Oil depot assembly type fire dike construction method

A construction method and technology of fire embankment, applied in fire prevention, fire rescue, dental restoration, etc., can solve problems such as heavy workload, long construction period, and difficulty in quality control, so as to reduce pollution, reduce impact, and eliminate The effect of construction risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing and embodiment:

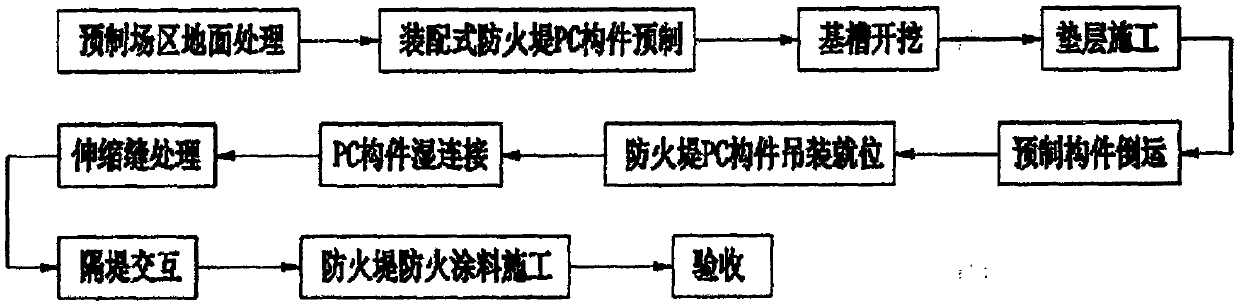

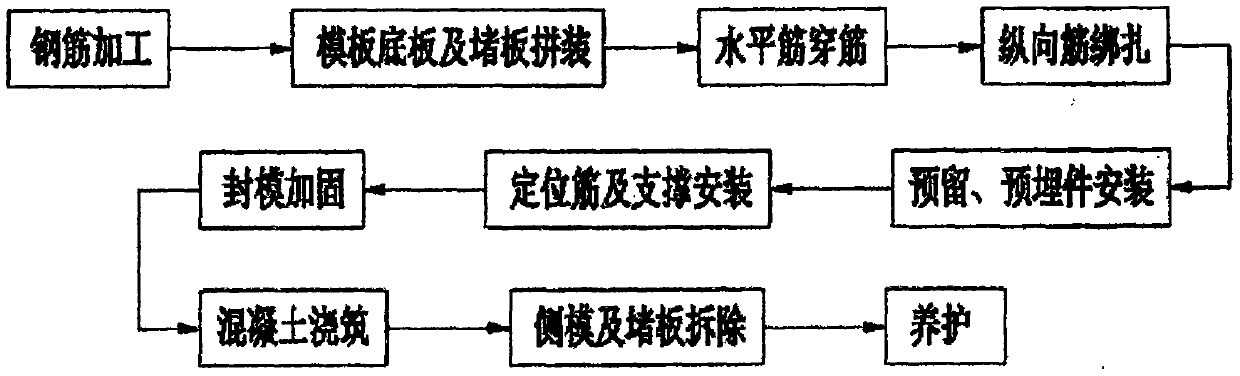

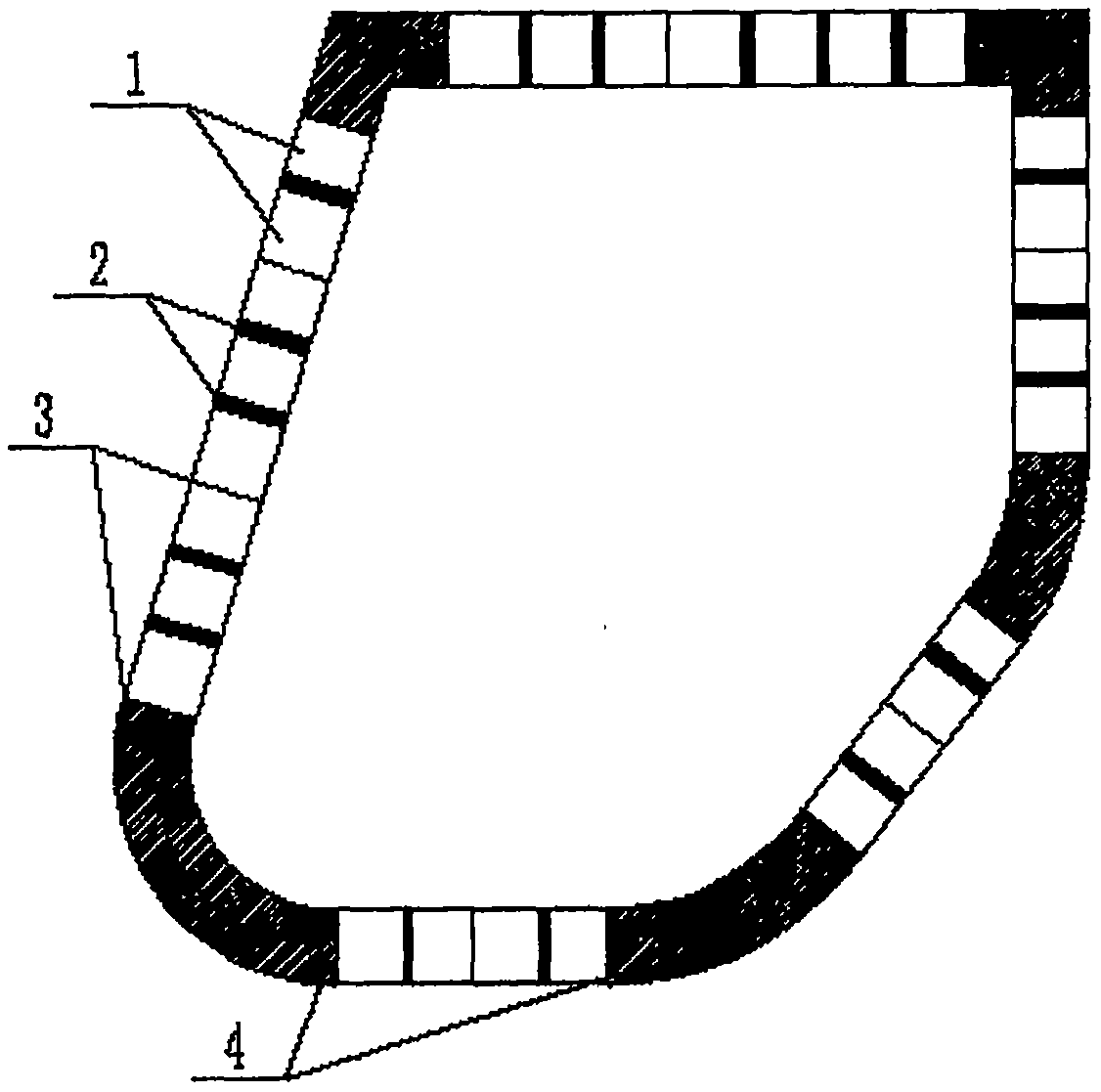

[0043] The invention relates to a construction method of an oil depot assembly type fire embankment and a method for prefabricating a fire embankment beam. The assembled fire embankment beam is used to carry out the construction of the fire embankment, such as image 3 As shown, the fire dike is decomposed as a whole into several fire dike PC components 1, and then the prefabricated fire dike PC components 1 are connected with post-casting tape 2 or expansion joint 3 according to the engineering requirements, and then the transition section is cast on site The way to connect with the PC components of the fire dike. The specific construction process is different from the traditional construction process, mainly including the following processes, such as figure 1 As shown, step 1. Ground treatment of prefabricated site; Step 2. Prefabricat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com