Assembling jig frame of curved surface truss and construction method thereof

A tire frame and truss technology, which is applied in the field of assembled tire frame and its construction, can solve problems such as deformation, inability to ensure accurate camber, truss size, overall assembly quality, and weak lateral rigidity, so as to ensure camber, Reduce the secondary transportation work and achieve the effect of accurate arching height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

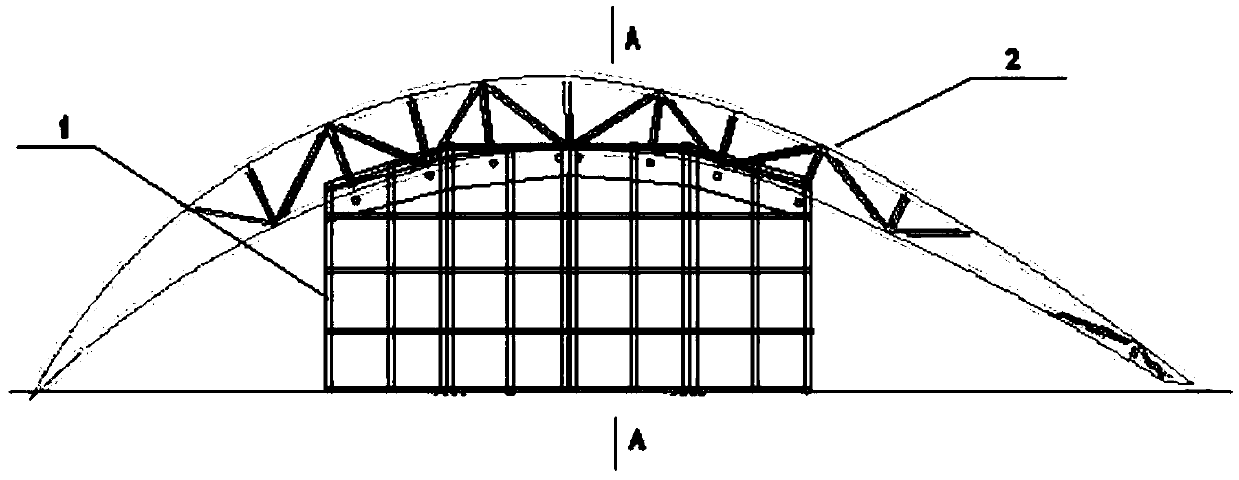

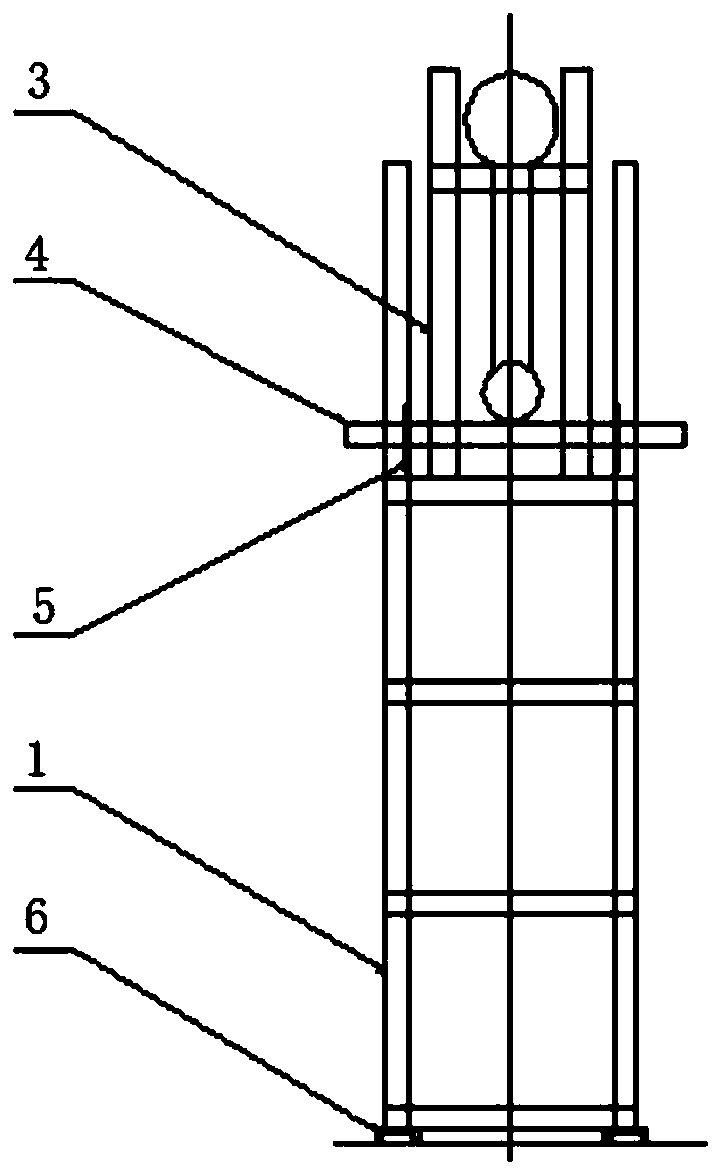

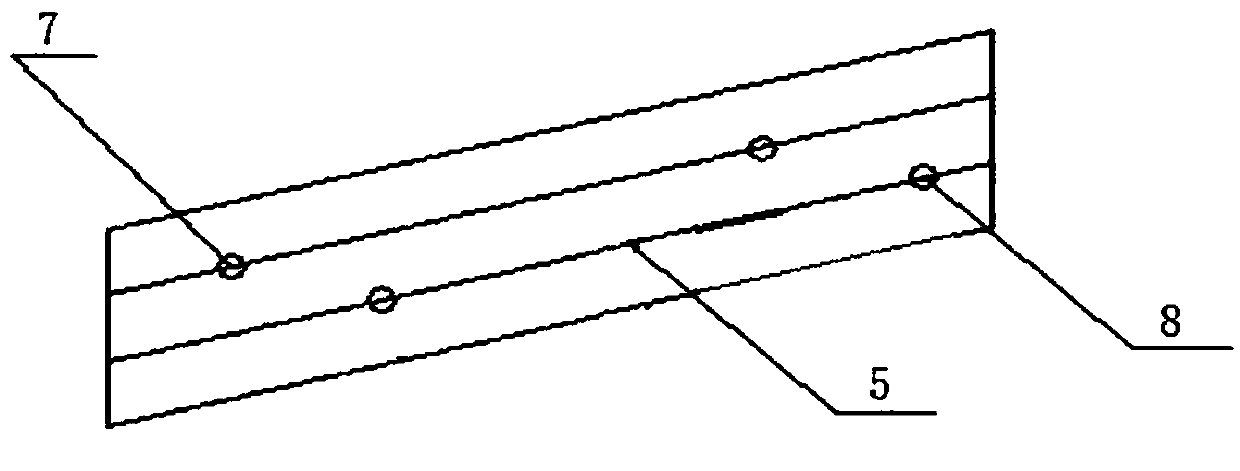

[0025] An assembled tire frame of a curved truss, the assembled tire frame 1 includes a base 6, and several tire frame sections 11 that are fixed and spliced along the extending direction of the curved truss 2 above the base; the curvature and the curved surface of the assembled tire frame top The design radian of the truss is suitable, and the two sides of the top of the assembled tire frame are symmetrical and fixed with several spliced and fixed fixing plates 5, and every two symmetrical fixing plates penetrate and are fixed with support rods 4; The top of the assembled tire frame is spliced and fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com