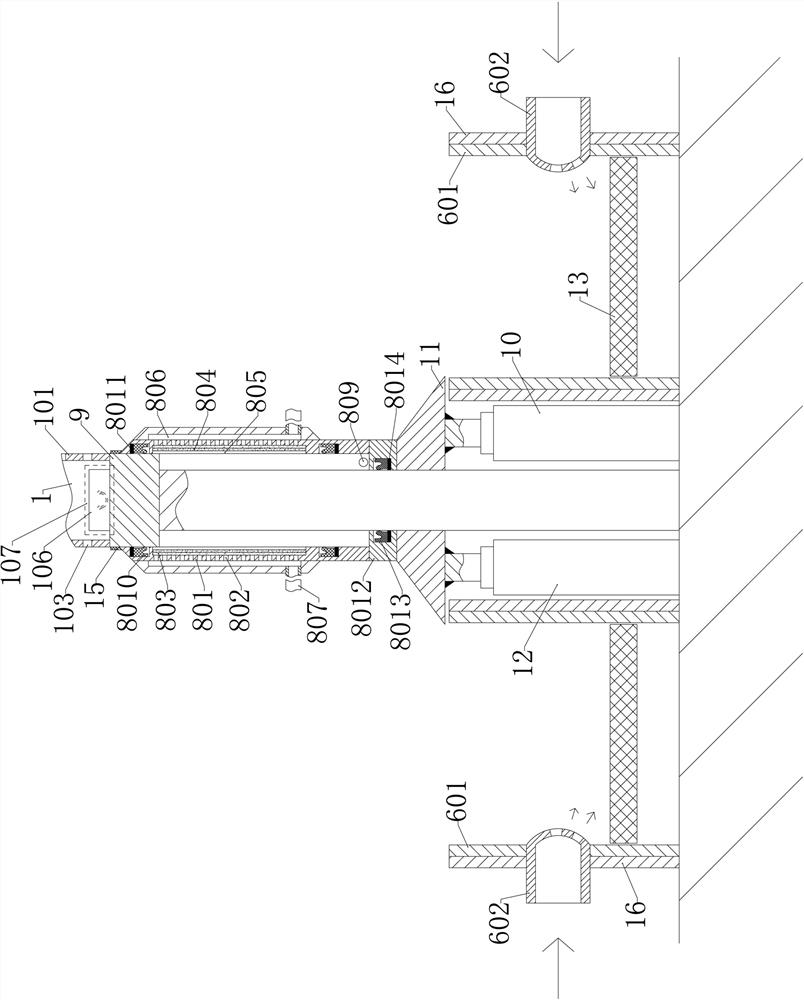

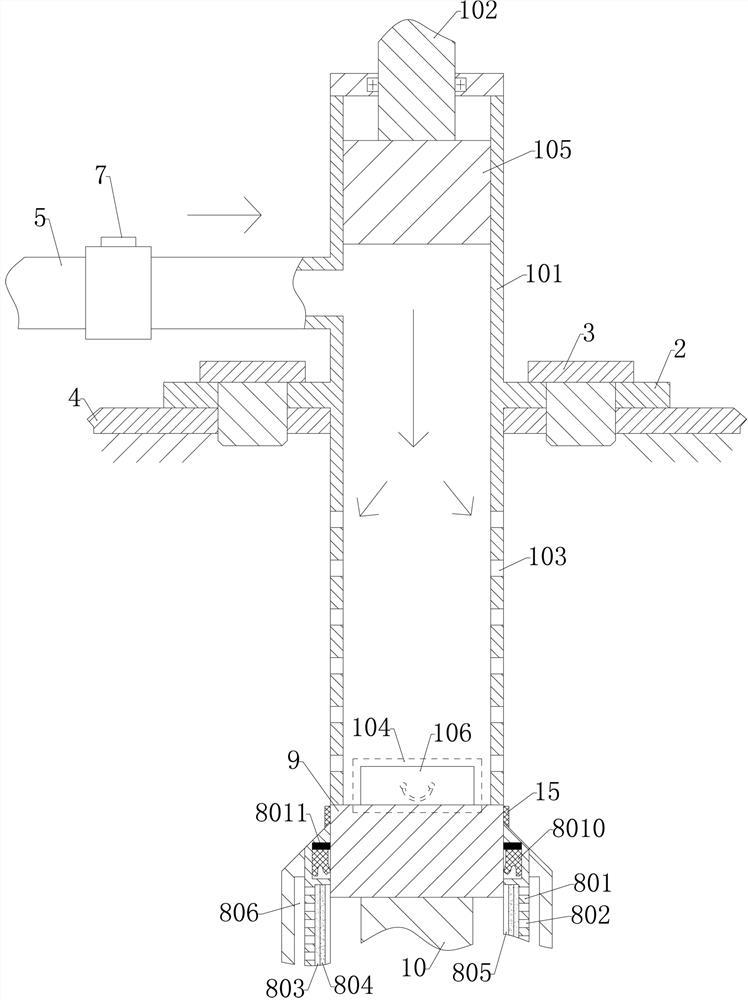

[0021] like Figure 1-5 As shown in , the organic sludge dehydration and drying treatment device includes a sludge extruding device 1, the upper outer side wall of the sludge extruding device 1 is connected to the On the frame body 4 fixedly connected to the ground, the sludge extruding device 1 communicates with its interior through the feed pipe 5 arranged on the upper part of the fixed plate 2, and a sludge pump 14 and a switch are arranged on the feed pipe 5 Valve 7, the bottom of the sludge extruding device 1 is fixedly connected with a support seat 9 with the same outer diameter as the sludge extruding device 1, and the support seat 9 is fixed on the ground through a vertical column 10 A sludge dewatering and water guiding device 8 is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com