Method for improving warm deformation plasticity of high silicon steel sheet by adding heavy rare earth yttrium element

A steel slab and heavy rare earth technology, applied in the field of metal material preparation, achieves important academic value and economic value, and promotes sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

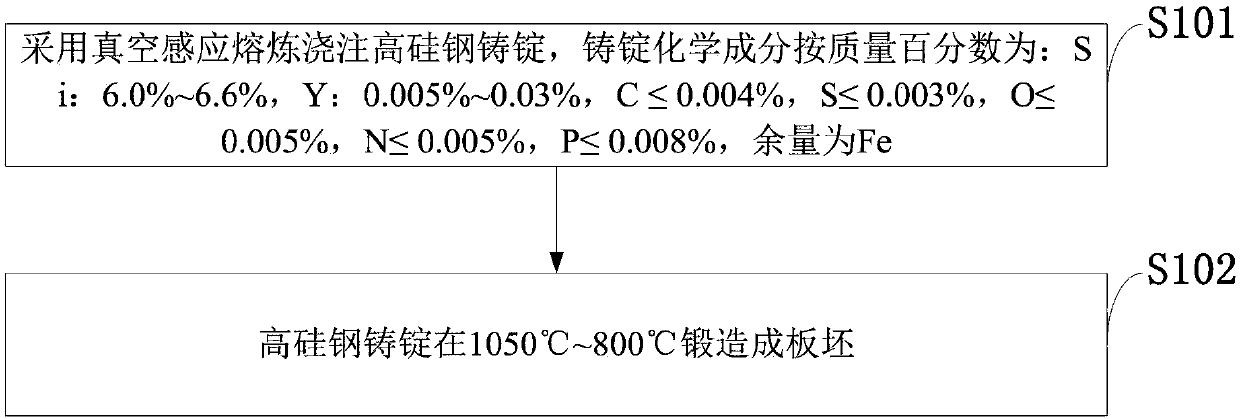

Method used

Image

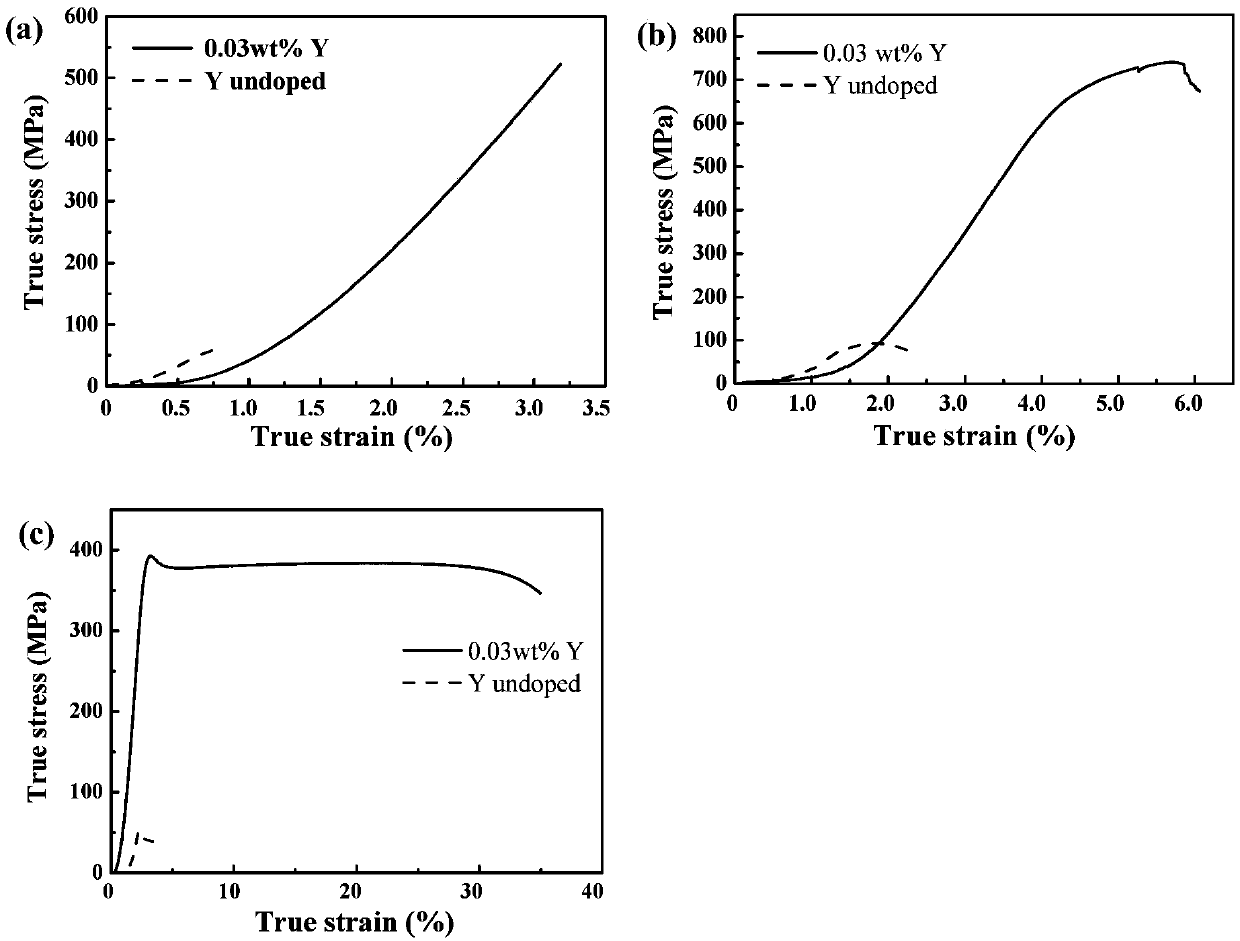

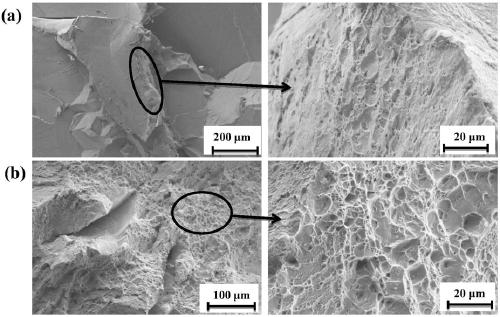

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0026] At present, scholars at home and abroad only use Ce and La as rare earth elements added to electrical steel, both of which belong to light rare earth elements, and there is no report on the application of heavy rare earth yttrium (Y) element in electrical steel. The invention opens up a new direction for the application of rare earth Y, promotes the sustainable development of the rare earth industry, and at the same time promotes the industrialization of high-silicon steel, and transforms the advantages of rare earth resources into the variety and economic advantages of steel products, and has important academic and e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com