A post-finishing process without lint

A post-finishing and process technology, applied in the field of post-finishing process without velvet, can solve the problems of unfavorable market promotion, folding and printing, high price, etc., and achieve the effect of speeding up the conveying speed of the fabric, avoiding deformation, and making the suede soft.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A post-finishing process without tufting, comprising the following steps:

[0032] S1, unwinding of the embryonic cloth, unwinding the woven white embryonic cloth without tension and placing it in the barrel car; during the unwinding process, ensure that the embryonic cloth is not under tension, so as to avoid the deformation of the embryonic cloth and the occurrence of the edge of the embryonic cloth In the case of creases caused by hemming;

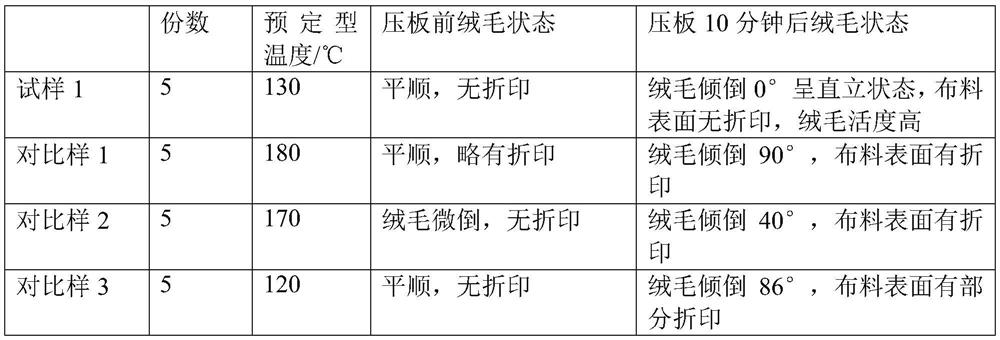

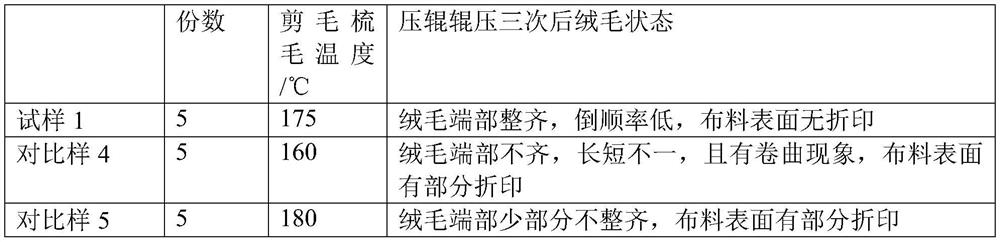

[0033] S2, pre-forming, using a hot-air stenter and setting machine, and its rated air volume is 4000rmp, the white cloth is fed into the setting machine, the temperature is adjusted to 120-140 degrees, the fabric conveying speed is 30m / min, and the fabric is above the setting machine. The air volume of the bellows is turned on to 50%, and the air volume of the lower bellows is turned on to 70%; the lower air volume is greater than the upper air volume, so that the loop of the fabric is always in a vertical state during the conve...

Embodiment 2

[0041] A post-finishing process without tufting, comprising the following steps:

[0042] S1, unwinding of the embryonic cloth, unwinding the woven white embryonic cloth without tension and placing it in the barrel car; during the unwinding process, ensure that the embryonic cloth is not under tension, so as to avoid the deformation of the embryonic cloth and the occurrence of the edge of the embryonic cloth In the case of creases caused by hemming;

[0043] S2, pre-forming, using a hot-air stenter and setting machine, and its rated air volume is 4000rmp, the white cloth is fed into the setting machine, the temperature is adjusted to 110-140 degrees, the fabric conveying speed is 30m / min, and the fabric is above the setting machine. The air volume of the bellows is turned on to 50%, and the air volume of the lower bellows is turned on to 70%; the lower air volume is greater than the upper air volume, so that the loop of the fabric is always in a vertical state during the conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com