A temperature self-regulating flameless combustion device

A flameless combustion and self-regulating technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve problems such as uncontrollable temperature and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

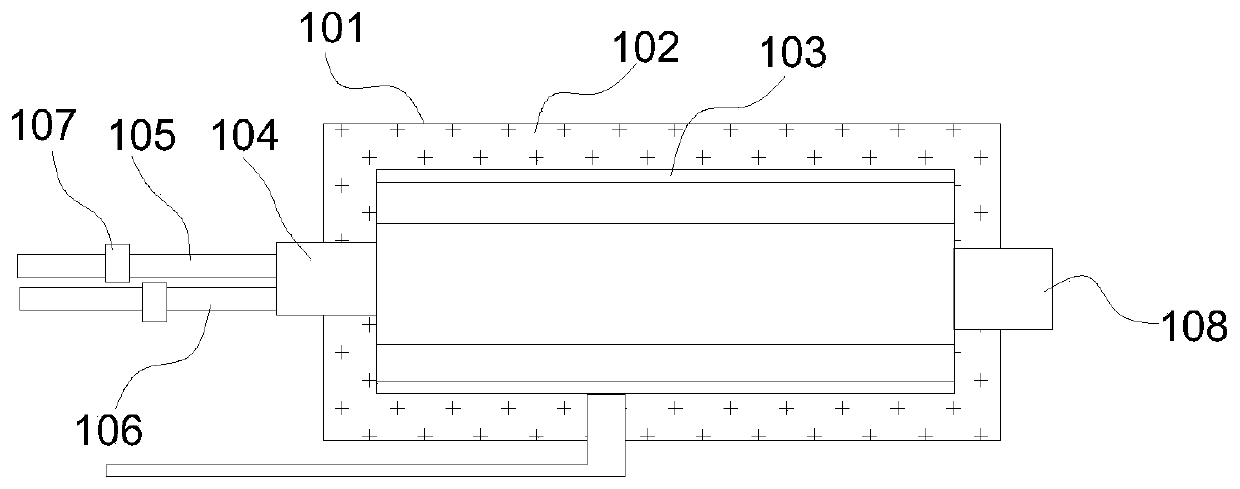

[0032] A temperature self-regulating flameless combustion device, see appendix figure 1 And attached figure 2 shown, including:

[0033] Furnace body, the furnace body is a horizontal furnace body structure, one side of the furnace body is provided with a fuel mixing zone 104, the side of the fuel mixing zone 104 is provided with a fuel input pipe 105 and an air input pipe 106, and the other side of the fuel mixing zone 104 is connected to the device. A plurality of flameless combustion tubes 110 in the furnace body are connected, and flow control valves 107 are respectively arranged on the fuel input pipe 105 and the air input pipe 106; From the outside to the inside, it is divided into the first reaction zone and the second reaction zone. A plurality of flameless combustion tubes 110 are evenly spaced on the edge of the first reaction zone. The first reaction zone is filled with a first medium 109. The first reaction zone A second reaction zone is arranged in the center o...

Embodiment 2

[0038] In this embodiment, on the basis of Embodiment 1, a pressure monitoring device is also provided on the furnace body. The pressure monitoring device can obtain the pressure information in the furnace in real time, avoid abnormal reactions, and help enhance the safety of the reaction.

Embodiment 3

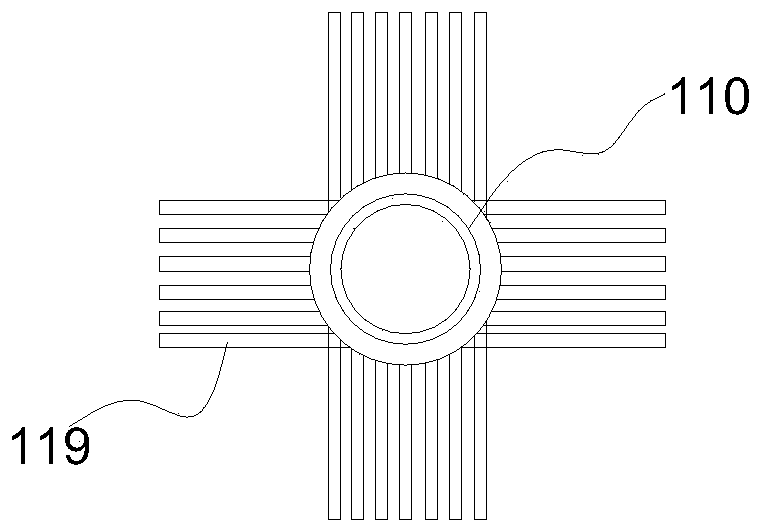

[0040] This embodiment is on the basis of embodiment 1, please refer to the attached image 3 As shown, the outer wall of the flameless combustion tube 110 is provided with a cross-shaped heat conduction fin 119, which increases the conduction area. During the working process of the flameless combustion tube 110, it releases a large amount of heat instantaneously, and the heat can pass through the heat conduction fin. Radiation transfer to the surrounding enhances the heat transfer effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com