A method for preparing nano-dielectric layer based on oxygen plasma process

A technology of oxygen plasma and dielectric layer, which is used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of affecting rectification function, interface defects, and high cost of device manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

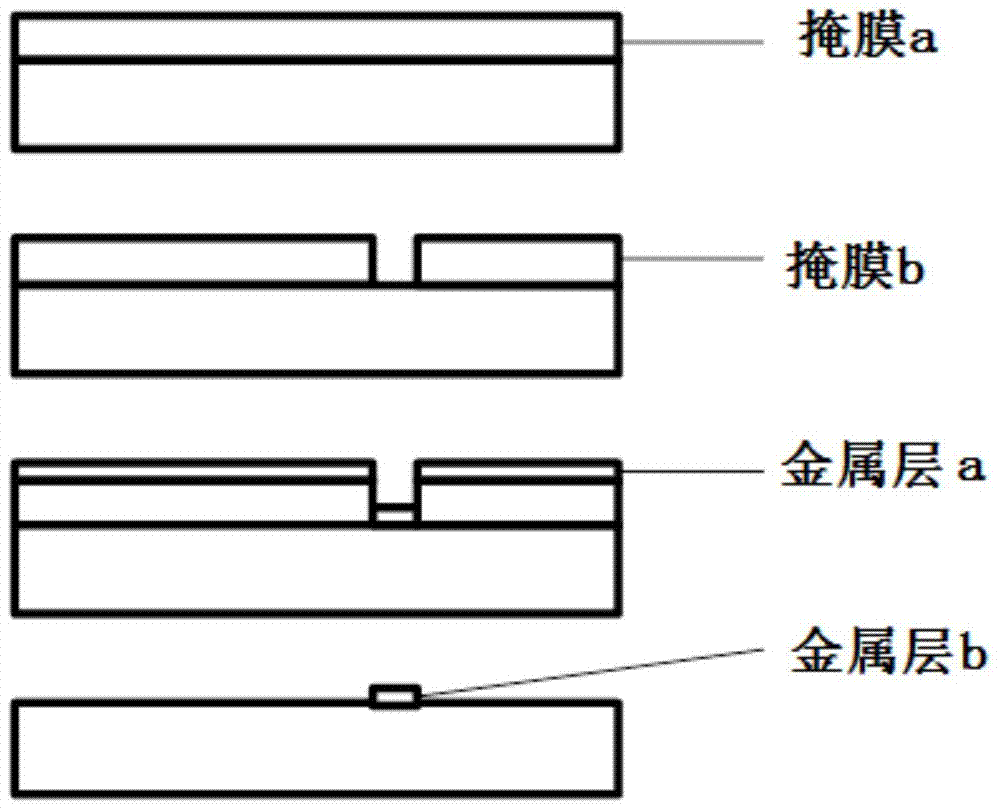

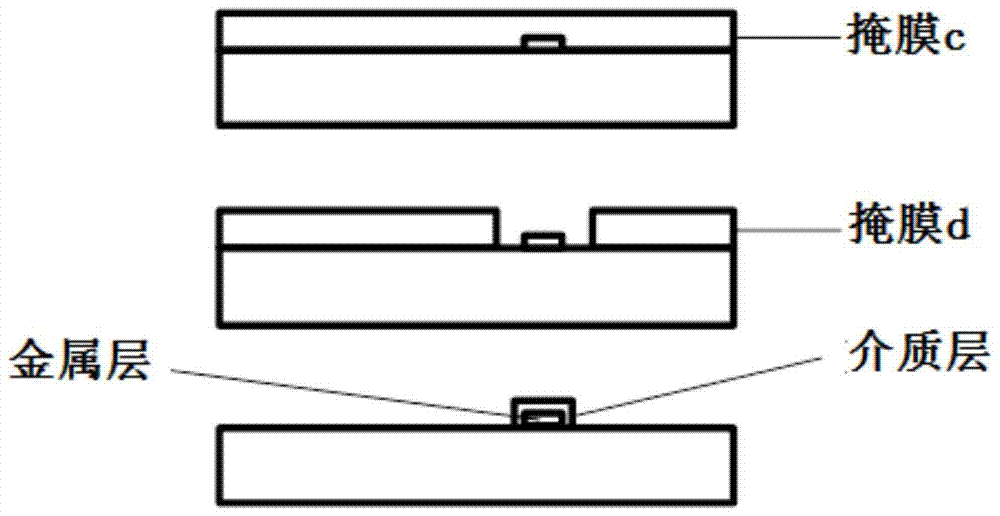

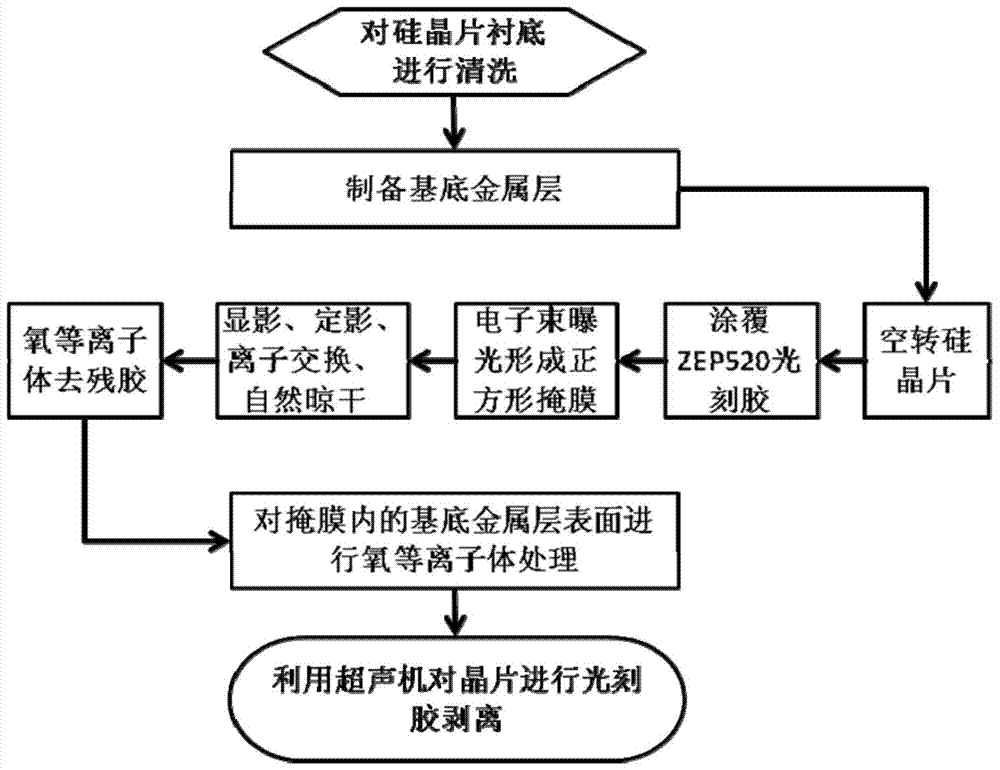

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing and two examples.

[0031] 1) Substrate cleaning

[0032] 11) The wafer used for the substrate is a silicon wafer with a 2 μm silicon dioxide layer. The specific cleaning steps are as follows: using an ultrasonic machine, soak the silicon wafer in acetone and sonicate at 40% power for 15 minutes, soak the silicon wafer in isopropanol and sonicate at 40% power for 15 minutes, wash it with deionized water, and dry it;

[0033] 12) Soak the silicon wafer in a mixture of concentrated sulfuric acid and hydrogen peroxide (5:1), heat it at 70°C for 15 minutes, and wash it with deionized water;

[0034] 13) Soak the silicon wafer in a mixture of water, hydrogen peroxide and ammonia (7:2:1), and heat at 70°C for 15 minutes;

[0035] 14) Soak the silicon wafer in a mixture of water, hydrogen peroxide and concentrated hydrochloric acid (7:2:1), heat at 70°C for 15min, wash with deioniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com