Double-channel reinforced composite pipe

A composite pipe and reinforced technology, applied in the field of pipelines, can solve the problems of low structural strength and poor stability, and achieve the effects of low cost, enhanced strength, and prevention of fracture or freeze cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

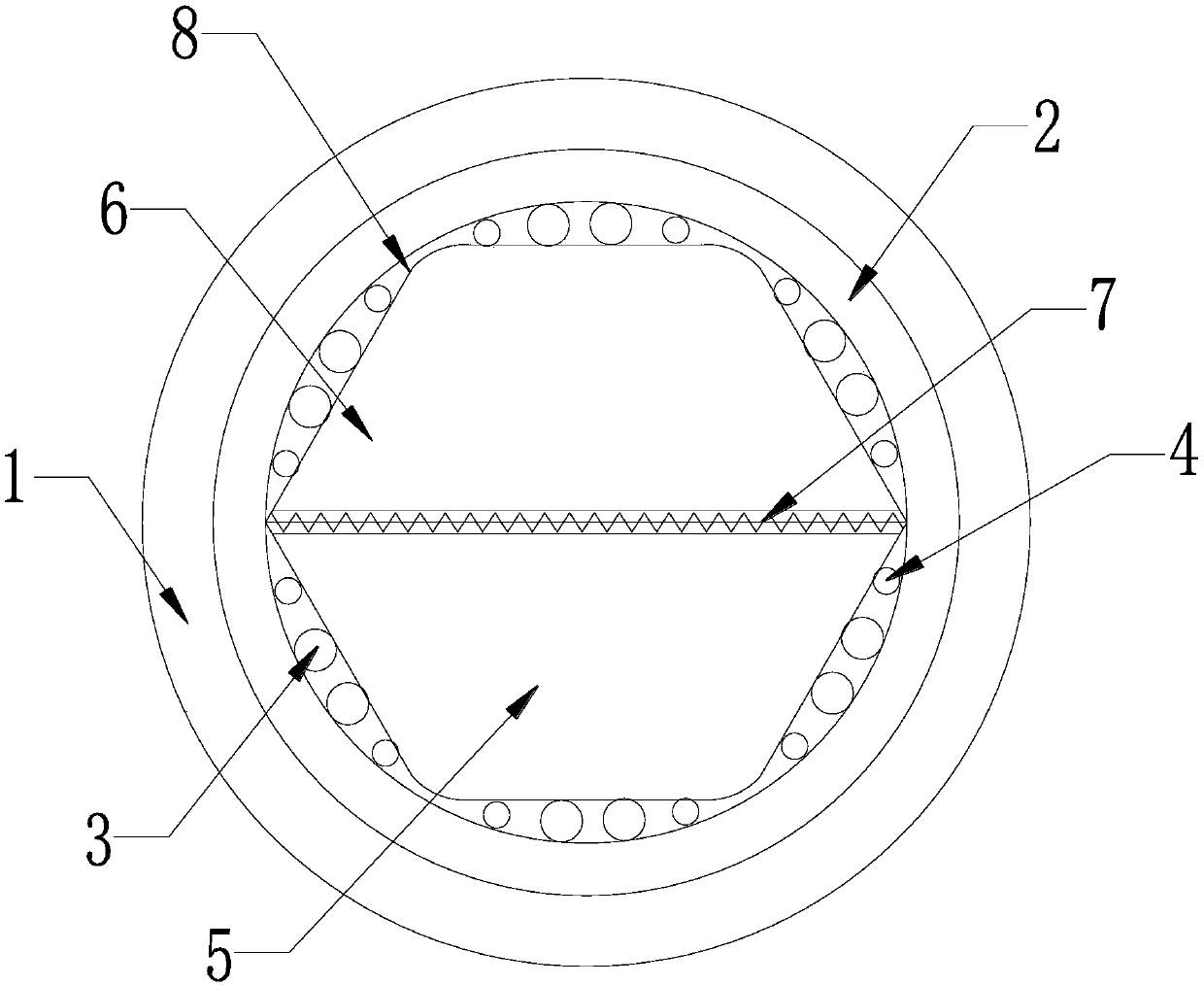

[0020] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0021] Such as figure 1 with figure 2 As shown, a dual-channel reinforced composite pipe, the composite pipe from the outside to the inside polyethylene fiber outer layer 1, steel mesh winding layer 2 and plastic resin layer 8, the cross-section of the plastic resin layer 8 is a regular hexagon, The outer wall of each side of the regular hexagon is provided with reinforcing ribs 3 and copper conductors 4. The reinforcing ribs 3 are tightly wound through the steel mesh winding layer 2, and are placed between the steel mesh winding layer 2, the reinforcing ribs 3 and the plastic resin layer 8. Silicone rubber is filled in the gap, and the channel formed by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com