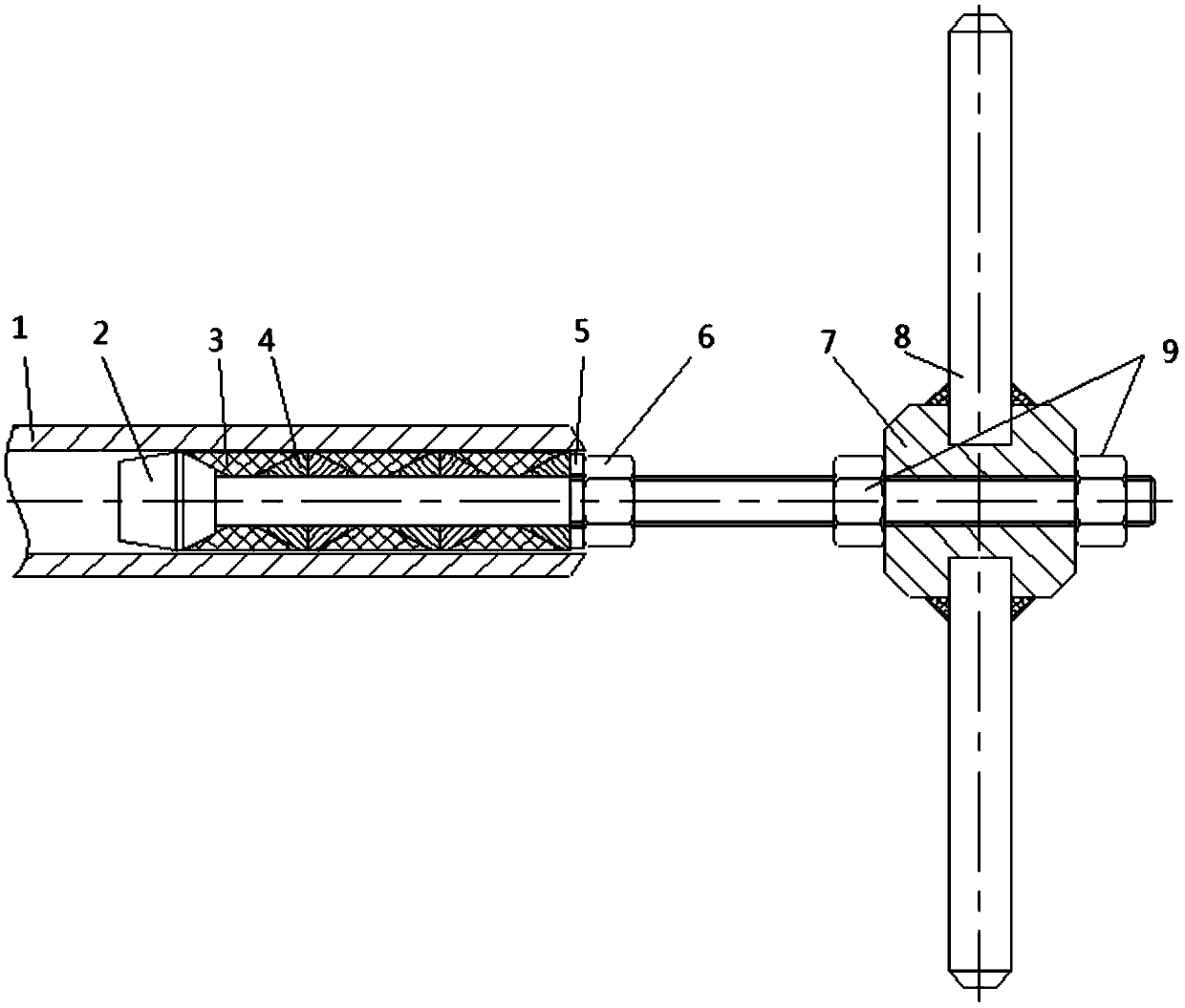

Sealing device for pipe joint

A sealing device and pipe joint technology, applied in the direction of pipe/pipe joint/pipe fitting, measuring device, fluid tightness test, etc., can solve the problems of low reuse rate, poor economy, complicated operation, etc. Inexpensive, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

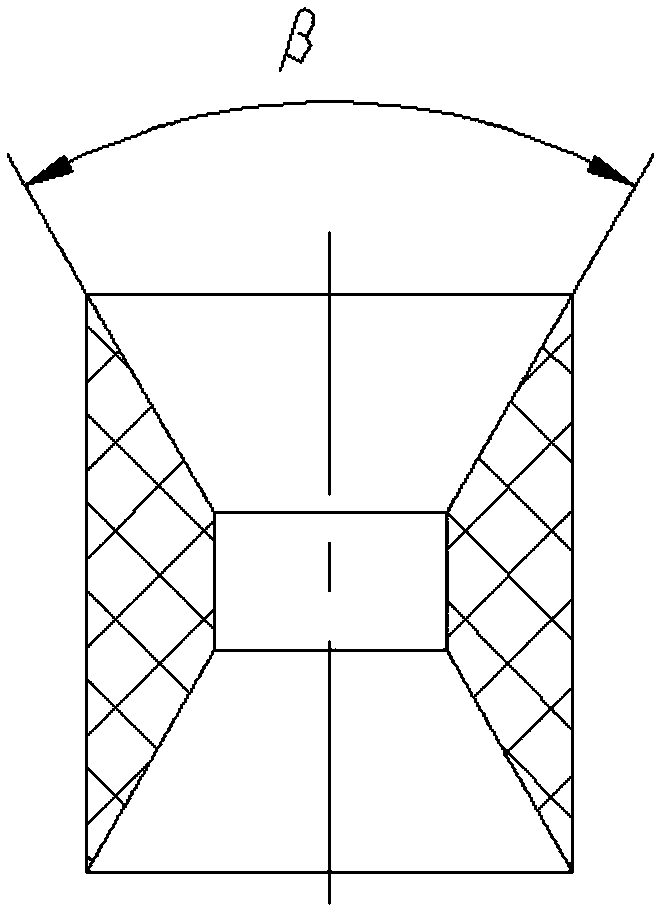

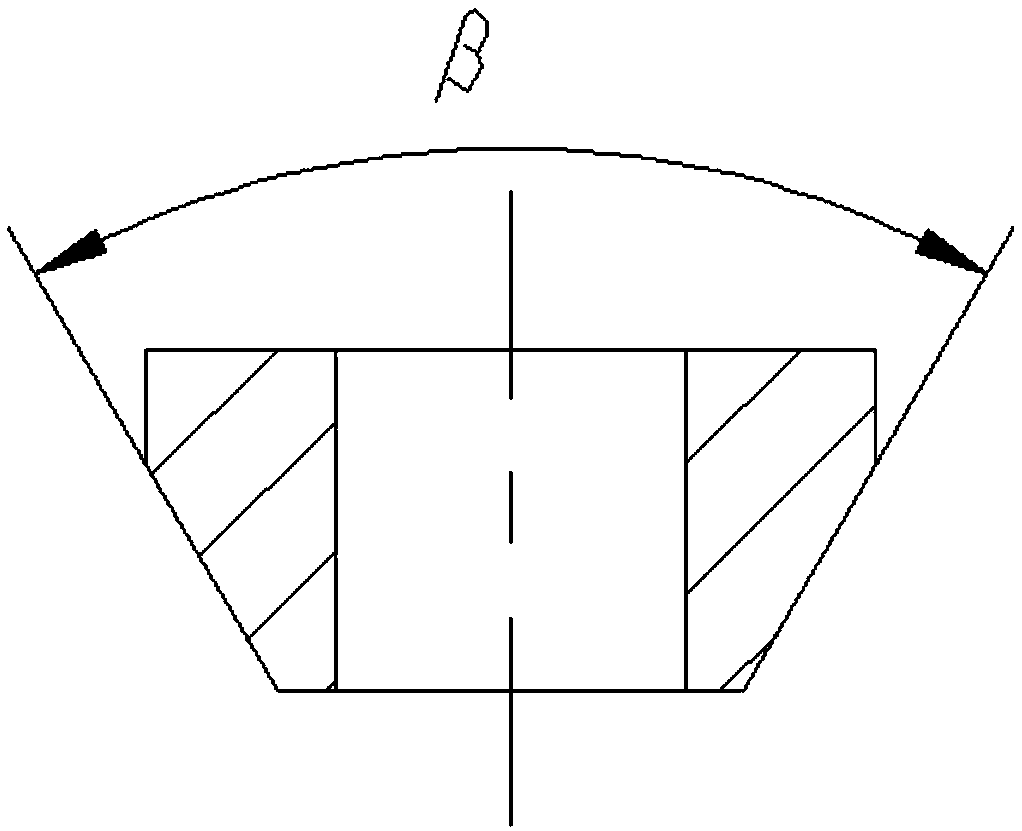

Method used

Image

Examples

Embodiment

[0083] Apply the pipe joint high-pressure sealing device of the present invention to the pressure test of the heat transfer tube of the nuclear power steam generator equipment, the specification of the heat transfer tube And the sealing (or air tightness) of the sealing device is tested,

[0084] The sealing device of the present invention is used to detect the sealing performance of the heat transfer tube of the nuclear power steam generator equipment, and it is found that there is no visible deformation and abnormal sound at the sealing part, and no air leakage is detected by applying soap liquid at the sealing boundary, and the pressure is not high during the pressure test and pressure holding process. Change, good sealing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com