Hyperboloid metal roof and construction method thereof

A technology for metal roofs and hyperboloids, which is applied to roofs, roofs, and roof coverings that use flat/curved panels, and can solve the difficulties in installation, measurement and positioning of arched structures, complex technology and complex spatial structures of hyperbolic arched roofs and other problems, to achieve the effect of facilitating connection tolerance and welding stress, smooth dimension lines, and improving the structural strength against deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

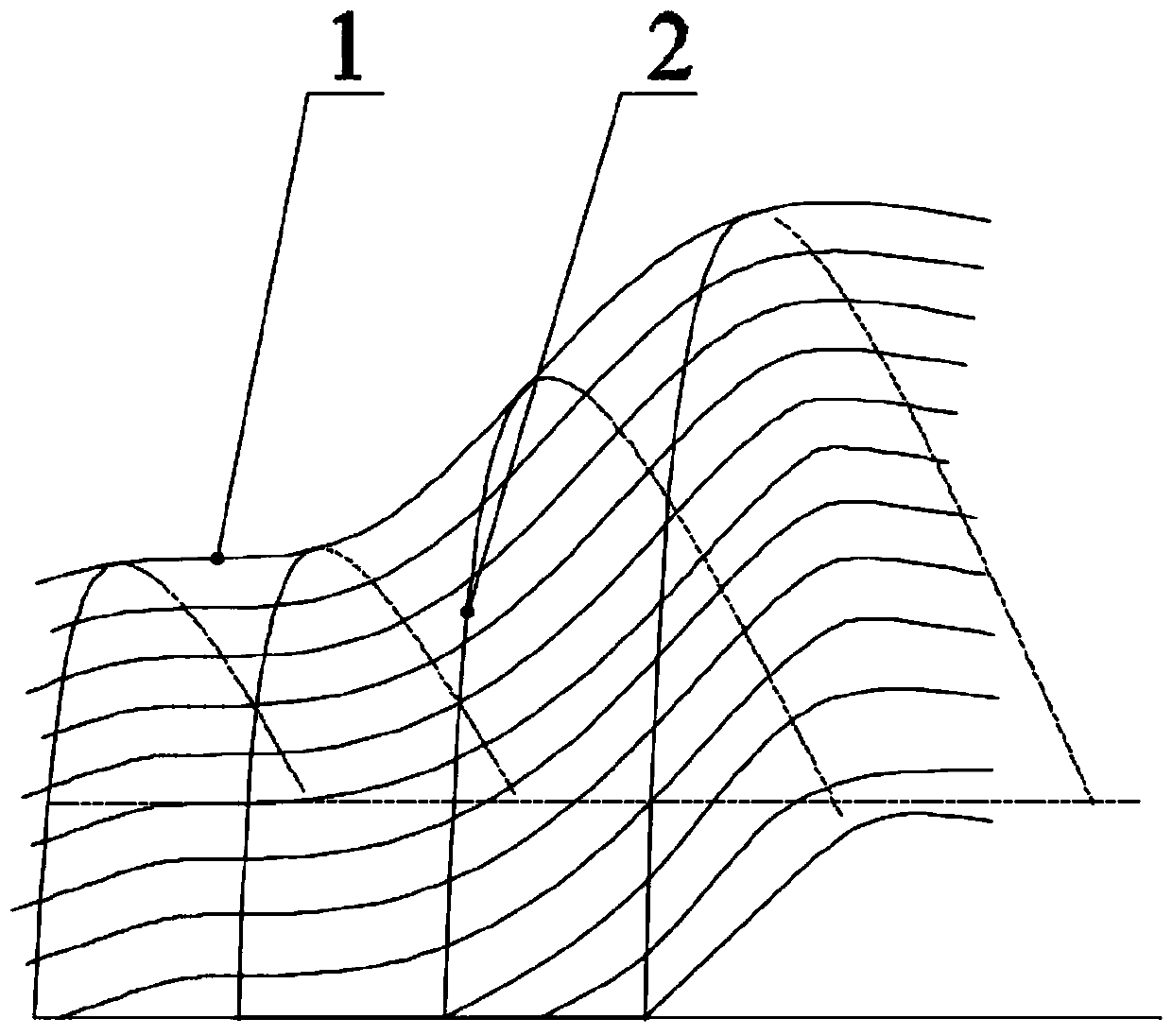

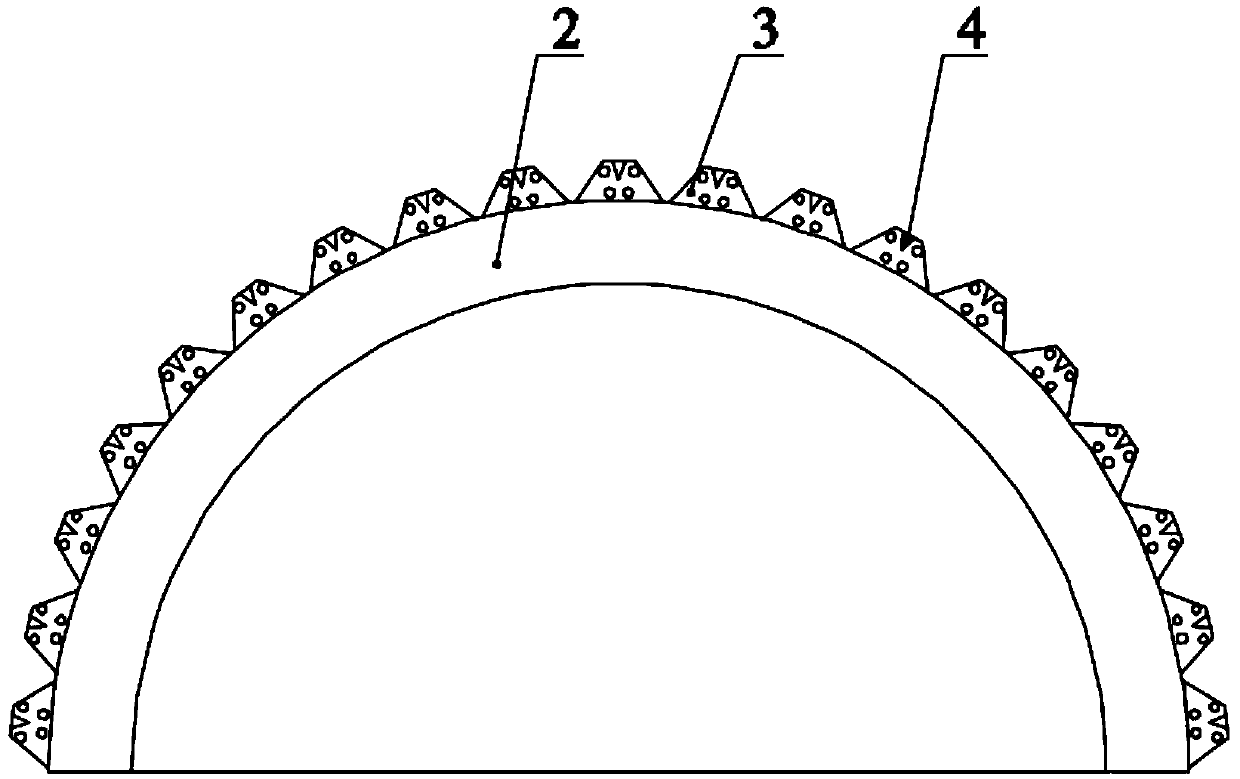

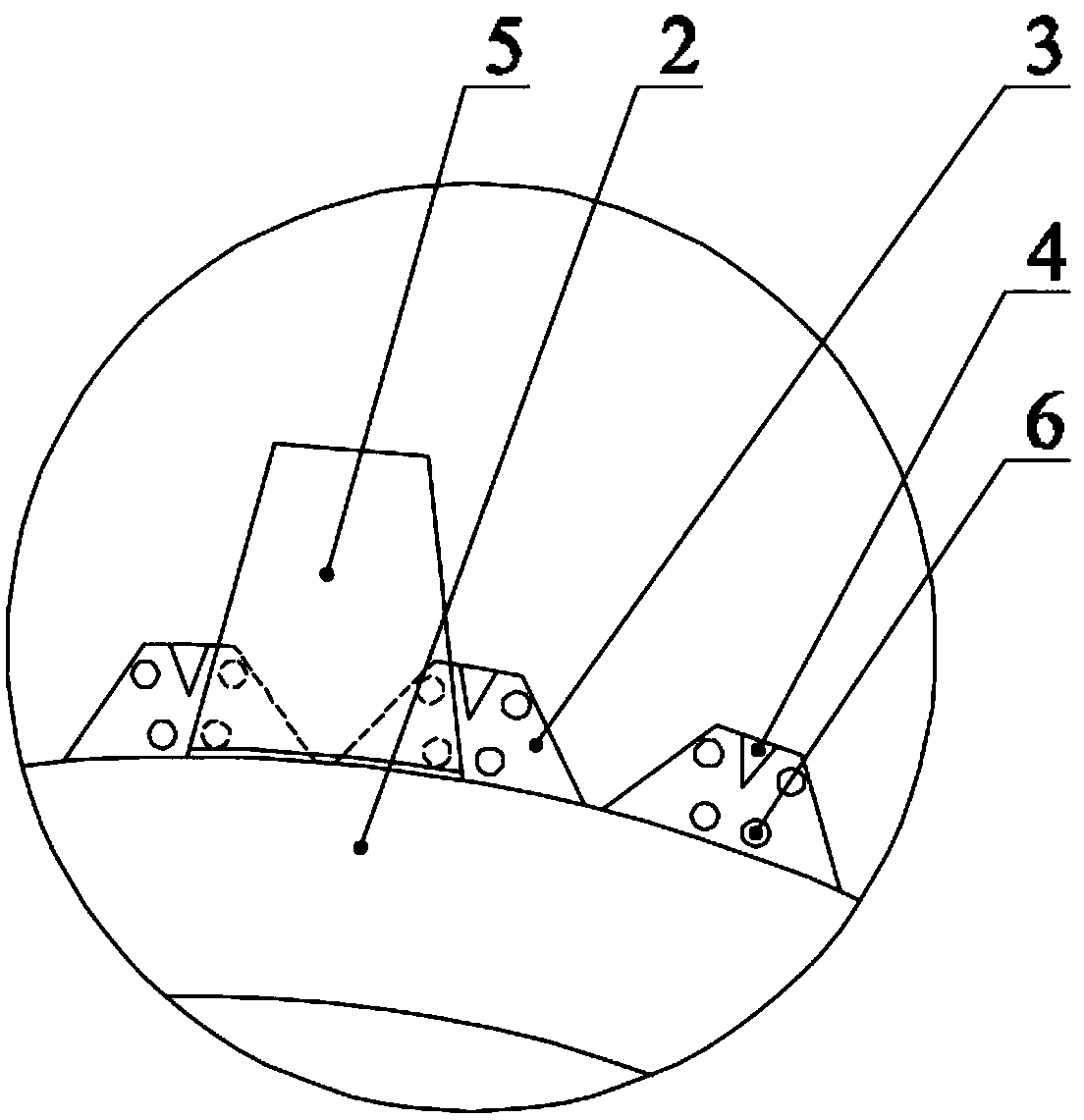

[0028] A hyperboloid metal roof, comprising a plurality of arch beams 2 arranged in sequence and a profiled plate connection unit fixedly connecting two adjacent arch beams; the profiled plate connection unit includes several strip-shaped profiled plates 1, and also includes A fixed bracket 5 for end-to-end connection and connecting several profiled plates along the direction of the arch beam arrangement, wherein the profiled plate is formed with multiple bends 10, and both sides of the profiled plate are fixed with plugs on the profiled plate. The end sealing plate at the bend of the plate; both sides of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com